![]()

|

|

Working on the new Corvette

Part 1: Engine issues and proper jacking

by Hib Halverson

| It's hard to believe the fifth-generation Corvette has

been out a year. A total of 9752 '97s were built and, by the time you read this, at least

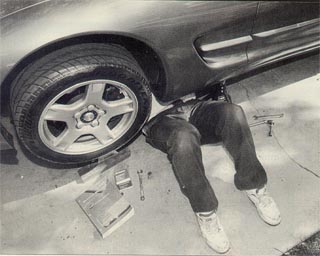

that many '98s should have rolled out of the Bowling Green Assembly Plant. After a platform change-over new owners who enjoy performing basic maintenance may be reluctant to roll up their sleeves and get working. With C5, this reluctance may be more pronounced because the car has more all-new pieces in it than any Corvette, even the 1953 model. The Technical Staff at Vette recently spent eight days with two 1998s, an automatic and a manual, and we are happy to tell you, while some procedures have changed and the frequency of periodic service has been reduced; Corvette is still a car that do-it-yourselfers (DIY) can enjoy. Our first recommendation is that any C5 DIY invest in the Corvette Service Manual of the appropriate model year. Unfortunately, the factory manual is an expensive set of three books totaling (1997 edition) 3890 pages and stacking 4 1/4 inches high. In spite of its cost and size, the Service Manual is a requirement if you want to understand and work on your C5. They are available through Chevrolet dealers and mail order sources, such as Mid America and Ecklers. Fluid checks, cooling maintenance, fuses and relays Pop the hood on a Gen. 5 'Vette for your first DIY session and you notice how much neater the underhood looks. The oil dip stick,, power steering fluid cap, brake master cylinder, coolant reservoir even the hydraulic clutch reservoir are easy for the DIY service technician to see and reach. Since 1992, Corvettes have used synthetic power steering fluid. Dealers sell the GM Parts brand (p/n 12345866 or 12345867). Red Line Synthetic Oil Corporation markets an excellent synthetic power steering fluid, as well. Do not use petroleum-based fluid nor automatic transmission fluid (ATF) in a C5 power steering system. The master brake cylinder is in the usual place. Just twist off the cap to inspect the fluid level. Brake fluid is in the C5 is conventional, glycol-based Delco Supreme 11¨ and meets the DOT3 specification. Do not use silicone-based, DOT5 brake fluids. They are not compatible with the car's antilock brake system (ABS) and can pose a safety hazard. Because no change interval is specified for brake fluid, many aggressive drivers never think about that, however, for highest brake performance; brake fluid should be changed every two years. Those running their C5s hard in road race or time trial events may want to change brake fluid more frequently and may even test the fluid using a device, such as the Mac Tools BFT900, which compares moisture content of a known-fresh sample to what is in the master cylinder. If the fluid fails the test, it should be changed. Road racers may also want to upgrade to a higher performance brake fluid such as Motul DOT 5.1. Like the factory-fill fluid, it's glycol-based, but its 509¡F dry boiling point and 365¡F wet boil exceed those of DOT3 and even 4 fluids by a significant margin. Additionally, the viscosity of Motul DOT5.1 is half that of DOT4 many fluids and a third that of DOT3 products. The lower viscosity enhances ABS operation. Fluid changes can be accomplished by bleeding each brake caliper such that clean fluid gets from the master cylinder to the caliper. Comprehensive brake bleeding instructions are in the Service Manual. Many people think brake fluid is used in Corvette hydraulic clutch systems. In the late-'80s, as a solution to squeaky clutch master cylinders, GM developed a specific clutch fluid (p/n 12345347) and it is specified for C5. Coolant put in LS1s at Bowling Green is a mix of 45% tap water and 55% ACDelco, "Dex-Cool," a unique ethylene-glycol antifreeze with a non-slicate, anticorrosive chemical package. Dex-Cool was jointly-developed by GM and Texaco and became factory-fill in most GM cars for the 1996 model year. Its non-silicate formula is longer-lasting and better for durability of cooling system parts than slicate-based anticorrosive packages in old-style antifreezes. Dex-Cool has an orangish-pink color. If small additions of coolant are necessary, tap water will suffice. If a large addition of coolant is required, first find the leak. Then add a 50/50 mix of distilled water and Dex-Cool. We suggest distilled water because tap water in some areas may be more acidic or alkali than than in Bowling Green. C5's coolant change interval is five years or 150,000 miles, whichever comes first. As good as Dex-Cool is, the Vette Technical Staff is unconvinced that interval is wise for best durability but has no evidence to dispute the Service Manual. We suggest changing coolant in LS1s at three years/90,000 miles. If you are changing coolant, mix Dex-Cool and distilled water at approximately a 50/50 proportion. Avoid antifreeze products other than Dex-Cool. If use of an antifreeze with a silicate anticorrosive package is unavoidable, as soon as Dex-Cool is available, drain the coolant, flush the system with water and refill with the Dex-Cool/water mix. An good cooling system performance upgrade is the addition of Red Line Oil's SuperCool. It consists of a chemical surficant or "wetting agent" that improves heat transfer from engine parts to the coolant along with a non-silicate, anticorrosive package. Adding SuperCool in the manufacturer-recommended proportion