|

Page-4

2001 Corvette Z06 by Hib Halverson

Downstream of the Engine

New

Corvette engines usually bring changes to the rest of the powertrain and

that had me talking to Bill Zabritski, GMís Design Release Engineer

for manual transmissions and rear axles in performance cars. Iíve

known Bill since he worked on the ZF S6-40 development in the mid-í80s

for C4 and heís a passionate believer in the Corvette.

Zabritski

told me, to accommodate LS6ís increased torque, clutch pressure was

increased but pedal effort was held at a comfortable level. All C5

driveshafts are now 6061 aluminum and .315-in. larger in diameter.

Driveshaft couplings for Z06 and other stick-shift cars are upgraded

from last year.

All

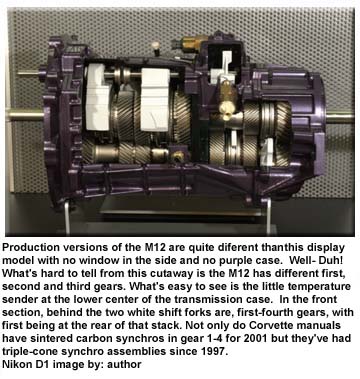

Z06es have the Tremec six-speed manual transmission. According to

Zabritski, for í01, forward gears in all C5 manuals get sintered

carbon synchro rings as a durability improvement. Zabritski also said

Z06 uses a specific "M12" version of this transmission having

higher ratios in the first three gears (2.97/2.07/1.43 vs 2.66/1.78/1.30)

which makes the M12 a wider-ratio trans than the MN6 used in

Coupes and Convertibles. With the LS6ís flat

torque curve, Zabritski and the Corvette engineers found the

Zed-ought-six was quicker with higher ratios in the first three gears.

One problem is C5ís limited transmission and rear

axle cooling. This is a function of the carís front air dam and smooth

undercar aerodynamics. M12s get a temperature sensor that turns on a

"trans overtemp" light when trans oil gets above 325į F. At

that point, as Chevroletís press kit says, "...thermal loads

become excessive..." and "...the transmission could be damaged

if not allowed to cool down." This sensor has been standard on C5

manuals sold in Europe since 1997.

The overtemp light reminds us General Motors is still

a big company where executives sometimes make compromises. GM is aware

of the high transmission and rear axle temperatures sustained by C5s

used in motorsports applications, yet, on the Z06, which by Chief

Engineer Dave Hillís own admission, is marketed to the "extreme

performance enthusiast"; we get a temperature warning light. What

the M12 needs is either a lubricant better suited to high temperatures,

such as a synthetic like Red Line or, better yet, a transmission cooler.

Apparently, neither are very attractive for factory use, presumably,

because of cost, however, an aftermarket transmission cooler, developed

for C5 racing applications, is listed in the 2000 GM Performance Parts

Catalog.

The rear axle assembly used in the Z06 is generally

the same unit (3.42:1 ratio with limited slip differential) manufactured

by Getrag and used by all C5 manuals since 1997. It has one difference:

a shotpeened ring and pinion. Bill Zabritski told me this adds an extra

margin of reliability to a powertrain having increased torque output.

Zed-ought-six does Weight

Watchers: Next |