|

Building the Tom Henry RS

Pt 3:

Engine Assembly, Driveline Mods, Brake Upgrades and...Dyno

Testing.

|

|

|

Image: CHpg Staff |

In the last part of the

THRS series, we had DeGroff's Cylinder Head Service

build us a pair of street high-performance, 3800 Series

II heads and we installed a Comp Cam and lifters.

In this part of the

story, we're going to finish off the engine. Next, we're

going to add some HD parts to the driveline appropriate

for our modified engine's torque output and do some

upgrades to the car's brakes. Finally, we'll go to the

chassis dyno to validate our work to date.

Heads On

|

|

|

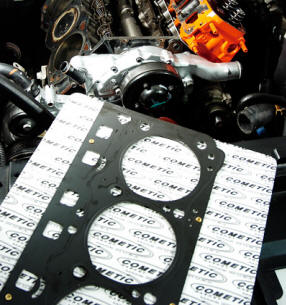

While the engine in the

Tom Henry RS is not supercharged, a

common use for MLS gaskets is boosted

engines. How much boost? With a stock

gasket, you're lucky to hold

half-a-dozen or so pounds boost whereas,

with a Cometic MLS gasket, it is not

uncommon for users to report 40 pounds

of boost without the use of o-rings.

Image: CHpg Staff. |

|

Combustion

chambers grow slightly in the valve unshrouding

and polishing processes and that decreases

compression ratio. To recover some of that, we

ordered Cometic head gaskets (PN H1773052S,

left, H1772052S, right). The Cometics are .052"

thick or about .011" thinner than stock and good

for about a tenth of a point more compression.

Hopefully, that will bring us back up to where

we were before we did the heads.

For the last

decade or so, Cometic Gasket, Inc. has promoted

multi-layered steel (MLS) head gaskets for

street high-performance and racing applications

of many engines, including the 3800. Initially,

the introduction of this type of gasket

generated mixed response. Some were disbelieving

that a set-up of stainless steel layers with

strange little bumps could seal their engine.

Today, the MLS design is widely accepted by

engine builders and being used in place of the

typical composite and/or copper designs. it is

also being use by O.E.'s in high-performance

applications, such as the 620-hp LS9 engine in

the Corvette ZR1. |

Multi-layered steel

offers benefits which cannot be attained with standard

head gaskets. The stainless in an MLS gasket withstands

temperatures in excess of 2000°F, about twice what a

standard gasket can take. Because they are the same

material throughout rather than most OE gasket's

steel-fire-ring-and-fiber composition; they don’t cause

as much bore distortion.

Some other benefits of

Cometic's design? Since it's not limited by the size of

the steel fire ring commonly found around the bores in

an OE gasket, a wide variety of custom bore sizes and

thicknesses are available. Need a thicker gasket to

modify your compression ratio or add piston-to-valve

clearance? Not a problem. Need to accommodate your

strange sized overbore? Chances Cometic can make what

you need with a short turn-around time.

|

|

|

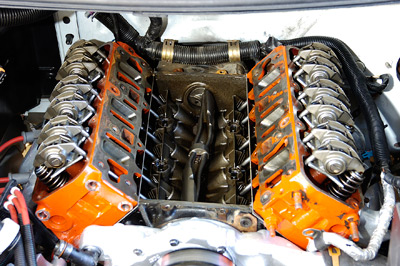

In spite of a 4th Gen

car's restricted underhood space,

getting the heads on-and-off a V6 is not

difficult because of the engine's small

size.

Image: CHpg Staff. |

We cleaned the bolt

threads in the block, scraped the decks, used a shop vac

to suck out any debris in the cylinders then wiped the

bores and the decks with MEK. We set the Cometic head

gaskets on the block decks then lowered the right head

onto the block. Next we installed the coil pack mounting

bracket to the left head because it's much easier to

tighten its bolts with the head off the engine. After

that, we dropped the left head on the block.

|

|

|

611.04) Important to the

reinstallation of the 3800's top end are

a torque angle meter and an inch-pound

torque wrench. A tool like the Mac Tools

Torque Angle meter (PN TM281N at right)

is required for tightening head bolts.

We used a Mac Tools inch-pound torque

wrench (PN TWDFX150N, at left) for

tightening upper and lower intake

manifold bolts.

Image: CHpg Staff. |

|

|

|

611.05) Many GM torque

specs list an initial figure, to which

you tighten using a torque wrench, and a

final torque angle number. The angle

meter goes between your ratchet and the

socket. The scale is fixed with the

clip. The pointer moves with the socket

and you read the angle on the scale. A

torque angle meter can be a little

difficult to use, mainly because of

awkward positions you get into trying to

apply torque without screwing-up the

measuring process. What we'd like is one

of the digital electronic torque angle

meters but, when we found out how much

they cost; we had to live with the

straight mechanical unit. Image: CHpg

Staff. |

The 3800's cursed,

torque-to-yield head bolts can only be used once, so we

installed a new set of Fel-Pro head bolts (PN ES74033).

A torque angle meter must be used for final head bolt

tightening. It's a difficult process, but stay calm–it

just takes time. Those of lesser strength may need to

squat on the front stabilizer bar, between the engine

and the radiator, to tighten some bolts. Use the

tightening pattern listed in the factory Service Manual.

|

The combination

of our Comp cam's smaller base circle and

thinner head gasket require a 7.000" pushrod.

Because we're going to buzz this motor to 6200

rpm, we ordered a dozen of Comp's Hi-Tech units

(PN 7936). Made from .080" wall-thickness,

seamless chromoly steel, they are 5/16" diameter

and a ton stiffer than O.E. pieces. We dabbed

Red Line Assembly Lube on each end then dropped

the pushrods in place.