results in the coolant stabilizing at a lower temperature, once the thermostat is open. Other additives are unnecessary and do not use the "sealing pellets" recommended in past model years. They restrict parts of the cooling system and, due to improved technology in engine parts that come in contact with coolant, are unnecessary. Cooling system work may involve hot liquid. If the engine is at operating temperature, it is possible, upon removal of the coolant surge tank cap, the loss of pressure will cause explosive boiling in the system that has the potential for injury. The C5 tank cap is a threaded to allow simple pressure relief. If the cooling system is hot, turn the cap 1/4 of a turn. When the hissing stops, turn the cap further until it comes off. If the engine is running hot, say with a coolant temperature of 220 and above, allow the engine to cool before removing the cap. Changing coolant in a LS1 is a little more time consuming than it was with older Corvette engines because the engine block coolant drains are not accessible when the engine is in the car. The left drain is hidden behind the engine mount bracket and the right drain is behind the starter. Because of this you can't fully drain the system; you only can flush it. This work may also involve working with hot engine parts or hot liquid. We suggest you use some automotive work gloves such as "Mechanix Gloves" sold by Mechanix Wear. We like them because they protect hands but still allow good feeling. The radiator drain is at the lower, right corner of the radiator. Open it, let it run until the flow stops, close the drain and refill the system with water. Run the engine until the thermostat opens, shut off the engine, carefully release the pressure in the cooling system and open the radiator drain again. Repeat this procedure until the coolant coming out of the radiator runs clear. You may need to do this tedious flushing trick several times to get the water to run clear.Once the flushing is done, close the drain and fill the system with a 6.5 qts. of Dex-Cool (50%) and, optionally, a bottle of Red Line SuperCool. Add distilled water until it reaches the base of the surge tank neck. Start the engine and let it idle for a minute then cycle engine speed from idle to 3000 rpm and back until coolant temperature reaches 210¡F. Remove the tank cap, observing the cautions discussed previously. The coolant level should be about 1/2-in. above the "cold full" mark on the tank. If it is not, top off with distilled water, replace the cap, start the engine and repeat the above procedure. Most C5 fuses, circuit breakers and relays are away from engine heat in a compartment behind the right front wheel next to the battery. The PCM is in yet another cavity under the battery. Removing the right wheel well filler panel exposes it. Additional fuses and circuit breakers, mainly interior and instrument panel cluster (IPC) items, are located under an easily removable panel at the front of the passenger side footwell. The alternator on a C5 is the dependable, ACDelco CS130D series unit. CS130Ds are quite durable, but should you ever have to replace one, the job is easy. The alternator is driven by the customary serpentine belt system, but the LS1 uses two belts, one for the HVAC compressor and the other for the alternator and other accessories. A great performance upgrade, when they become available for C5s, will be a set of Goodyear's Gatorback Poly-V belts. Their unique design allows them to run cooler than OE-Belts and that extends their lives. The air filter element is contained in an easy-to-open housing in front of the radiator. The factory element is an ACDelco A917C. It should be inspected every 10,000 miles and replaced, if necessary. A common performance upgrade is the oil-impregnated, gauze filter (p/n 33-2111) from K&N Engineering. While the initial expense of the K&N may be higher, eventually it becomes a better value because all K&Ns are reusable. Inspect it every 10,000 miles. If it is at all dirty, simply remove it, clean it, reoil it and put it back in place. Jacking the C5 Most C5 DIYs will raise their car with a hydraulic service or "floor" jack. Do not use a floor jack to support the car while working underneath it. Hydraulic jacks can fail. If that happens while you are under the car; it is unlikely you will live to enjoy your C5. Use the floor jack only to lift the car. Use jack stands to support it. The floor on which you are going to work must be reasonably level. If you are going to get both ends off the ground, start with the front. If you do the rear first; you won't be able get the jack under the front. All the lower control arms mount to a pair of robust aluminum castings called "suspension cross members". They bolt to the car's structure and are the easiest jacking points when a floor jack is used. Each is a rectangle formed by two longitudinal rails and two cross-car rails. Do not, under any circumstances, use the front or rear leaf springs as jack points. To jack the front, drive the front wheels up on wood blocks that are at least 12-in. long, 3.5-in. wide and 1.5-in. thick. Some floor jacks have a tall frame and thicker blocks may be necessary. With a C4, after you rolled the front up on blocks, you usually had to turn the front wheels full lock and roll the jack in from behind a front tire. Because of C5's longer wheelbase, you can lift the front by just rolling the jack under the nose. Jack the front with either of the front suspension

