|

Building the Tom Henry RS

Part 5,

Page

3

Road

Test

With

the Eibach/Global West spring combo, QA1 Shocks,

upgraded Track Bar and SFCs in place, it was time to

road test and we started with some miles on city streets

and urban/suburban freeways. First thing we noticed? The

shock settings of 4-clicks, compression, 6-clicks,

rebound proved a good compromise between control and

comfort for around town driving.

|

|

Road test fun! After our suspension

upgrade we ran the car over California's famed Angeles

Forest Highway. The car's lateral grip is substantial.

Its behavior at the limit is predictable and easy to

control. Could we lower the car a little more and

increase roll stiffness a bit? Perhaps, but this car is

street-driven every day on California's crumbling, urban

and suburban roads. We think a little more suspension

travel is a good thing for that usage. Image: Gary

Peterson.

|

Next, we headed for some twisty, back-country roads to

really beat on this car. We didn't drive very far before

confirming that at the rear, the constant-rate springs

and double-adjustable shocks provided more consistent

suspension action and excellent damping. Because the

upgraded track bar was now height-adjustable, we could

adjust it a little lower than stock, providing even

better bite off corners or in drag-strip-style, standing

starts.

|

|

|

Where the Tom Henry RS's revised suspension

really shines is powering out of turns. The Global West

constant rate springs, TrackLink system and Track Bar

Upgrade allow the driver to get on the power hard and

early on corner exits.

Image: CHpg Staff. |

Expectedly, the Tom Henry RS is just a blast to drive

really hard. The car has a hell of a lot of lateral

grip. Plenty of roll stiffness, our front alignment

settings and the 265/40ZR17 Goodyear F1 Supercars (set

at 30-psi cold) on 17x9.5-in. Fikse Profil 5S wheels we

installed for Part Four make this car stick. The QA1s,

set at front, 6C7R and, rear, 5C7R, gave us outstanding

wheel control in aggressive driving, but might be a bit

harsh for daily-driver use. For race track use on

smoother surfaces, you'd probably want even more damping

and that's available from the QA1s by simply turning

their adjuster knobs.

The

THRS is generally neutral steering, but with little bit

of drop-throttle oversteer which can be used to control

yaw angle. Off the turns, as you roll on the throttle,

the car now really hooks. There's little doubt, the

Global West TrackLink and Track Bar systems enable the

4G F-car rear suspension get the power down in a way

that the stock suspension could never achieve. That's

probably why many road racers and autocrossers who run

fourth gens, use Global West Suspension parts.

|

|

We also gave our rebuilt brakes and Baer pads a good workout. The new parts performed well.

Image: CHpg Staff.

|

Executive summary: our revised Tom Henry RS suspension

and brakes are freakin' awesome.

We Be Programmers

In Part 3 of the Tom Henry RS, we had aftermarket

calibration engineer, Ron Zimmer at Z-Industries

reprogram our Camaro's PCM and Ron’s son, Drew, worked

with us in Part 4. We have greatly appreciated the

Zimmers' help with the THRS, both this Internet version

and the shorter print version of this series which ran

in Camaro Performers but, for this fifth

part of the series, because we’re up for the challenge

of learning something new; we're moving our engine

controls calibration activities in-house.

From Summit Racing Equipment, we ordered a copy of

HPTuners “VCM Suite”, which includes “VCM Editor,” a

software application for creating aftermarket

calibrations for 1997 or later GM vehicles.

We picked

"HPT" because the guys at Z-Industries often used it

when working on our car and it’s

the leading software app for tuning. This software runs

on any PC using Windows XP or Windows 7 so I loaded it

onto my trusty Acer 5670 laptop.

|

|

|

With the suspension and brake work complete and

validated, it was onto PCM tuning. The key hardware

parts of HPTuners VCM Suite are the "interface", at

left, and the editing and scanning software which runs

on a laptop PC loaded with either Windows XP or Windows

7. Image: CHpg Staff. |

With

the deadlines we have at the Camaro Homepage, our

learning curve for VCM Suite was pretty steep. There are

a several avenues by which one can learn to calibrate.