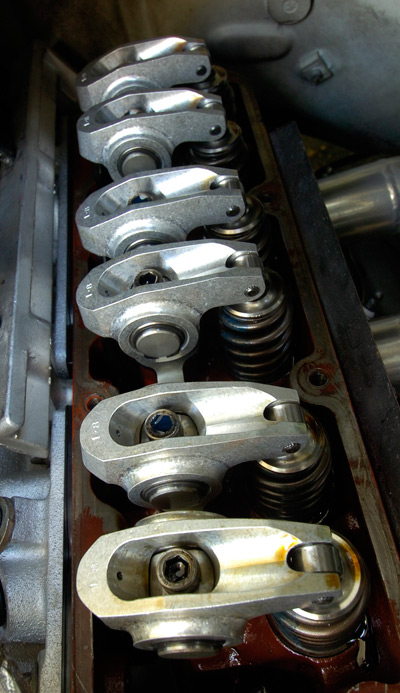

Next we

reinstalled the stock rocker arm fulcrum bars

and the stock roller rocker arms. Rather than

GM's torque-to-yield rocker bolts, we installed

INTENSE-Racing reusable bolts (PN HSH-RAB) and

tightened them to 25 ft/lbs. We stuck new Fel-Pro

gaskets in the valve covers and put them on.

The upper and

lower intake manifolds weren't ready for

installation, so we put the engine reassembly on

hold and turned to some chassis and brake mods. |

|

|

|

611.06) We decided to

break-in our modified V6 using the

stock, 1.6:1 roller rocker arms. Image:

CHpg Staff. |

|

|

|

|

We're ready to install

the intake manifolds and the rest of the

upper engine dress. Some question our

decision to retain the engine's balance

shaft as that forces use of a single row

timing chain which is said by some to

not be durable with high tension

aftermarket valve springs. Nevertheless,

we chose to take the "risk" as the Roll

Master chain's supplier, INTENSE Racing,

insists it has adequate

reliability/durability for our

application and we'd rather not have the

engine shake at idle a no-balance-shaft

engine exhibits. Image: CHpg. |

Drivetrain Digest

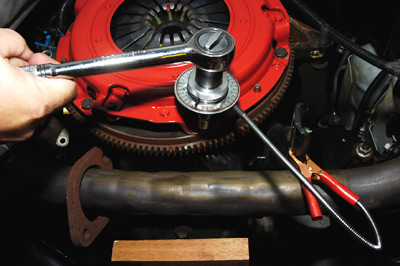

Our eventual goal is

250-hp on the motor and, if we do nitrous, 300+.

Planning for that, we needed a clutch upgrade so we

called McLeod Industries' Billy Mieczkowski. He said

that the stock clutch, a 9-11/16-in. unit of 1200-1400

pounds pressure, was inadequate for our needs. We

drained the TREMEC T5 five-speed, removed it per the

factory Service Manual, then pulled the stock clutch

assembly and headed for McLeod.

Inspecting our parts,

Mieczkowski advised that, while the clutch disc had

plenty of material left, its damper springs and their

mounts in the hub were worn, a common problem with

six-cylinder discs. The stock stuff was scrap so we

replaced it with a McLeod clutch (PN 360131) and disc (PN

260275). The McLeod has significantly more pressure,

1875 lbs., and its disc, with an enhanced-organic facing

and HD hub and damper springs, offers better reliability

and durability at our higher torque output and engine

speed.

|

|

|

Here's the clutch disc we took

out of the Tom Henry RS. While there was plenty of

facing left, the seats for the damper springs were worn

which the McLeod people tell us is normal for V6 discs.

Image: CHpg Staff. |

|

|

|

Replacing the O.E. clutch

hardware was this setup: a McLeod diaphragm clutch and a

McLeod organic-faced disc for street-high-performance

applications. Image: CHpg Staff. |

|

|

|

611.10) Before we put the disc in place,

we went over the flywheel's friction surface with a

Standard Abrasives Medium Surface Conditioning disc,

then wiped the surface with MEK. You'd be surprised how

often people attempt to put clutch discs in backwards.

This is how it should look, with the raised side of the

hub pointing to the back of the car. McLeod includes a

clutch pilot tool with every pressure plate. Image: CHpg

Staff. |

|

|

|

The clutch installation is

another of the many uses of our Mac Torque Angle Meter.

Image: CHpg Staff.

|

|

|

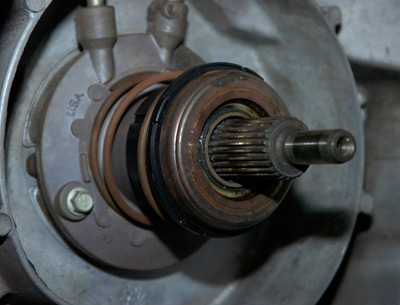

If your clutch release

assembly looks like this, replace it.

Image: CHpg Staff. |

The clutch release

bearing was worn. It's a GM-only part (PN 89060001) so

we ordered that and a pilot bushing (PN 24506531) from

Tom Henry Racing. We installed the new bearing on the

concentric clutch slave, changed the pilot, put the

trans back in then reinstalled the rest of the parts

removed to get the clutch out.

