| Ruthless Pursuit of Power: The Sequel |

Page2 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

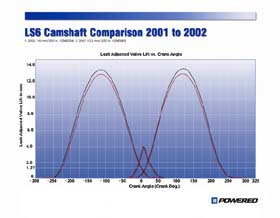

LS6 Evolution: Bigger Cam–Again There are two big changes in LS6 for 2002. The first is evolutionary and the second is revolutionary.

LS6 Camshaft: Intake Comparison

To preserve idle stability, the MY02 intake duration at .050-in lift was held to the ’01 specification. Idle quality is a pleasability issue with Corvette customers, but more importantly, it impacts exhaust emissions. For LS6 to meet the national low emission vehicle (LEV) standard, it’s got to idle smoothly. With the intake duration frozen, the only way to increase air flow and, thus, performance was to add valve lift. The exhaust duration at .050 lift was lengthened and valve lift was added. Both increased exhaust port flow. Another change made to preserve idle quality was to spread the lobe centerlines apart. "We spread them by retarding the intake lobe two degrees and advancing the exhaust one degree," Jim Hicks said. "Typically, when you delay the intake closing point, you give up a little torque at low speeds, but it doesn’t hurt power. In fact, if anything, it might help power a little bit. "The main reason why they were spread like that is: with the longer exhaust duration, we had to spread the lobes to maintain overlap at the ’01 LS6 level so the idle quality wouldn’t be degraded. "There was no downside from a power perspective and the torque really wasn’t hurt either. We made up for it in the additional lift area."

The ’01 base circle reduction did not require a change in dimensions of any other valve train part, however, the 405-horse cam was a different story. "I wasn’t comfortable reducing base circle that much," Hicks told us, "without compensating for it somehow, because the position of the plunger within the hydraulic lifter is not optimal any more–you’re too high in the lifter. "There’s different ways to correct the geometry. The one we selected to minimize the impact on our manufacturing operations was to increase the length of the valve. The valves in the 02 LS6 are 0.6-mm. longer than the valves in all other Gen III engines." With .025-in more intake lift, the same intake duration at .050-in but a little less duration at lash and the same rev limit; something had to be done to the rest of the valve train to keep it in control at high rpm. While the ’02 exhaust lobe doesn’t have quite the aggressive profile as the intake, it’s still got more lift, so something had to be done there, too. The choices GM made were to decrease valve weight and increase valve spring pressure. "With the higher lift, we needed to reduce the mass of the valvetrain or start getting into a float condition," John Juriga commented. "We went to hollow stem intake and exhaust valves, very similar to what we used in the ’96 LT4. We pushed the edge with a state-of-the-art, 0.8-mm. (valve stem) wall thickness–very thin stuff. The exhaust stems are sodium-potassium filled."

A bigger cam, lighter valves, stiffer springs–so goes the ruthless pursuit of power. And–what’s this new camshaft and valve train stuff worth, by itself? Jim Hicks: "You can do a direct a-b and there’s an easy 8-10hp there, whether you change the back-pressure or not. There are other changes in the ’02 package–exhaust system and induction system–which increase the power more. The overall power increased about 20hp and the cam was half of it. Again, that’s because it’s a short-duration design with low overlap so it’s not really affected that much by back-pressure. "In fact, we ran the ASA (the American Speed Association, an oval track racing spec. series that uses a modified version of the LS1) cam, back-to-back with this ’02 LS6 cam. If you don’t change the exhaust system, you only pick-up 2 hp with the ASA cam, but if you drop the back-pressure to something near zero (ie: a racing exhaust), then it’s more like 20hp. So, that’s the back pressure effect I keep talking about." What about that ASA cam? It’s got only .525-in. lift but, at .050-in., it’s got 226° intake duration and 5.5° overlap versus the LS6’s 204° and no overlap. Clearly, it’s designed for higher rpm and more power but it needs a very low restriction or open exhaust. Will it work in a hi-po street LS6? Well–kinda sorta. Once you get the cam and the right valve train pieces, the biggest problem comes if you have to remain emissions legal. Getting the engine to run with the ASA cam but without the OBD2 diagnostics blowing codes would be a challenge you have to tackle–but only after you design a cat converter set-up and exhaust system that has low enough back pressure such that the ASA cam’s potential can be realized. What about updating ’01 LS6es with the ’02 cam? Don’t do it, unless you add the ’02 valves and springs. Why? "The biggest issue is:," Jim Hicks stated, "without the lightweight, hollow-stem valves, you loose about 300-400 rpm in limiting speed. If you continue to run the LS6 calibration, where the fuel cutoff is 6600 rpm; you’re gonna be running into some significant valve train distress at 6200-6300 rpm. I have no idea how durable that combination is going to be over time." |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| LS6

Revolution: Pups Out, New Cats In |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||