Find an experienced professional tuner who give you an

“internship"–great

idea but a rare opportunity. Search the Internet and

hang out on the numerous forums devoted to tuning–good

idea in theory, but in practice it’s

difficult to determine if what you’re

reading was posted by one of the many

“faux

experts”

who inhabit forums or by one of occasional, true

Internet tuning authorities who dispenses free

information. You can guess your way through using

“trial-and-error”

methods–probably

a bad idea. You can read some of the books on tuning

late model cars or, you can take classes on tuning. I

decided on a mix of the last two.

First, I

studied Greg Banish’s books, Designing and Tuning

High-Performance Fuel Injection Systems and

Engine Management: Advanced Tuning along with

Dyno Testing and Tuning by Harold Bettes and Bill

Hancock, all three published by CarTech Books. Then, I

went to school–I ordered a home-study class offered by

the “Tuning School” of Odessa, Florida in its “Tuning

the Right Way” series: A Beginner’s Guide to Tuning GM

Vehicles with HP Tuners Software.

I

found the Tuning School's curriculum indispensable in

our situation: needing to learn tuning basics in a short

amount of time. The class covers proven methods for

tuning a 1997 or later GM vehicle’s

PCM with HP Tuners. While the most of the material is

oriented towards students working with the Gen 3 or 4

V8s in late-‘90s

or later cars and light trucks, most of key techniques

you'll learn in the Beginner's class also apply to

writing calibrations for the 3800 Series 2 V6 in

’98-’02

Camaros.

|

|

Newbie tuner at work. In our first attempts at

calibration work, we had the Tuning School's textbook

perched on the steering wheel and the Acer on the

passenger seat. Image: CHpg Staff.

|

A

week's worth of nighttime reading had me through the

Tuning School’s

beginner’s

text book. After that, I was out in the shop, sitting in

the car with my laptop on the passenger seat and the

book rested on the steering wheel, going over some of

the procedures in the text and learning VCM Scanner and,

finally, how to download the ECM's existing calibration

to my laptop. A week later, after some more study and

several hours working with VCM Editor, I was ready to

reflash the ECM in the THRS with my first calibration.

There's no way we could have gone from HPT newbies to

writing calibrations in two weeks without the Tuning

School’s

home study courses. No doubt, we still have more to

learn, but we were on the right track.

At first, we lacked a wideband oxygen

sensor–a requirement for any cal work involving power

enrichment (PE). While we shopped for one of those, we

started using what we learned from the Tuning School to

improve our 3800's part-throttledrivability by getting

its part-throttle, long-term fuel trim values closer to

zero.

When an engine control system

operates in closed loop, it's always “trimming” the fuel

delivery commanded by the look-up tables in the

calibration by the amount necessary to have the air:fuel

ratio (AFR) as close to “stoichiometric” combustion as

possible. A stoichiometric AFR results in the least

exhaust emissions and good fuel economy. With "straight"

gasoline, depending on its blend, stoichiometric

combustion occurs when the AFR is somewhere between 14.5

and 14.7:1. If it's the oxygenated gasoline required in

many parts of the country, it can have up to 10% ethanol

blended with the gas but usually the ethanol component

is 6-8%. We tested a sample of the Valero Premium gas we

usually put in the Tom Henry RS and it was about 7%

ethanol. We've read posts on various Internet forums by

folks who've tested their fuel and 7% is common. Mix 7%

ethanol (stoichiometric at 9:1) with gasoline (stoichiometric

at 14.64) and you get a 14.25:1 stoichiometric air: fuel

ratio.

In the calibration we were using, the

value for stoichiometric AFR was 14.57:1 and had never

been changed. That number is the stiochiometric AFR for

a special type of gasoline, known as "indolene clear,"

which car companies use when developing engine controls

calibrations or doing fuel economy testing. Since the

Tom Henry RS always runs on oxygenated gas, we reset the

base air:fuel ratio for the system to 14.25:1.

Why did we do this? Well–the engine

controls use the "stoich AFR" value in their calibration

as the "standard" to which to trim fuel delivery. If the

value set in the calibration is not the same as the

actual stoichiometric air:fuel ratio of the gasoline

being used, some of the ECM's fuel trimming ability will

always go trimming for the difference between the stoich

value in the cal and the actual stoichiometric AFR of

the gasoline. That can be half-a-point in air:fuel, or

more, that the ECM will always correct before it can

trim fuel delivery for any other reason.