|

|

|

Red Line MTL is a synthetic,

GL-4-rated gear oil blended especially for manual

transmissions which require a low-viscosity lubricant

and are used in racing or high-performance street duty

cycles. Image: Red Line Oil. |

|

We filled the T5 with

Red Line MTL, a low-viscosity, 70W80,

ester-based-synthetic, GL4, gear lubricant. MTL provides

excellent protection and improved shift feel in manual

transmissions which require low-viscosity lubricants. It

has the appropriate coefficient of friction for

cone-type synchronizers whereas some gear oils, engine

oils, and ATFs are too slippery for proper synchro

function. MTL's wide viscosity range facilitates proper

shifting over the full temperature range a transmission

may experience. Its synthetic base stocks have a high

viscosity index which insures constant viscosity as

temperature changes. MTL is a 70W at low temperatures

and a high 80, nearly an 85, at high temperatures. That

range provides adequate viscosity to prevent wear and

deaden gear noise. MTL has outstanding shear stability

and oxidation stability, so its physical characteristics

will change little with use. |

|

|

|

While it looks like you tear the

whole interior apart to install the Hurst Shifter, the

center console is easy to remove and the shifter is held

with only four bolts. You can do the job in an hour and

the reduction in shift throw and improvement in shift

feel is well worth the effort. Image: CHpg Staff. |

Working our way back,

we added a Hurst Billet/Plus Shifter (PN 391-5032) which

has a shorter throw and feels more precise because it

eliminates the stock shifter's rubber coupler. Hurst's

user-selectable “bias springs” provide the tension you

feel when moving the shifter, cross-car, in the neutral

gate. The default is all four springs. While drag racers

like hefty centering tension, street-drivers and road

racers might not. If that’s the case, remove the inner

springs. Finally, we added the Hurst shift lever for a

T56 six-speed (PN 2388572) which accepts the O.E. shift

knob, giving the interior a stock appearance.

|

|

|

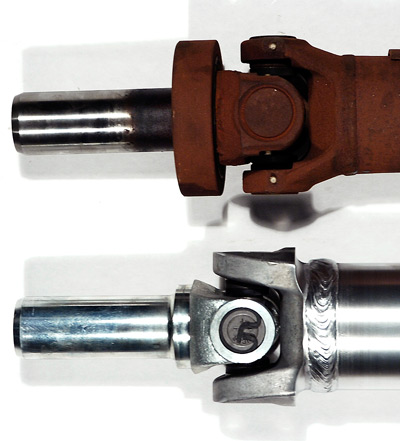

Inland Empire Driveline's

Manager, Jeff Gilroy, had our two driveshafts

side-by-side as he explained that, though less

high-speed vibration, less weight and better

acceleration, his company's product is a bolt-on,

win-win-win situation. Image: CHpg Staff.

|

|

The Tom Henry RS will

have a higher top speed because the engine is going to

have more top end and, after we installed Z-rated

Goodyear F1 GS-D3s in Part 1, we raised the speed

limiter to 118 mph and we may raise it again. This had

us wondering about the stock driveshaft. V6 shafts

become more prone to vibration at speeds beyond the

production speed limiter because of the interaction of

V6 firing impulses and the driveline's resonant

frequencies. To address this, GM sticks a fat vibration

damper on the driveshaft's front yoke. That's a cheap

solution but makes for a 20 lb. driveshaft and might not

be an effective fix, once top speed goes higher than

stock.

We had Inland Empire

Driveline Service build us a 41.5x3.0-in. driveshaft out

of .120 in. wall-thickness, 6061-T6 aluminum tubing and

forged 6061-T6 ends. Basically, this is an aftermarket

version of the unit used by Camaros with the 1LE option

but fitted with a V6 front yoke. Though it's larger, as

it's aluminum and lacks the big damper, there is a

whopping 50% weight reduction. At only 10 lbs, it has

far less rotating mass which not only eliminates

vibration at high speed but allows the car to accelerate

a little quicker.

|

|

|

|

The big (and heavy) difference

between the stock, steel driveshaft and the

high-performance, Inland shaft is the stocker's damper.

Image: CHpg Staff. |

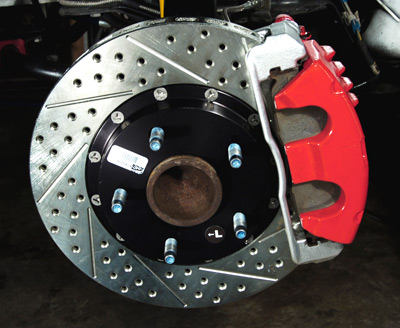

Better Stop

Stock brake pads on

later 4th Gen Camaros, the scary-expensive new units

from GM, are a great choice for hi-po street use, so we

kept them. If we start doing track days, we'll need a

more aggressive pad, but for now; stock is good.

Brake rotors are a

different story. They're a stunning example of how GM

cost cutting forces use of inferior materials. Stock

rotor durability, even for cars driven by people easy on

brakes, is lousy.

The problem is crappy,

low-silicon iron which lacks thermal stability causing

thickness variation to develop. Our O.E. rotors barely

made 40,000 miles before their thickness variation was

so great, the car shuddered upon every brake

application. The original pads had plenty of thickness

left, but the rotors were junk.

We pulled the caliper

assemblies, scrapped the GM rotors and replaced them

with Baer Brakes' EradiSpeed Plus parts (PN 2301006,

front, and PN 2302013, rear) which are more massive and

made of high-silicon iron. Additionally, the fronts are

a racing-derived, two-piece, reduced-weight design

consisting of an iron brake disc with a more efficient

cooling vent system bolted to an aluminum hat. For a

trendy look, EradiSpeed Pluses are drilled, slotted and

zinc-plated. These rotors eliminate brake shudder,

perform better, look cool and cost only about fifty

bucks more, per set, than O.E.

|

|

|

Brake performance and

durability improve with the Baer rotors

which are a bolt-on enhancement.

Performance is better because of the

more efficient cooling vane design.

Durability improves because of the

better quality cast iron Baer uses.

Image: CHpg Staff. |

|

|

|

The Baer Eradispeeds are both

drilled, slotted and zinc-plated. The drilling and

slotting is mostly cosmetic as modern technology in

brake pads has made the "outgassing problem" an urban

legend. The zinc-plating prevents rust on non-swept

areas of the rotor. The appearance of Eastwood's red,

caliper paint can't be beat. Image: CHpg Staff. |

Now that the THRS has

good-looking, drilled and slotted rotors, we needed to

tart-up the brake caliper assemblies a bit. Using

Standard Abrasives BriteRite Pads, we scrubbed them with

Simple Green and hot water then dried them with shop

air. Using Eastwood High Temp Coating (PN 10396Z), we

painted the mounting brackets silver and, using Brake

Caliper Coating (PN 12070Z), we painted the calipers

red.

|

Caliper painting takes

planning. Eastwood's polyurethane paint lasts about four

hours, once its reactant is added. In that four hours,

give all calipers two coats with at least an hour

between coats.