crossmember's two, cross-car rails. Each rail has two reinforcing ribs. To lift the car

without damaging the crossmember, the jack's lifting pad must

In the back, jack the rear suspension crossmember's rear most cross-car rail by spanning its two reinforcing ribs with the jack pad. Looking at the back of the car, the two rear ribs will be on the first ribs you see. Do not jack the front cross-car rail's single, reinforcing rib. Doing so will damage the vehicle.

All floor jacks are not alike. Working on '84-'96 cars, we've had trouble with jacks having high pick-up heights. In researching this story, we stumbled upon a great two-ton floor jack (p/n W93642) made by Lincoln Automotive. It has advantages that made it the jack of choice in our shop. The Lincoln's jack pad is lower (3.75") than those of others we have used. Driving the front up on blocks is still required, but the blocks can be small. Other jacks require a larger elevation of the front wheels. The Lincoln has low side frames. This is important when you not only need a low jack pad but the rest of the jack needs to be short enough to not interfere with the front air dam. In our jack search, we found some with acceptable pad height but with other parts too high to get under the car. Lincoln's hydraulic and mechanical design provides

significant upward movement with small Once you have either end of your C5 up on a floor jack,

place your jack stands. If you look at the bottom of each hydroformed, perimeter frame

rail, near where they turn inboard to clear each wheel, you will see a welded-in ('97 and

early-'98) or riveted-on (later-'98s) circle of steel with a slot in it. These

"shipping slot reinforcements" are used to hook the car onto the truck that

brings it from Bowling Green. Stands should be placed such that those reinforcements rest

on each stand's support pad. Do not allow the surrounding rocker panel material to get

stuck between To learn how to lift a C5 with a hoist and to get the car up high enough to photograph jacking points and other items under the car, we took a '98 we borrowed from Chevrolet to Auto Masters, an independent Corvette service facility in Palm Desert, California. Auto Masters is the home of the "Street Skinner" engine package for ZR-1s and is known to enthusiasts in the southwest as "The Corvette Tech Center" for its specialized service of America's Sports Car. Auto Masters has several above-ground, frame-contact hoists