If the AFR is exactly stoichiometric,

the long-term fuel trim (LTFT) values are zero. If the

AFR is more lean than that, the LTFTs will be positive,

ie: the system adds fuel to the base fuel schedule. If

the AFR is rich, LTFT numbers will be negative, ie: the

system subtracts fuel.

Our V6 is modified to the point that

its part throttle fuel needs were quite a bit different

than stock. Consequently, the system was trimming the

stock calibration’s fuel delivery schedule quite a bit

to maintain stoichiometric AFR. As the ECM moves between

cells of the cal’s “main VE" table, if long term fuel

trim (LTFT) has to move more than 5-7 counts from one

cell to the next, it may have to skew the fuel trim

quite a bit. That is: if most cells require -3 to +3

LTFT, that spread is more advantageous than if some

cells require -8 and other, adjacent cells need +10. The

more often the system has to move through a wide range

of less-then-ideal trim values to get to the proper

figure, the more drivability and response can be

compromised.

The Tuning School's book, MAF and VE

Tuning taught us how to use VCM Editor and VCM Scanner

to evaluate the existing part throttle calibration then

alter that to produce a new part throttle cal which

decreased the range through which long-term fuel trim

skewed as the ECM moved from cell to cell of the

calibration's main VE table. The result was improved

drivability. Since we were working with AFRs at or near

stoichiometric, where a narrow-band sensor has highest

resolution, we were able to use data from the engine's

stock O2 sensors.

The

Tuning School's book, MAF and VE Tuning taught us how to

use VCM Editor and VCM Scanner to evaluate the existing

part throttle calibration then alter that to produce a

new part throttle cal which decreased the range through

which long-term fuel trim skewed as the ECM moved from

cell to cell of the calibration's main VE table. The

result was improved drivability.

|

|

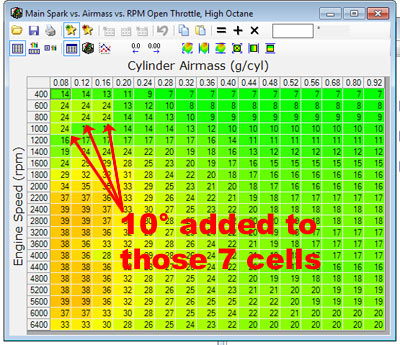

This screen shot shows the main, high-octane

spark table after we changed the spark timing at idle to

improve idle smoothness. Image: CHpg Staff. |

Another drivability issue we learned how to use HPTuners

to solve was idle stability and throttle response. A

couple of years ago, when the initial calibration work

was done for Part 3, a problem we could not fix was idle

speed surge.

We

knew from data taken using our Bosch Mastertech scan

tester and, of late, HPTuners VCM Scanner, that idle

spark timing was fluctuating between 3°

and 6°

BTDC. We believe this variation was a function of our

camshaft profile. This variation in idle spark timing

caused idle speed to surge. Plus, the retarded spark was

making the engine lazy just off idle.

When

we looked at the main spark tables with VCM Editor, in

the idle cells, the timing was a lot more than what we

were seeing when we took road test data with the

Mastertech or VCM Scanner. We suspected there were other

look-up tables which modify the base timing table at

idle but access to them is not supported by VCM Editor.

An email exchange with HPTuners Tech Support confirmed

that. They, also, told us that a future version of the

app will include support for those tables.

While there are some ways to access those idle spark

tables if you have your calibration in a binary (.bin)

file rather than in the HPTuners format and you acquire

some additional tuning software which can manipulate

.bin files, it was easier for us stick with HPT and

“fool”

the ECM into advancing the spark at idle by adding 10°

to the main spark tables in the cells where the engine

is idling. Doing that did not eliminate the hunting but

it reduced it significantly and vastly improved throttle

response just off idle. The engine's throttle response

went from "reasonable" to downright snappy.

