Building the Tom Henry RS

Part One: Easy Stuff First

Since

Camaro's 1967 debut, a six-cylinder engine ('67-'79,

I-6; '80-'02 and '10-up V6) has been either standard or,

for four years in the early-’80s when General Motors

made the awful mistake of an inline-four for a base

engine, a midlevel option.

For

the Camaro's first ten years, V8s outsold sixes by a

considerable margin, but in 1977, with our country in

the throes of an agonizing gasoline shortage, V6s sold

on par with V8s. From then on, until production

temporarily ceased after model year 2002 (MY02),

six-cylinder market penetration averaged 50.4% and, for

MY93-02, V6es sold 62.4%. Bottom line, there’s a ton of

sixes out there, especially in fourth generation Camaros

and that trend is sure to continue with the fifth

generation, 2010-up cars.

One

reason V6es sold well towards the end of the 4th Gen era

was the 200-hp, 3.8-liter engine introduced in halfway

through 1995. Called “3800 Series 2”, it’s the unblown

version of the supercharged motor used up to MY05 in the

Impala and Monte Carlo SSes. By mid-'90s standards, for

buyers looking for a sporty coupe but for whom

performance was a consideration but not the most

important one, this offered a more affordable

alternative to the V8-powered Z28s and SSes.

Back

in late-'05 and early-'06, when gas prices went bonkers,

visitors to our parent company, Tom Henry Racing (THR)

about V6es. Aftermarket companies tell us demand for V6

performance products has grown indicating interest in

hot-rodding those cars. There are even web sites devoted

to V6 Camaros at www.forum.camarov6.com and

www.3800pro.com/forum/.

|

|

Here's our project car.

It'll take us about year but it will

end-up as the Tom Henry RS and will use

a few general ideas we hope to see in

the '09 base Camaro. Image: CHpg staff. |

We

decided to jump on the bandwagon, acquire a 2001 Camaro

V6, 5-speed and try some mods. We're calling the car a

"Tom Henry RS", in honor of the famed V8-powered Tom

Henry SS "tuner" Camaros of '01 and '02. Since we're

starting this project in the dead of winter, we've

farmed the job out to THR's, West Coast development

"laboratory" near Los Angeles.

Our

goal is more exciting street performance, not building a

drag race car. In addition this project is a little bit

of "what-if". We want to modify the engine to about the

300-hp level to match the performance of a 2010 Camaro.

Additionally, we're going to modify the suspension of

this 4th Gen V6 and see what happens.

Our

engine mods will pass a state exhaust emissions test and

won't degrade low-end torque. Our suspension

enhancements will improve handling but will still have

the car riding reasonably nice enough for commuting over

the rough surfaces of freeway/expressway systems in

cities with the worst roads in the country, such as

Philadelphia, Detroit and Los Angeles.

Before

we start working, let's talk about service data because

information is power–power over your Camaro if you work

on it yourself. Unless you’re an experienced Camaro

technician, you need a factory service manual (FSM) from

Helm, Inc., publisher of GM all service data. Our

2001 Chevrolet Camaro Service Manual was

indispensable in preparing this series.

|

|

|

Information is power. The

best service information on any Camaro

comes in the factory service

manual--actually, in this case, three

manuals. Image: CHpg staff |

|

A downside of

the factory manual is cost. Some of the stuff we

are going to do to the Tom Henry RS is discussed

in the less-expensive,

1993-2002

Camaro Haynes Repair Manual.

While the Haynes omits some front suspension

information, suggests some questionable tool

choices, and erroneously states you can’t work

on the brakes without a scan tester; it's an

acceptable reference for those on a tight budget

doing regular maintenance or basic repairs. On

the other hand, if you're getting into engine

controls diagnosis or heavy mod'ing, buy the FSM. |

What

about parts? Most of the GM and aftermarket parts we're

going to use during the next 12-months or so can be

sourced from Tom Henry Racing, the performance parts

sales division of Tom Henry Chevrolet. In the case of

the few parts which can't be purchased from THR, we'll

tell you where to get them.