having arms that come in from the side. If you are lifting the car with a hoist like that,

position its contact pads under the shipping slot reinforcements. In the front, this is

easy because the rocker panel cutouts are large. Turn the pad such that its long side is

parallel to the frame rail and the reinforcement centers on one end of the pad. It can

overlap but not lift on the floor panels inboard of the frame. Do not allow the rocker

panel material to get pinched between the hoist pad and the frame. Lifting the rear shipping reinforcements with the pads used on most hoists is impossible because the rocker panel cutouts are not large enough. A pair of blocks, small enough to fit inside the cutouts, is required. We made them out of one-inch thick pieces of 2.25-inch diameter, aluminum, bar stock. We have seen similar devices made by C5 owners out of one-inch thick blocks of hardwood, 2-2.5-inches on a side. Be they aluminum or wood, place the blocks on the hoist pads. Position the pads such that the blocks contact the shipping reinforcements but not the rocker panel material. Then, raise the car. We did not have access to a single post "drive over"Hoist, however, if you find one that clears the C5s underpinnings, the hoist pads should be positioned as discussed above. During research for this article, GM Service Technologies Group (STG) told us Kent-Moore, the company that distributes GM service tools, will be releasing a device designed to address problems with lifting C5s with hoists. It will be similar in concept to the blocks we made but will twist-lock into to the shipping slots. If you are lifting a C5 with a twin-post, suspension contact hoist; position the front lift such that it catches the outboard ends of the front lower control arms just inboard of the lower ball joints. Position the rear lift under the rear tires. Oil and Filter Changes The 5.66-liter, LS1 V8 engine used in C5s was an all-new design for 1997. Other than connecting rod bearings and hydraulic lifters, the "Generation III V8" shares nothing with the Small-Block V8 used from 1955 to 1996. In spite of that, changing the LS1's oil is not much different than changing the oil in Corvette engines has been for 43 years. Jack the car up and support it such that the rear end is just a bit higher than the front. You can do this by setting the rear jack stands one hole or notch higher than the fronts. If you are changing oil while the engine is still hot, consider wearing Mechanix Gloves. The LS1's drain plug is at the front of the "bat wing" section of its oil pan. The pan holds six quarts so make sure your drain pan holds two gallons. Remove the plug and allow the oil to drain for 7-10 minutes. Once the oil is drained, wipe the drain plug and its sealing surface on the pan with a clean rag, replace the drain plug and tighten it to 18 ft/lb. The oil filter is an ACDelco PF44. It's of the general design used on Corvette engines since 1968, a cartridge-type, "spin-on" unit. The filter is partially recessed into the oil pan casting. Removal is easier with an oil filter wrench. The best choice is a cap-type unit, such as the ACDelco (p/n OF17W). A strap-type wrench with a swivel handle will also work. Installing a PF44 requires no new skills. Wipe the gasket surface on the engine with a clean rag. Fill the new filter with your engine oil of choice, smear some of that oil on the gasket, screw the filter onto the block, then tighten it 3/4 to 1 turn after the gasket contacts the filter mount. Open the hood, remove the oil cap, add six quarts of new oil and replace the cap. Set the emergency brake, start the engine, run it for about three minutes then shut it off. Crawl back underneath and inspect the filter and the drain plug area for leaks. Wait three minutes then check the oil. If necessary, add additional oil to bring the level in the crankcase up to the "full" mark on the dip stick. Get the car back on the ground and you're done. How often should you change the oil in your C5? First, ignore the "quick stop" lube and oil service industry's irresponsible marketing of 3000 mile oil changes. For any Corvette driven in a normal duty cycle, even one that sees occasional drag racing or autocross, changing the oil every 3000 miles is a waste of time and money. Modern oils, especially the synthetic in the LS1, are far more durable than the 3000 miles the Jiffy Lube folks want us to believe. If the car is operated normally, (and that means with aggressive driving at times) and you use a synthetic oil meeting the American Petroleum Institute Service SJ standard, the best thing to do is observe the GM's oil change interval. Since 1990, Corvettes have been equipped with a computer device called an "engine oil life monitor" that records, since its last reset, number of engine starts, number of engine revolutions, coolant and oil temperatures and some other data. It can display on the IPC oil life remaining and will turn on the "change oil" light when the its programming determines the oil life has been depleted. When that light comes on, GM wants you to change the oil and filter. This will usually occur sometime between 3000 and 10,000 miles since the last oil change, if the monitor was reset at that time. In