|

Anti-Squat Bracket

sequence

|

|

|

|

Once prep'ed for welding, each bracket is

pushed onto the lower control arm pick-up point on the

rear axle. A "Ford adjusting tool" (a dead blow hammer

works just fine) may be needed to tap the bracket in

place.

|

|

|

Eric Norrdin, at work on the Tom Henry RS

abrading the parts of the rear axle housing onto which

the bracket will be welded. Eric gets a "happy star" for

taking on a dirty job on a brutally hot and humid day in

the Development Engineering Department at Global West.

|

|

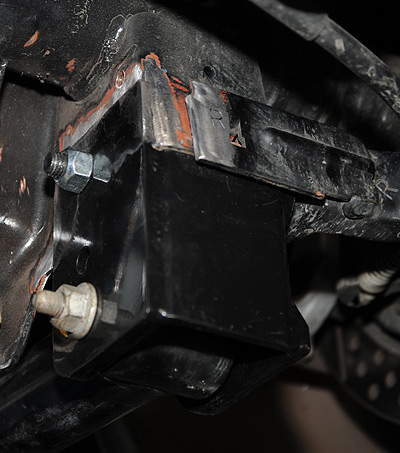

The right side bracket, bolted down to hold it

in place and ready for welding.

|

|

|

The brackets are welded on the side, the

rear and in their interior. Eric used

Global West's Miller MIG welder to do the work.

|

|

|

The right side Bracket, after welding was

complete.

|

|

|

The right Bracket, all bolts tightened and

fresh black paint.

|

|

|

The left Bracket along with the Global West

Lower Control Arm.

|