The

staff of Tom Henry Racing's parts operations, headed by

Parts Manager, Stan Lorence, stands ready to assist any

Camaro Homepage visitor in finding Camaro parts.

Additionally, the people at Tom Henry Racing's Service

Department, headed by Manager, Cory Henderson, can

install many of the modifications discussed in this

series.

First

Mods

After

wheels and tires, perhaps the most popular aftermarket

modification performed by Camaro fans is the addition of

an aftermarket exhaust system. Flowmaster’s American

Thunder system for ‘98-’02 Camaros with 3800 V6es (PN

17358) has larger, 2.5-in. aluminized pipe, an 80-series

muffler and stainless steel tips, all typical Flowmaster

features. It's unique part is a resonator,

cleverly-packaged beneath the passenger-side rear seat.

Flowmaster says that certain frequencies of V6 noise are

difficult to attenuate and this resonator facilitates

that. One Saturday, we got the car up on jack stands and

installed the American Thunder system using hand tools.

We demanded increased performance, improved sound and

better appearance. Flowmaster’s cat-back got us all

three.

|

|

|

When we tried to get the

stock exhaust off, we found the

slip-joint behind the cat rusted tight.

An overnight treatment with Sili-Kroil

aerosol, one of the best penetrants on

the market sold by Eastwood Company, and

some additional blasts with Sili-Kroil

as we beat the old exhaust off with a

hammer, finally brought success. It's

amazing the restriction in this area of

the system where there are four

reductions in pipe size. The Flowmaster

exhaust eliminates the final step.

Modifications we'll do later in the

project will eliminate the third step.

Image: CHpg staff. |

|

|

|

|

The Flowmaster exhaust for ’98-’02, V6s. Similar systems

are available for ’95-’97s 3.8s (PN 17357). It uses

stock exhaust hangers, comes with hardware and has

large, stainless steel tips. The sound is the seductive,

deep tone for which Flowmasters are famous. Image: CHpg

staff. |

|

|

Chassis dynamometer testing will be a key

part of this project series. All of our

chassis dyno work will be done by the

Westech Performance Group in Mira Loma,

California. Westech's owner, Rick Stoner is

a long time Chevrolet enthusiast and owns a

number of Chevy hot rods and classic

Corvettes. Westech's key specialties are

dynamometer testing, both engine and

chassis, and custom engine building.

Westech’s SuperFlow SF840 chassis

dynamometer is a state-of-art piece of

equipment which can be run in either the

"brake dyno" or "inertia dyno" modes. For

simple performance validation, Dynamometer

Test Technician Ernie Mena typically runs

the SF840 as an inertia dyno. |

|

|

|

This is

Ernie Mena setting-up a wide-band O2 sensor

prior to one of the many tests we ran at Westech

Performance Group in the process of modifying this car.

Westech uses a unique, vacuum assisted O2S sensor which

quickens the system's response. Image: CHpg staff. |

|

|

|

|

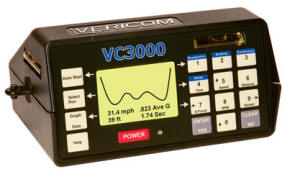

This is the Vericom VC3000 which replaced the veteran,

VC2000 a couple of years ago. It has typical Vericom

features: two-axis accelerometer core, 400Hz sampling

rate, and ability to upload data to a PC. New with the

3000 are: larger 128x64 LCD screen, ability to recall up

to 256 tests from memory, better keyboard, better

mounting system, USB port and–we saved the best for

last–with the DAQ model, ability to record OBD2 data via

the car's diagnostic link connector (DLC) as well as

from up to six accessory sensors. In our experience, the

Vericom VC3000's larger display and improved keyboard

make it nicer to use and the built in bubble levels are

a handy feature. Image: Vericom Computers. |

|

Westech's Superflow

showed our V6 with the Flowmaster American

Thunder exhaust system gained a hair over 11,

horsepower (SAE-corrected) at the rear wheels

and road test numbers backed that up. Using a

Vericom VC3000 Performance Computer, an on-board

vehicle dynamics tester, we saw 0-to-60 time

decrease from 7.83 to 7.44-sec. and quarter mile

stats going from 16.15-sec./89.14-mph to

15.87/90.69.