Back

on the Dyno

At

this point, with a wideband not yet in our hands, we

wanted to do some WOT calibrating. We had a chassis dyno

session scheduled at Westech to test our recent exhaust

upgrades, so we decided to use the wide-band O2S which

is part of Westech's Superflow Autodyn dynamometer

installation.

|

|

At Westech, dynamometer technician, Ernie Mena,

using the Superflow Autodyn's control module, sets-up

for a chassis dyno run. Image: CHpg Staff. |

First thing we

did was add enough Rockett Brand 100-oct.

unleaded racing gasoline to bring the octane of

the fuel in the tank up to about 95.5. Whenever

we're going to do any testing where we change

the fuel or spark spark calibrations, we start

with about 95-oct, to keep the engine out of

detonation. Once we have the fuel and spark to

where we think we like it, we'll validate with

91-oct and see how much, if any, knock retard

results. Next, we ran three passes to validate

the larger S-pipe and new cat. Finally, we

worked on the engine's WOT performance because,

previously, we had trouble with air:fuel ratio (AFR)

being too rich.

With HPT's VCM Editor,

looking at the "Power Enrich vs. ECT" table, we

could see the existing cal was commanding as low

as 11.2:1 AFR during PE. While that's quite rich

for gasoline–rich even when 7% ethanol is

blended in the gas–it's common with stock

calibrations. We changed that to 12.15:1, a

better choice for max power on 7% ethanol, then

had Westech’s Ernie Mena run another pass. The

rich condition was improved, but still not

right. The problem seemed time-related, ie: AFR

was ok for several seconds into a dyno run, then

it would still go rich and became inconsistent

at high RPM.

We discovered part of the

problem was the "Power Enrich Fuel Adder RPM vs.

Time" table. Once the system is in power

enrichment for a certain length of time, this

table adds additional fuel for cat overtemp

protection or as a detonation hedge. We decided

to disable this function below 20-seconds (about

the length of a fourth-gear chassis dyno run)

then reduce its effects by 50% during longer

periods of WOT operation. With that cal written

to the ECM, we had Ernie Mena make three more

runs on Westech’s AutoDyn. The AFR at WOT was

now in the 12.1-12.4 range which was better, but

still not consistent enough.

|

|

|

We had Mena run a series of dyno passes at

Westech to try out some revised ECM calibrations. Image:

CHpg Staff. |

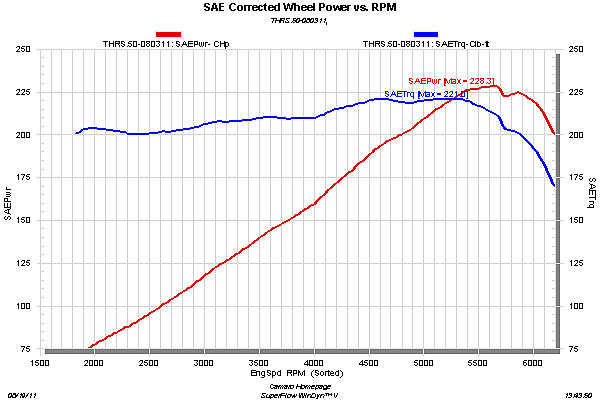

In spite of the AFR weirdness in PE,

in that final chassis dyno session for Part 5, we made

our best SAE-corrected, rear-wheel, peak power and

torque numbers yet:

228.3-hp@5660-rpm and 221.0 lbs/ft@4630-rpm. Using a

.82 correction factor, that works out to about 278-hp

and 270 lbs/ft SAE at the flywheel. The dyno data, also,

explains why the Tom Henry RS is such fun to drive. The

torque curve is flat as the proverbial pancake–between

200 and 225 lbs/ft rear wheel torque from 1800-5900 rpm.

|

|

Dyno results from the best run of the bunch.

We're not sure what caused the little dip just past peak

power but, in Part Six, of the THRS series will try to

find out. Image: CHpg Staff. |

On

the dyno, using

“VCM

Scanner”,

we learned that at WOT and high rpm, the PCM was

commanding very high injector duty cycles. Running the

injectors for sustained periods at high duty cycle is

not recommended.