By the time we got

around to revising this part of the project for the

Internet version of the series, the brake caliper finish

was nearly two years old. Eastwood's product has proven

quite durable. When we wash or blow-off the brake dust,

those DIY-painted calipers still look great. |

|

|

|

On the back side of the brakes

was more performance hardware: our Aeroquip,

braided-stainless-steel covered Teflon brake hoses.

Their main advantage is an improvement in pedal feel due

the elimination of the slight expansion stock hoses

sustain during heavy brake applications. Image: CHpg

Staff. |

|

Our final brake upgrade

was braided-stainless-steel-covered, Teflon brake hose

assemblies. Building them with components from Eaton's

Aeroquip division, in front, we used 10". Aeroquip hoses

(PN FBPA0390-10) and, in the rear, between the calipers

and the ends of the hard lines on the rear axle, 8"

hoses (PN FBPA0390-8). Each has a straight, AN-3 fitting

on one end and a 90° on the other. To connect to the

calipers, we used long, 10-mm. banjo fittings (PN

FCM2947) in front and short 3/8" banjos (PN FCM2949) at

the rear, the O.E. banjo bolts and new copper washers.

To connect to the hard lines on the frame in front and

at the ends of the rear axle, we used Aeroquip AN-3 to

3/8-24 inverted-flare adapters (PN FCM2936). Aeroquip

doesn't make parts to connect the chassis' hard line to

the junction on the axle, so we had an 11" hose made by

Orme Brothers, a hose and fitting retailer in

Northridge, California. It has a 7/16-24 inverted flare

connection on one end and a T, which bolts to the axle

and accepts two 3/8-24 inverted flare fittings, on the

other.

GM used a mix of metric

and fractional inverted flared fittings on some 4th Gen.

Camaros. If you make braided brake hoses for these cars,

measure the fittings, first, before ordering parts.

Aeroquip makes a nifty "Port and Thread Identification

Kit" (PN FCM3644) for this purpose.

Motor Ready

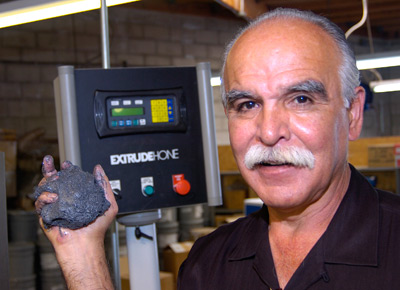

"Extrude Hone" is the

brand name for "abrasive flow machining" (AFM). Invented

50 years ago, during the Nike antiaircraft missile

program, it's widely used in the aerospace and

industrial fields. In the early '70s Southern

California's Melendez family formed Extrude Hone AFM,

Inc. and introduced the process to the automotive

industry. By the 1980s, its use became popular with

high-performance-street and racing engine builders.

Today, it's even used by OE's for limited production,

high-performance applications.

|

|

|

Ed Melendez, President of Extrude

Hone AFM, shows us a ball of the abrasive polymer used

to Extrude Hone the THRS's intake and exhaust manifolds.

Ed has the singular satisfaction being one of the

World's largest consumers of Silly Putty.

Image: CHpg

Staff.

|

This process removes

material from the interiors of intake manifolds and

other parts, leaving a smooth, polished surface behind.

AFM's active ingredient is silicon carbide particles

carried in a creamy polymer. The polymer is actually

Silly Putty and the Extrude Hone Corporation is the

world's largest manufacturer of the stuff and Extrude

Hone AFM is one of its biggest customers.

The abrasive polymer is

forced, or "extruded" through the part abrading and

polishing all surfaces exposed to it. The amount of

material removed depends on how long the part is

processed, the particle size and where in relation to

the point of polymer injection the abrading is taking

place. This modest enlarging and polishing improves flow

through the part.

|

|

|

The part to be honed is bolted to

a big nozzle assembly through which the Silly

Putty/silicone carbide mix is forced through the part.

Image: Willie Melendez. |

|

|

|

The silicone carbide removes

material from the inside of the manifold. Imagine this

as porting all interior surfaces of the manifold with

the amount of material removed being greater towards the

throttle body and lesser towards the port exits. Image:

Willie Melendez.

|

Typically, if you've

fitted your 3800 with a set of ported heads, the lower

intake manifold is "port-matched" using abrasive tools

and traditional porting techniques. Additionally, with

an induction system like that used on the 3800 Series

II, there is a performance gain in porting and polishing

the intake plenum, however, effectively doing that can

be challenging because of the difficulty in reaching

areas deep inside it.

Extrude Hone AFM

eliminates these troubles while doing a more uniform job

of removing material. it rounds all sharp edges and

polishes all surfaces. The process is done to the upper

and lower intake manifolds while they are assembled so

port matching of the two parts, as might be required

during the traditional porting process, is unnecessary.

|

|

|

After Extrude Honing, Ed

Melendez, himself, flow tested our upper intake

manifold. Image: Willie Melendez. |

The day we visited

Extrude Hone AFM to pick-up our intake and exhaust

manifolds, we requested a flow test and observed while

they did it. Tested on Extrude Hone's Super Flow SF600

Flowbench, air flow through the intake manifolds

increased by a whopping 25% and exhaust flow increased

an average of 13%.

You're asking, "What's

up with cast iron manifolds?" We'll switch to headers in

Part 4 of this series. For now, we want to try Extrude

Honed and coated stock manifolds to see if they can be a

budget-minded alternative to headers.

|

|

|

This is the data from the intake

flow test.

Image: Extrude Hone AFM.

|

|

|

This is the data from the exhaust

manifold flow test.