cases of severe duty, it may come on before 3000 miles. It will never come on at more than the maximum oil change interval allowed by GM for the LS1 engine: 10,000 miles. Wondering about the longer change interval? GM Powertrain Division has decided that the durability of synthetic oils, the LS1's lower oil and coolant temperatures, its increased oil capacity and significant testing made extending the maximum oil change interval from 7500 to 10,000 miles acceptable. Our own experience with Red Line Synthetic oil and extended drain intervals show, clearly, the LS1's 10,000 mile change interval is prudent and, perhaps, even conservative. What may not be prudent is the oil filter change interval. The PF44 uses the excellent, "Duraguardª" synthetic filter media but is of rather small capacity. The technical staff at Vette suggests, while you observe an oil change interval of 10,000 miles, you change your oil filter at least every 5000 miles and preferably (since filters are cheap insurance) every 2500, regardless of when you change the oil in the crankcase. Several times a year ACDelco runs promotions with mass-marketers that have filter prices really cheap. Wait until then and stock up. The C5's oil life monitor cannot analyze the oil. It makes an "educated guess" at its condition by measuring trends in engine operation, thus, it can not detect dust in the oil. If you drive your Corvette on a regular basis in dusty areas, change the oil and filter every 3,000 miles or 12 months, whichever comes first. The oil life monitor also cannot read the calendar. If your C5 has gone 12-months but less than 10,000 miles since its last oil change and the change oil light has not come on, change the oil and filter and reset the monitor. Information on how to display oil life remaining and resetting the monitor is in the Service Manual. Spark Plugs C5ers who've worked on C4s with LT1/4 engines will breath a sign of relief. The LS1's design and its underhood packaging make plug changes easier. In fact, the time required, the complexity and the tools necessary approximate that of the old, no-air, big-block C3s of the '68-'74 era. All but the plug in #7 cylinder are quite easy to change and the tough part about #7 is not pulling the plug but getting the boot off. Because of the closeness of the brake booster and the AIR lines, getting good leverage with your fingers is tough. We were able to remove it from above, but others may find the it easier removing it from underneath, a time-honored trick of big-block owners. All the spark plugs can be removed with a 3/8-in. drive plug socket, a universal, an extension and a spark plug ratchet. We don't put much credibility in GM's claim of 100,000-mile durability of platinum-tipped spark plugs when they are installed in a high-performance engine driven regularly in its intended duty cycle. The GM warranty for exhaust emissions related items (spark plugs included) is only 50,000 miles and our experience in the field has been, since GM introduced double-platinum plugs in Corvette engines for 1992, that they are good for about 35,000 in an engine that's regularly driven hard. Nevertheless, that's still better than one can expect from non-platinum plugs. OE in LS1 is the AC 41-931. They were new for 1997 and are what ACDelco engineers call the "High Efficiency II" Design. They are a 5/8-in. hex, 3/4-in. reach, conical seat plug that uses a platinum pin center electrode and a platinum "puck" that is laser-welded to the ground electrode. The 41-931 is an AC "2" heat range plug and is acceptable for light competition duty. The aftermarket has yet to make available performance spark plugs specifically for the LS1 and we suspect it will be several years before it does, however, C5s that see a serious road race or time trial duty may run better with a slightly colder spark plug. In addition, aftermarket sources are working on both supercharger and nitrous oxide injection packages for C5. Generally, those modifications work best with a colder spark plug, especially on the drag strip. For the Gen. III engines, there are no resistor plugs available right now in colder heat ranges. However, NGK has non-resistor plugs available in its standard and V-Power Racing lines. In road race, blown or nitrous motors, we suggest the NGK BP7EFS as a start and the R5724-8 for a real aggressive engine. The LS1's stock plug gap is .060-in. That may be hard to achieve with some non-AC plugs. A gap of .045-.050 will work, but a small degradation in idle quality may result. Understand that use of non-resistor spark plugs may cause ignition noise to become audible through the sound system. Additionally, use of NGK 8 heat range plugs on the street is not advised. Vette Magazine would like to thank Karen Kincaid and Tim Pierce of the GM Service Technologies Group, Corvette Service Readiness Team; Darcy Traynor of GM Service Part Operations, Media Relations and Roy Howell at Red Line Synthetic Oil Corporation for special assistance in preparing this series of articles. Next month, we will cover brake pad changes, transmission and axle fluid checks and changes, basic computer diagnostics, a few other maintenance items and a brief look at aftermarket accessories for the C5. |