When

we looked into installing new injectors with higher flow

capacity, John Park at RC Engineering, the leading

supplier of high-performance electronic fuel injectors

in the aftermarket, told us if the sustained duty cycle

is 85-100%, the engine may have inconsistent air-fuel

ratio because the injectors are difficult to control

consistently when they are near full-open. RC

Engineering and other experienced tuners suggest

"larger" injectors when the sustained duty cycle is

greater than 85%. In Part Six of the THRS series, we'll

address that issue. We’ll,

also, have more on using HPTuners to further tweak our

ECM calibration. We'll work on that dip in the torque

curve just past peak power.

|

|

Did our cal changes effect emissions? Nope.

Right after the dyno test, the car passed the

California Enhanced Smog Check. This time, for

hydrocarbons (HC), carbon monoxide (CO) and carbon

dioxide (CO2), the car was actually cleaner than it was

three months before, when we ran it through the Smog

Check prior to registration renewal. Oxides of Nitrogen

(NOx) increased slightly, but were still under the

limit. Image: CHpg Staff. |

The

final engine-related activity for this part of the THRS

series was to take the car to Mike Garibay's Quality

Auto Service in Pomona, California for an exhaust

emissions test. Garibay rolled the car onto his special

chassis dyno used for the California Enhanced Smog Check

procedure.

Once

again, the Tom Henry RS passed the Smog Check

easily–continuing proof that the right mod package and

the right tuning can provide a significant performance

increase combined with low exhaust emissions.

One

interesting lesson we learned during the time leading up

to our emissions test at Quality Auto Service. We had

code P0128 set because of the slow warm-up discussed in

the section on cooling system mods. We cleared codes

with our Bosch Mastertech but, when that happens, all

the second generation on-board diagnostics (OBD2)

“readiness flags” are wiped out, too. Those flags set in

the ECM once it determines various tests of emissions

controls, such as EGR function and catalyst efficiency,

which are required by OBD2, are ready to run.

State

emissions tests which have the test technician

connecting his equipment to the car’s diagnostic link

connector (DLC) will usually fail the car, regardless of

its tailpipe emissions, if readiness flags are not set.

Many scan testers, including our Bosch Mastertech and

the Actron AutoScanner discussed earlier, can display

readiness flags so if you cleared codes shortly before

going for a smog check, look at the flags with a scanner

before you test to verify they are set.

After

codes are cleared, the flags eventually reset during

normal driving but it can days hours, days, even weeks

for them to do so. You can force the flags to set in a

shorter time if you drive the car according to a

specific “drive cycle” listed in the Factory Service

Manual. Typically, this takes less than an hour.

We did

that–several times, in fact–but found some tests

remained incomplete. After thinking about this for a

while and re-reading the information about DTC P0128 in

the FSM, we decided to take out our 180° thermostat and

replace it with the stock 192° unit.

And

Voila! One drive cycle and all the flags set. Some of

those readiness tests, specifically the EGR function and

the catalyst monitoring tests, won’t complete unless the

engine coolant temperature (ECT) is higher than 180°F.

After the flags were set, we reinstalled the 180°

thermostat, took the car for the smog check and passed

easily.

Braless No More

This

project car is ten years old and will be on the road for

a number of years. Because of that, we decided to put

paint protection film (PPF) on our Camaro's front end–something

we probably should have done much sooner.

Known to the car hobby as a

“clear

bra”,

polyurethane PPF, was developed by the 3M Company for

aerospace applications. In 1990, the Department of

Defense made

“3M

Scotchcal”

famous when, during Gulf War I, it discovered the film

significantly reduced dust and sand erosion of

helicopter rotor blades during take-offs and landings in

the desert.

In

the early '00s, 3M introduced Scotchcal to the

automotive aftermarket but rebranded it as

“Scotchgard”,

a name more familiar to consumers. This adhesive-backed,

polyurethane PPF is 0.8-mil thick and is applied to

parts of the car’s

exterior which are susceptible to abrasion and pitting

from sand, dirt and small stones.

Clear bras usually can’t

be installed by DIYs because of the difficulty in

working the product. A proper installation takes

training, experience and special equipment. 3M has a

nationwide network of factory-trained installers. After

some research, we found the best clear bra installer

near the THRS base of operations, was Transhine Auto

Detailing in Whittier, California.

Transhine's owner, Bill DeBever, has been in the auto

detailing business since 1981 and has been installing

clear bras on cars and trucks since the early

‘00s.