Image: Extrude Hone AFM. |

We installed the lower

intake manifold using a stock GM intake gasket set (PN

89017819) which we prefer because of the gaskets' metal

cores. During the lower intake manifold installation,

follow the Service Manual's instructions for tightening

the bolts and use of a thread locking compound is

required.

|

|

|

Proper tightness of the lower

intake manifold bolts is critical. Additionally, since

these bolts are tightened to a somewhat low torque, a

thread locker is required. Use of an inch-pound torque

wrench is advised. Image: CHpg Staff. |

Because the ports in

the two intake parts have been enlarged, the gasket

between them must be trimmed to enlarge its port

openings. We laid a Fel-Pro upper intake manifold gasket

(PN 95746) on a piece of plywood then used an Xacto

knife to enlarge its port openings by trimming the fiber

material right up to the RTV silicon sealing bead.

|

|

|

This is one of the time-consuming

tasks if your 3800 has an Extrude Honed or ported upper

and lower intake manifold. A sharp Xacto, a steady hand

and a slab of plywood are keys to good gasket

modification. Image: CHpg Staff. |

We had the upper intake

manifold powder-coated silver by Extreme Performance

Heat Coatings then installed it on the engine. Many of

the upper intake manifold fasteners are smaller than you

might expect. Tightening them requires an inch-pound

torque wrench. Observe service manual torque specs and

its tightening pattern.

|

|

|

Our Extrude Honed and Extreme

coated intake manifold goes on. Tightening the upper

manifold bolts is another critical process. To avoid

stripping threads or breaking bolts, use a torque

wrench. Image: CHpg Staff. |

Extreme Performance

Heat Coatings applied a silver metallic-ceramic coating

to the outside of the exhaust manifolds and a thermal

barrier coating to the inside. Extreme uses raw

materials from Techline Coatings, one of the top

suppliers in the performance coating business. As a

result, the manifolds look better, radiate less heat and

can be used without their stock heat shielding.

|

|

|

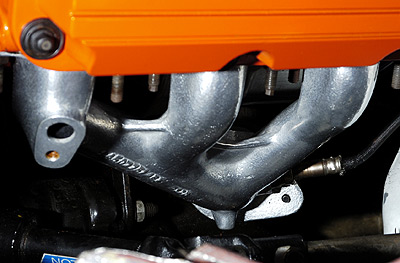

The Extrude Honed and Extreme

coated exhaust manifolds can be a low-cost alternative

to headers. One nice thing about them is they offer a

performance increase but, also, bolt up to the stock

downpipe assembly. Image: CHpg Staff.

|

Next, a final

beautification project: we painted the crankshaft

balancer, brackets, housings and some pulleys on the

front of the engine, the lower intake manifold and the

valve covers. For this we used Eastwood Co. products,

Extreme Chassis Black (PN 11175Z), Chevrolet Orange (PN

10016Z) and Stainless Steel High-Temperature Coating (PN

10364Z).

It Runs!

|

|

|

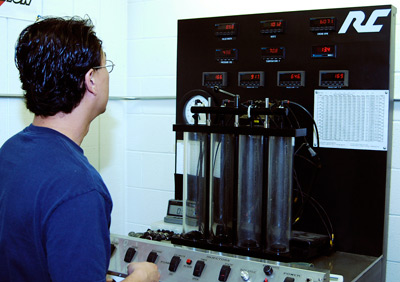

611.30) The first two steps in the

injector testing process at RC Engineering are 1)

ultrasonic cleaning (not shown) and flow testing, which

RC Engineering's John Park is doing here. Image: CHpg

Staff. |

We sent our fuel

injectors to RC Engineering cleaning and testing. In

tuning our mod'ed V6, we'll start with 19 lb/hr., stock

injectors but, if it needs more fuel than they can

provide; we'll step-up to RC's 21.5 lb/hr. units. After

RC's test, we stuck the injectors back in the fuel rail

and reinstalled it.

|

|

|

The third step is testing the

injector on a different test bench to analyze the

injector's flow pattern. Image: CHpg Staff.

|

We got the ignition

system up on the bench to install MSD Blaster Two-Tower

Coil Packs (PN 8224) for the GM "waste-spark",

distributorless ignition systems used on 3800s. The MSDs

put out up to 40kV which, when they're used in an

inductive ignition application like the THRS V6, is only

slightly more than the OE coils. Where the Blasters are

an advantage is during high-load operation at engine

speeds beyond where the stock coils normally operate.

Our project's engine is soon to get a rev limit higher

than stock and future mods, such as nitrous oxide

injection, will put a higher load on the ignition.

Better materials, such as higher-quality copper wire,

and more robust construction means the MSDs will be more

reliable when the combination of higher rpm and higher

ignition loads typical of a modified engine are present.

These coils, along with MSD Super Conductor plug wires

installed previously, give us a performance margin we

like.

|

|

|

Our ignition mods are: a set of

MSD coils, which are capable of higher spark output, and

a set of MSD Superconductor plug wires. Image: CHpg

Staff. |

|

|

|

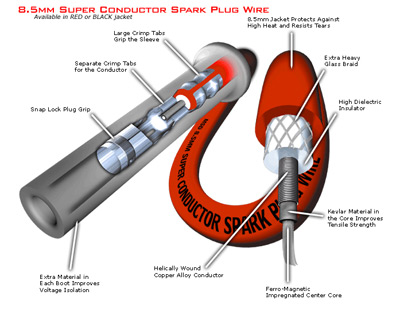

Image: MSD Ignition ( Click Image for

Larger View )

|

|

|

|

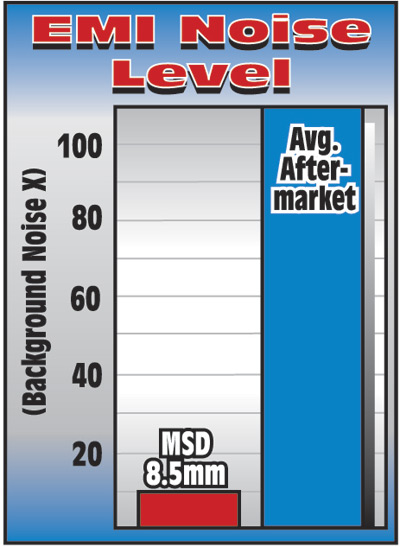

Superconductor 8.5-mm spark plug

wire was originally devised for use on racing engines in

cars with 2-way radios. It has a low resistance per unit

length--typically 50 ohms per foot--but a high level of

ignition noise suppression.