Sources:

| ACDelco see your Chevrolet dealer or ACDelco retailer www.acdelco.com |

Auto Masters 77-700 Enfield Ln. Unit A Palm Desert, CA 92211 760 360 VETT |

| Eckler's

Division of Smart Choice PO Box 5637 Titusville, FL 32783-5637 800 327 4868 www.ecklers.com |

GM Service

Technologies Group (service manuals) see your Chevrolet dealer |

| Kent-Moore

Div. SPX Corp. 28635 Mound Road Warren MI 48092 800 345 2233 |

Lincoln

Automotive 1 Lincoln Way St. Louis MO 63120-1578 800 245 3862 |

| Mac Tools Box 32940 Columbus OH 43232 800 848 6500 |

Mechanix

Wear 24950 Anza Dr. Valencia CA 91355 805-2576-0474 www.mechanixwear.com |

| Mid-America

Designs, Inc. Box 1368 Effingham IL 62401 800 500 1500 www.madvet.com |

Mobil Oil

Corporation see your Mobil 1 retailer

|

| Motul USA,

Inc. 790-C Indigo Court Pomona CA 91767 800 926 6685 |

NGK Spark

Plugs, USA 22 Mauchly Irvine CA 92618 714 855 8278 |

| Red

Line Synthetic Oil Corporation 6100 Egret Court Benicia CA 94510 800-624-7958 www.redlineoil.com |

|

What Kind of Oil?