He told us that Scotchgard and 3M’s

other PPF, Ventureshield, along with competitors from

Avery, XPEL Technology and others, have similar price

points. DeBever says Scotchgard is the most durable,

however, it is, also, the most difficult to install.

DeBever recommended Scotchcal for cars like ours which

see high annual mileage.

When

we arrived at Transhine, Bill gave our Camaro the

once-over then announced that, because a clear bra must

be installed over a clean surface and that our car's

paint was in reasonably good condition, but its finish

was covered with contaminants and water spots; it would

be best to do Transhine's full

“Exterior

Polish and Wax Detail”.

We couldn't argue with the $165.00 price. It was a heck

of a deal considering how much work the THRS's exterior

needed.

|

|

Transhine's Bill DeBever at work, clay barring

the THRS. A secret of detailing is to clay bar the

exterior while it's still wet after rinsing. Image:

CHpg Staff. |

|

|

Once the car has been clay barred, then it's

rinsed a second time and dried. Image: CHpg Staff.

|

During the Exterior Detail, the entire body was

clay-barred during the water rinse stage of the car wash

process. Water spots were removed with a special

chemical which Transhine applies, lets stand for a short

period then wipes off. After that, the car was

re-rinsed, dried and moved to Transhine's PPF

installation bay to have the clear bra installed. We

were surprised how much

“whiter”

the car looked after being clay-barred and having the

water spotting removed.

|

|

The clear bra installation begins with

downloading a pattern from a pattern vendors and loading

that into a PC. The computer controls an automated

cutter which cuts the pattern into the film. Image: CHpg

Staff. |

The

sections of Scotchgard are cut from long rolls of film

by a computer-controlled machine. The pattern is in

software running on a PC and Transhine has patterns for

most cars and light trucks. A water-soluble lubricant is

sprayed on the front end bodywork and then the film is

laid in place. Once the film is positioned, the lube and

any air bubbles which develop are squeegeed away with

special rubber blades designed for applying PPF. The

tough part of a clear bra installation comes when

installing the film on body work having compound curves

or other complex shapes. A special "steamer" is used to

soften the film when its applied to parts of the body

having sharp corners.

|

|

Once the clear bra was in place, the car was

moved to Transhine's exterior detailing area where wax

was applied and buffed by Ryan Kreiss. Image: CHpg

Staff. |

|

|

|

|

Installing

ScotchGard PPF requires training, skill

and, in some situations, special tools,

such as a steamer. First the film is

wetted with a solution which allows

repositioning of the film once it's

applied. DeBever places it on the panel,

positions it, squeegees away bubbles and

pushes the edges in place. On a surface

with tight or compound curves, the

steamer is used to warm the film and

make it more pliable. Image: CHpg Staff. |

|

It

took Bill DeBever a couple of hours install a clear bra

and, after watching the installation, we can see why

training and experience are necessary. We were relieved

to have Transhine do the work and appreciated the

quality DeBever put into the installation. Once the

Scotchgard PPF was on the car, it was moved back to

Transhine's polish/wax area where the exterior detailing

was completed.

In

the next part of the Tom Henry RS project, we’ll

upgrade our V6’s

fuel injectors and install nitrous oxide injection. Stay

with us.

|

|

Image: CHpg Staff.

|

Sponsors

Apex

Tool Group

(Gear Wrench)

Suite A

14600 York Rd.

Sparks MD 21152

800.688.8949

www.gearwrench.com |

Autotronic Controls Corp. (MSD)

1490

Henry Brennan Dr.

El

Paso TX 79936

915.857.5200

www.msdignition.com |

Baer

Brake Systems

222

West Peoria Ave

Phoenix AZ 85029

602.233.1411

www.baer.com |

|

Big John's

Performance, Inc.

24233 Creekside Rd.

Valencia CA 91355

661-254-1611

www.bigjohnsperformance.com |

Bosch Diagnostics

2030

Alameda Padre Serra

Santa Barbara CA 93103-1716

800.321.4889

www.boschdiagnostics.net |

CarTech Books

39966 Grand Ave.

North Branch, MN 55056

800.551.4754

www.cartechbooks.com |

Denso Sales of California, Inc.