Image: MSD Ignition. |

We installed a fresh

set of Denso Iridium Power IT20 spark plugs. We've used

the IT-20 since the beginning of the Camaro

Performers magazine version of this project in 2005

and always have had good results. It is a heat range

colder than stock and its iridium tip is more durable

but has less resistance than platinum. Its small, 0.4-mm

center electrode and tapered ground electrode give the

spark maximum exposure to the incoming, air-fuel charge.

In short, we think the IT-20 is the best spark plug

choice for 3800s in street high-performance and mild

racing applications.

|

|

|

611.38) A Denso Iridium Power IT20 as

used in the Tom Henry RS engine. The main attraction of

the Denso is low resistance, from the use of Iridium in

the center electrode, high suppression and the cut-back,

V-shaped side electrode. Image: CHpg Staff. |

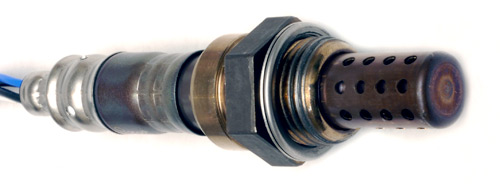

Oxygen sensors are

critical to drivability. We replaced the Camaro's, O.E.

sensors with Densos (PN 234-418, front, 234-4087, rear).

The Denso "O2S" is better because its aluminum-oxide

"trap layer" covers the sensor element and resists

damage to its platinum electrode and a porous, PTFE

(Teflon) filter on the sensor's atmospheric side

prevents moisture or contaminants from degrading

accuracy.

|

|

|

The stock Delphi oxygen sensor

used in 2001 V6 Camaro and, below, the better choice--a

Denso O2S. Image: CHpg Staff. |

|

|

|

This is a four-wire Denso

oxygen sensor for a '97-'02 3800 (PN 234-4018). We use a Denso

on any O2S replacement as we think it's better than the

Bosch or Delphi units. Today, Denso O2Ses are stock on

some but not all GM vehicles. Image: CHpg Staff. |

|

|

|

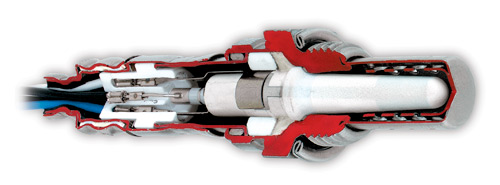

The same sensor cut open and painted-up

all nice. Its active component is the white, spear-like

element which is made of zirconia and has a

thin layer of platinum inside and outside. The inside is

open to the atmosphere and the outside is exposed to

exhaust flow. The difference between atmospheric oxygen

content (constant 21%) and exhaust oxygen content

(varies from zero to about 2%) generates a voltage which

varies from 100 to 950 millivolts. Image: Denso Sales

of California, Inc.

|

Finally, we reconnected

the exhaust, coolant plumbing and wiring. To reduce the

air bubble in the cooling system until the thermostat

opens, with the 'stat out and the water outlet off, we

filled the engine with a gallon of Dexcool antifreeze, a

bottle of Red Line Water Wetter and distilled water. We

reinstalled our Stant, 180° 'stat. A 160 was tempting,

but running that cool sets code P0182 for excessive

coolant warm-up time. Custom reprogramming can fix that

and we'll do that later, then try the 160.

We double-checked

everything, then lit the motor. For a few seconds,

lifters clattered, then the engine settled to a somewhat

less-noisy, but unstable idle. We connected our Bosch

Mastertech scan tester to read engine data. While idle

speed fluctuated, the engine was not stalling, no codes

set nor were idle air control (IAC) counts or fuel trims

way out of line. We used Mastertech's IAC function to

temporarily raise idle to 1000 rpm and the engine

smoothed-out. Once the thermostat opened, we opened the

cooling system bleeder until we saw coolant, then

topped-off and capped the radiator. We shut the engine

off and checked for leaks.

A drive around the

neighborhood showed that, while we lacked idle stability

below 1000 rpm, at light-to-medium load, the car ran ok

to our temporary, 4000 rpm rev limit. On a longer,

weekend test drive, not only did we have a funky idle

but we also observed knock retard ("KR"). We weren't

sure if this was "false" knock retard, due to valve

train noise, or real detonation, resulting from a

whacked-out fuel map too lean for our camshaft/cylinder

head package.

After changing the oil

filter, we did another 300 miles of easy driving to 1)

break-in the new parts and 2) do additional Mastertech

data logging to learn more about KR.

Cal Challenges

In Part 1, we used a

Hypertech Power Programmer for minor changes in the

engine computer calibration, however, the more

aggressive Comp Cam, bigger Manley Valves, better

flowing DeGroff heads and Extrude Honed manifolds we've

added pose a challenge the Hypertech was never designed

to address. No way could we continue to use it.

While there are a

number of aftermarket tuners having experience with 3800

Series II calibrations for racing and

non-emissions-legal, street applications, the

aftermarket has done little with "cals" for seriously-mod'ed,

street-legal V6es, so we knew a calibration which

exhibited good drivability, exhaust emissions compliance

in California and other states with stringent emissions

tests as well as a performance increase would be a

challenge.

|

|

|

Z-Industries' Ron Zimmer (right)

and a Camaro Homepage staff member discuss the initial

reprogramming of the THRS engine controller. Image: CHpg

Staff. |

We retained,

Z-Industries of Temecula, California, a top aftermarket

cal specialist. Z-I's owner, Ron Zimmer, told us that

the computer for the later V6s has programming as

complex as that of GM's latest stuff for the C6 Vette.

The cal for our project was a arduous task, even for a

pro like Zimmer.