| Since 1992, the factory-fill oil in Corvette engines, except '92 LT5s, has been a synthetic, 5W-30. Prior to that, as far back as the late-1970s, GM used a petroleum-based 5W-30 in Corvettes, except '90-'91 ZR-1s. The reason GM recommends 5W-30 is it's the politically correct choice when fuel mileage is a prime consideration. The U.S. Environmental Protection Agency, which oversees fuel economy standards for cars sold in this country and believes 5W-30 oil is a significant energy conservation measure, pressures car companies into 1) using 5W-30s in new vehicles and 2) marketing them to service customers. In response to this pressure, many years ago a policy was made by GM at the corporate level that, with few exceptions, the recommended oil for all passenger vehicles be 5W-30. When you read the "Maintenance and Lubrication" section of the 1997 Corvette Service Manual carefully, you soon find there are alternatives. The book states on page 0-47, "The recommended SAE engine oil viscosity is 5W-30, however, if the temperature is above -18¡C (O¡F) 10W-30 may be used." Not only is this true for C5 but the same or similar language appears in owner's or service manuals going back a decade or more. While we dispose of used oil and filters responsibly, recycle our cans and plastic and keep our room air conditioners set for 78¡, the Technical Staff of Vette Magazine cares little about the fraction of a percent better fuel mileage we supposedly gain with 5W30 oil in our Corvettes. It is our opinion that high-performance engines regularly operated in above 0¡F outside temperature and in their intended duty cycles will maintain performance longer if an oil of different viscosity range is used. Any 5W-30 engine oil, including the synthetic in C5s, uses chemical additives, called "viscosity-index (VI) improvers", to widen its viscosity range enough to make it a 5W-30. VI improvers contribute little to lubrication and can make a "multi-vis" oil less effective at high temperatures than an oil without them. This can become a problem when the oil is under high shear loads at temperatures above 225¡F. It becomes a potentially damaging problem when oil temp. approaches 300¡F. If your oil temperature in the pan is 250¡F or above, bet that oil temp in bearings is approaching 300¡. Near the piston ring lands and the upper sections of the cylinder walls, it is that or above. Another characteristic of a 5W-30 that can be a problem in severe service is a relatively high evaporation rate at high temperatures compared to lubricants of more narrow viscosity range. A higher evaporation rate contributes to increased oil consumption and substandard lubrication in areas of high temperature. There are no VI improvers in quality, 10W-30, synthetic engine oils and their high-temperature evaporation rate is less. Thus, 10W-30 synthetics are better lubricants in severe duty applications. For that reason, we recommend that any C5 owner, and, for that matter, the owner of any Corvette built since GM began telling us to use 5W-30Ñput a synthetic, 10W-30 oil in their engine. A good choice is Mobil 1, 10W-30 synthetic. An even better choice is Red Line Oil's 10W-30. While it is a good product, to keep its cost reasonable, Mobil 1 is made with a synthesized-hydrocarbon, base-stock. Red Line uses a more costly, but higher-performing polyol-ester base stock as used in jet engine lubricants. Because of this, Red Line 10W-30 due has slightly better anti-friction characteristics and is capable of lower oil temperatures at a given ambient temperature and engine load. Additionally, at oil high temperatures during severe duty operation, Red Line offers more scuff protection when lubricating main, rod and cam bearings. The second oil selection issue to address is the Service Manual statement that LS1s operated in North America use only an oil meeting GM Standard 4718M. The Manual also states that oils meeting 4718M might be hard to find outside North America and that LS1s operated in such places can use any 5W-30, 10W-30 or 10W-40 petroleum or synthetic oil meeting APIÊSJ and Association des Constructuers Europeens de l'Automobile (AECA) Standard 3-96. In a survey of some mass-marketers selling major brand synthetic oils to the DIY, we found synthetics may or may not be labeled as meeting GM 4718M but all meet the American Petroleum Institute's (API) Service SJ and International Lubricant Standardization and Approval Committee (ILSAC) GF-2. Using information provided by the the GM Powertrain Division and the Lubrizol Corporation, a chemical manufacturer that sells raw materials to the world-wide oil refining industry, we researched these different oil specs.. GMPT supplied the particulars of 4718M and Lubrizol's web site (www.lubrizol.com) had the test sequence requirements for API SJ, ILSAC GF-2 and AECA 3-96. SJ and GF-2 have only minor differences, none of which affect the ability of oils meeting those specifications to lubricate. 4718M and 3-96 are similar, however, both differ from API SJ and ILSAC GF-2 in two critical measures: 1) the GM and the AECA standards require better performance in high temperature/high shear environments, two conditions present in any engine generating very high oil temperatures and 2) both 4718M and 3-96 require a lower oxidation rate, also a necessity in an engine generating high oil temperatures. Those differences mandate synthetic oil because petroleum-based oils cannot meet the higher requirements. Better high temperature/high shear numbers and lower oxidation rates are characteristic of all quality synthetic oils. The Vette Technical Staff suggests C5ers looking to buy oil for their LS1s not worry so much about 4718M and look for a major brand of 10W-30 synthetic oil meeting API SJ or ILSAC GF-2. Examples are Red Line, Mobil 1, Castrol Syntec and Havoline Formula3 Synthetic. Those operating their Corvettes outside North America should use an oil that meets AECA 3-96. |