3900

Via Oro Av.

Long

Beach, CA 90810-1868

310.834.6352

www.densoaftermarket.com |

Design Engineering

604

Moore Rd.

Avon

Lake OH 44012-2315

800.264.9472

www.designengineering.com |

Eastwood Company

263

Shoemaker Rd.

Pottstown PA 19464

800.345.1178

www.eastwood.com |

|

Engine Pro Performance

4891

Independence Street, Suite 155

Wheat Ridge CO 80033

800.364.4631

www.enginepro.com |

Extreme Performance Heat Coatings

515

N. Elevar St.

Oxnard CA 93010

805.981.3888

www.xtremeperformanceheatcoatings.com |

Fel-Pro

26555 Southwestern Highway

Southfield MI 48033 |

Fikse Wheels

Suite 110

667

Sumas Way,

Abbotsford BC V2S 7P4

Canada

877.856.7311

www.fikse.com |

Flowmaster

Suite 125

100

Stony Pt. Rd

Santa Rosa CA 95401

800.544.4761

www.flowmastermufflers.com |

FLUIDYNE

202

Raceway Dr.

Moorseville NC 28117

888.358.4396

www.fluidyne.co |

|

Global West Suspension

655

S. Lincoln Av.

San

Bernardino CA 92408

877.470.2975

www.globalwest.net |

Goodyear Engineered Products

703

S Cleveland-Massillon Rd.

Fairlawn OH 44333

888.899.6354

www.goodyearep.com |

HP

Tuners, LLC

725

Hastings Ln

Buffalo Grove IL 60089

www.hptuners.com |

|

Katech

24324 Sorrentino Ct.

Clinton Twp MI 48035

866.528.3241

www.katechengines.com |

Kimberly-Clarke (Wypalls)

400

Holcomb Bridge Rd.

Roswell, GA 30076

800.241.3146

www.wypall.com |

Matco Tools

4403

Allen Road

Stow, Ohio 44224

866.288.8665

www.matcotools.com |

Motive Products

Unit

G

5750

Obata Wy

Gilroy CA 95020

408.846.8800

www.motiveproducts.com |

QA1

Motorsports

21730 Hanover Av.

Lakeville, MN 55044

800.721.7761

www.qa1.net |

Quality Auto Service

3460

Falcon St.

Pomona CA 91767

909.596.5502 |

RC

Engineering

20807 Higgins Ct.

Torrance CA 90501

310.320.2277

www.rceng.com

|

Red

Line Synthetic Oil Corporation

6100

Egret Court

Benicia CA 94510

800.624.7958

www.redlineoil.com |

RockAuto, LLC

6680

Odana Road

Madison WI 53719

866.762.5288

www.rockauto.com |

SPX

Corp. (Actron)

15825 Industrial Parkway

Cleveland OH 44135

800.228.7667

www.actron.com |

SPX

Kent-Moore

28635 Mound Rd.

Warren MI 48092-3499

800.578.2233

www.spxkentmoore.com |

Sunshine Makers (Simple Green)

15922 Pacific Coast Highway

Hunington Harbor CA 92649

800.228.0709

www.simplegreen.com |

Transhine Auto Detailing

15130 E. Whittier Bl.

Whittier CA 90603

562.693.5619

www.transhine.com |

The

Tuning School

Unit

A

2328

Destiny Way

Odessa, FL 33556

727.264.8875

www.thetuningschool.com |

Tom

Henry Racing

5886

Route 8

Bakerstown PA 15007

877.842.4389

www.tomhenryracing.com |

Valco Consumer Products

411

Circle Freeway Dr.

Cincinnati OH 45246

800.788.386

www.valco-cp.com |

Westech Performance Group

11098 Venture Av.

Mira

Loma CA 91752

951.685.4767

www.westechperformance.com |

Yella Terra USA

1935

Tommy Webb Dr.

Meridian MS 39307

601.485.3355

www.yellaterra.com.au |

|

Summit Racing

Equipment

800.230.3030

www.summitracing.com

|

Rockett Brand

Racing Fuels

Suite 75

3703 W. Lake Avenue

Glenview IL 60026

800-345-0076

www.rockettbrand.com |

|

Return

to Project Index Click Here

|