On our first visit,

Z-Industries made progress on idle quality, worked on

knock retard strategy, revised wide-open throttle fuel

and spark function, changed the fans-on temp to 185°F

and reset the rev limiter to 6200 rpm. This took several

reflashes of THRS's ECM followed by road tests with

Zimmer riding shotgun, watching ECM data on his Bosch

TECH2 scan tester.

|

|

|

Z-Industries uses a Bosch

Diagnostics TECH2 scan tester to transfer the modified

computer program to the car's ECM. Image: CHpg Staff. |

While putting more fuel

to the engine had us using our mods to near their full

potential; we still had knock retard. Our Mastertech now

showed some "KR" under load, typical of detonation

rather than "false knock". We added five gallons of

Rockett Brand 100-oct. unleaded racing gasoline, road

tested and saw less knock retard, but it still wasn't

eliminated.

Since Part 1, Green

Filter revised its Camaro air filter (PN 2021) with

"custom fit tabs" on its edges. "Going Green" is a good

thing, so we dropped an updated filter in the air box

base. We added a Whisper Motorsports, carbon fiber air

box lid (PN CFLid-6-99/02) which eliminates the baffles

and fins inside the stock lid. The Whisper Lid replaces

the silly, plastic intake resonator, attaches the stock

rear air duct and relocates the intake air temperature (IAT)

sensor. By using carbon fiber in this Lid, Whisper

Motorsports stiffens the assembly, reduces it weight and

vastly improves the appearance of the underhood. Plus,

the Whisper Motorsports air box works well on a modified

V6.

|

|

|

The three air box lids we tested.

Top right is the stocker. Top left is an SLP V8 air box

lid which works with a V6 if the air ducts are

substantially modified. A problem with our SLP lid is it

tended to warp. Once it does, it leaks air. The best

choice in V6 air box lids is the Whisper Motorsports

unit (bottom) CHpg Staff.

|

|

|

|

The Whisper lid accepts a stock-sized air

filter element, either an O.E. filter or

our Green Filter and it clamps to the stock air box

assembly. It, also, accepts the stock rear air duct and

the stock IAT sensor. Image: CHpg Staff. |

Back at Z-Industries, a

week later, we had Zimmer back-off the spark a scosche

and add a bit more fuel. He, also, spent several hours

tweaking idle programming. When we left his shop, idle

stability was improved and the best we could expect

considering our cam profile. We decided we were,

finally, ready for Westech's Super Flow SF840 chassis

dyno.

What Kind of Power Does

it Make?

|

|

|

Finally...the Tom Henry RS back

on Westech's Superflow WynDyn chassis dyno.

|

|

|

|

Rockett Racing Fuel's Tim Wusz

adds some of his fine 100-octane unleaded Racing

Gasoline to the project car. Typically, we bump the

octane to 95.5-96 for chassis dyno testing where we are

adjusting spark calibration. Image: CHpg Staff. |

Several days later,

Rockett Brand Racing Fuel's, Tim Wusz, Ron Zimmer and we

reconvened at Westech. Dyno Technician, Ernie Mena

strapped our car to the Super Flow and made two baseline

passes. Darn knock retard was present under load, so Tim

Wusz supplied some more of his fine 100-oct. unleaded

for us to mix with the 91-oct. pump gas already in the

tank, then Ernie made several more passes during which

Ron Zimmer tweaked the fuel and spark tables. This put

our air-fuel ratio at WOT at an ideal 12.8:1 and further

improved idle stability, however, we still had a slight

KR issue. Nevertheless, we signaled Ernie that we were

done fooling with the cal (for now) and to go for the

money shot.

|

|

|

Ron Zimmer at work on our

calibration. Image: CHpg Staff. |

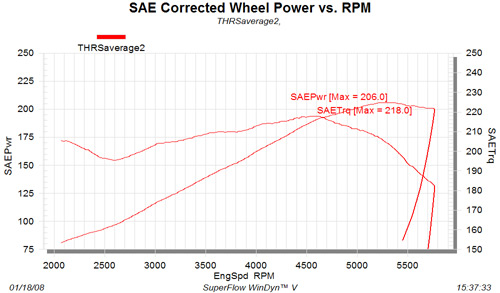

Bottom line: we're

making progress with the Tom Henry RS. Eight passes at

Westech averaged, at the wheels, 206.0 horsepower

(SAE-corrected) at 5350 rpm and 218.0 pound/feet torque

at 4600 rpm. That equates to about 250 hp SAE net at the

flywheel or around a 25% improvement over stock. Since

we are already at the 250-hp goal set back in Part 1 and

we've got plenty of tuning to do and a few more

modifications, we're raising our power goal to 270-hp.

Now that's what we're talkin' about!

|

|

|

While, right now, we're happy

with 206-hp at the wheels, if you look at the early part

of the torque curve, clearly, there's work to be done.

The engine is weak in the low-mid-range, actually

loosing torque between 2000 and 3500 rpm. Also, the

curve is a bit jagged, evidence of knock retard. Lastly,

we've yet to test the engine past about 5700 rpm. That's

all coming later in the series. Image: CHpg Staff. (

Click Image for Larger View )

|

When the THRS comes

back in Part Four of this series, hopefully, we'll have

the knock retard issue solved, turn-in some good

performances on straight pump gas and add some more

modifications.

Yella Terra Rocks

The first version of

this series, in Camaro Performers magazine back

in 2006, reused the SLP 1.8:1 rocker arms from Part One.

During preparation of the last part of the magazine

series, we found the SLP rockers were not compatible

with our Comp camshaft. The result was valve float above

5800 rpm and that was in-spite of SLP's Chief Engineer

at the time insisting the 1.8 rockers would work with

our cam.

|

|

|

At left is a Yella Terra roller

rocker arm for a 3800 Series II or, as they call it in

Australia, the "Ecotec V6". This particular unit is a

1.7:1. Note that it's smaller and lighter than the

3800's stock, investment cast steel, roller rockers.

Image: CHpg Staff. |

The solution was two

fold. First, as told in the last part of this series, we

replaced the Comp Cams valves springs we used at first

with springs (PN PSI-LS1511) having slightly more open

pressure which we sourced from Katech, Inc., the

Michigan firm which runs the engine program for GM

Racing's C6.R road race Corvettes.

Secondly, we installed

a different 1.8:1 rocker arm design which was lighter.

With a little investigation, we learned the manufacturer

of the SLP rocker was an Australian company called

"Yella Terra". Via email, we contacted Mark Conner,

Yella Terra's Technical Sales Manager, and explained our

problem to him. Conner responded quickly explaining that

the 1.8 SLP rocker was the company's first aftermarket

rocker design for the 3800. He, also, confirmed that it

had been intended for stock cams and was not compatible

with aggressive aftermarket profiles at higher rpm.

Conner went on to say

that Yella Terra had designed the SLP rocker several

years ago but had since discontinued that part. The SLP

1.8s were 16% lighter, per rocker, than the O.E., 1.6:1

stockers. Yella Terra has since further developed its

3800 Series II rockers by such that it was an additional

8% lighter yet had the same level of strength as the

first design. The new Yella Terra rocker is called

"Ultralite" and not only is its overall weight less, its

reciprocating mass is reduced even more by revising the

part's structure, especially at the valve end of the

arm. Mark Conner agreed to ship us two sets of the

Yella Terra second design rockers, 1.7s and 1.8s.

Because the Yella Terras have higher pushrod seats we

had to change pushrods so we ordered a set of 7.350"

Hi-Tech pushrods (PN 7950) from Comp.

|

|

|

We tested the Yella Terra 1.7s

for while and found they work ok with our Comp Cam and

the first set of valve springs we used, but we wanted

the slight power increase which comes from a 1.8:1

rocker. These are the Yella Terra 1.8 rockers we'll use

on the project car for the long-term along with Katech

valve springs. Image: CHpg Staff. |

Several weeks later,

when the Aussie rockers arrived, we put their support

bars on the heads, dropped in the longer Comp pushrods,

lubed the pushrod and valve stem tips with Red Line

Assembly lube, oiled each rocker with Red Line 10W30

then installed all those parts. We retorqued the rocker

bolts, then replaced the valve covers and other parts

removed to change the rockers.

In Part Four of the Tom

Henry RS project, we'll add headers, do some additional

tuning then run on the chassis dyno, again.

Baer Inc.

Suite 1201

3108 W. Thomas Road

Phoenix, Arizona 85017

602 233 1411

www.baer.com |

Bosch Diagnostics

2030 Alameda Padre

Serra

Santa Barbara CA 93103

800.321.4889

www.boschdiagnostics.net |

Cometic Gasket

8090 Auburn Road

Concord OH 44077

800.752.9850

www.cometic.com |

Comp Cams

3406 Democrat Road

Memphis, TN 38118

901.795.2400

www.compcams.com |

DeGroff's Cylinder Head

Service

18736 Parthenia #2

Northridge CA 91324

818.701.5274 |

Denso Sales of

California

3900 Via Oro Av.

Long Beach CA 90810

310.513.8582

www.densoaftermarket.com |

Eastwood Company

263 Shoemaker Rd.

Pottstown PA 19464

800.345.1178

www.eastwoodco.com |

Eaton Corporation

(Aeroquip)

1660 Indian Wood Circle

Maumee, Ohio 43537

419-887-9664

www.aeroquip.com/pages/performance.html |

Extreme Performance

Heat Coatings

515 N. Elevar St.

Oxnard CA 93010

805.485.2667

www.xtremeperformanceheatcoatings.com |

|

Extrude Hone AFM

8800 Somerset Bl.

Paramount CA 90723

562.531.2976 |

Federal Mogul

Corporation (Fel-Pro)

26555 Northwestern Highway

Southfield, Michigan 48034

248-354-7700

www.federal-mogul.com/aftermarket |

Goodyear Tire and

Rubber Co.

see your local Goodyear

dealer

www.goodyear.com |

Green Filter

Box 149

Mt. Braddock PA 15465

724.430.2050

www.greenfilterusa.com |

Hurst Shifters

9142 Independence Av

Chatsworth CA 91311

818.882.6422

www.hurst-shifters.com |

Inland Empire Driveline

Service

4035 E. Guasti Rd.

Ontario CA 91761

800.800.0109

www.iedls.com |

INTENSE Racing

8430 Estates Court

Plain City OH

43064-8015

614.207.2420

www.intense-racing.com |

Katech, Inc.

24324 Sorrentino Ct.

Clinton Twp MI 48035

586.791.4120

www.katechengines.com |

McLeod Industries

1600 Sierra Madre

Circle

Placentia, CA 92870

714-630-2764

www.mcleodind.com |

|

Orme Brothers

18453 Parthenia Pl.

Northridge CA 91325

818.885.1414

www.ormebrothers.com |

RC Engineering

20807 Higgins Court

Torrance CA 90501

310.320.2277

www.rceng.com |

Red Line Synthetic Oil

Corporation

6100 Egret Court

Benicia CA 94510

800.624.7958

www.redlineoil.com |

Rockett Brand Racing

Fuel

3703 W. Lake Avenue,

Suite 75

Glenview IL 60026

800.345.0076

www.rockettbrand.com |

Rockauto

rockauto.com |

Tom Henry Racing

Box 68

Bakerstown PA 15007

877.842.4389

www.tomhenryracing.com |

|

Whisper Motorsports

Suite 305

4400 118th Av. North

Clearwater FL 33762

727.573.1292

www.whispermotorsports.com |

Yella Terra USA

1935 Tommy Webb Drive

Meridian MS 39307

601 485-3355

www.yellaterra.com.au |

Z-Industries

31200 Santiago Rd.

Temecula CA 92592

951.303.6857

www.z-industries.com |

|