Eleven horsepower and

nearly two tenths and a mile-and-a-half an hour in the

quarter is an outstanding improvement for just an

exhaust change on a car which, in stock trim, made only

162-hp (SAE) at the wheels. Clearly, the O.E. exhaust is

restrictive. In addition, it was too quiet, sounded

funky and had ugly tail pipes. The American Thunder

system gives that deep-toned, trademark Flowmaster sound

and its stainless outlets look a lot better. The Aussies

at Holden, who are doing most of the vehicle development

of the 2010 Camaro, need to listen to our project car so

they won't make the same mistake made by GM on the 4th

Gen car and put a wimpy exhaust on V6es.

|

|

At Tom Henry Racing we put lubricants from the Red Line

Synthetic Oil Corporation in a lot of customers'

modified, street high-performance Chevrolets. From the

Cobalt SS Supercharged to the Impala SS and from the

Camaro to the Corvette Z06, just about any hot rod Chevy

can benefit from Red Line's premium synthetic products.

In this project car, we

used Red Line 10W30 Engine Oil, Red Line Power Steering

Fluid in the power rack-and-pinion steering system, a

50/50 mix of Red Line D4 ATF and Red Line MTL in the

car's TREMEC T-5, five-speed transmission and Red Line

Heavy Shockproof Gear Lubricant in the rear axle. The

gain was slight, 1.5hp (SAE) at the wheels, so the chief

advantage of Red Line products is their enhanced thermal

stability and the better durability of powertrain

components which comes from that. There’s also

the possibility of extended engine oil drain

intervals, if we choose. |

|

|

|

We began

our Red Line Synthetic conversion with

10W30 Engine Oil, and Power Steering

Fluid. Image: GHpg staff. |

|

|

|

|

Going

Green is easy. Pop open the filter

housing, remove the dirty, stock filter

and slip in the Green. Image: CHpg staff. |

|

We wanted an oiled

cotton air filter so we added a “Green Filter” (PN 2021)

we got from THR. While many filters have cotton media, a

Green uses two layers of woven cotton which are thinner,

stronger and hold filter oil better than the gauze used

by K&N and others. The Green Filter people say that,

because it’s woven, the thinner material still traps

particles as small as 5 microns. More interesting is

what they claim about filters with injection-molded

edges. During molding, rubber can leak onto the filter

which reduces its area. Since a Green’s edges aren’t

injection molded; that can’t happen. When we compared a

Green to an injection molded K&N Filter, sure enough; we

noticed that difference. |

|

|

|

The

stock, ACDelco 41-921 (top right) and the Denso

IT-20. They are different designs--the ACD plug is

platinum-tipped, the Denso uses an iridium tip and is,

also, a colder heat range, better suited to an engine

which runs hard. Image: CHpg staff. |

|

|

|

|

The Denso "Iridium Power"

IT-20 has a very small, Iridium center

electrode along with a cut-back and

tapered, ground electrode. Both these

features allow the air-fuel mix in the

combustion chamber increased exposure to

the spark. As a tip material, Iridium

has as good or better durability than

platinum, but lower resistance. That

lower resistance can make a more

powerful spark available at the plug.

Image: CHpg staff. |

|

Dyno

runs, quarter mile testing and aggressive street driving

made colder spark plugs desirable, so we installed Denso

IT-20 Iridium Power plugs which are sold by THR. The

IT-20 is one heat range colder and its iridium tip is

more durable but has less resistance than the stock

platinum, AC Delco plugs that were in the engine when we

started. The Densos' small, 0.4-mm center electrode and

tapered ground electrode give the spark maximum exposure

to the incoming, air-fuel charge. We should add that

even General Motors must see merit in the Denso spark

plug design because after about 2004, some Chevrolets

have Densos from the factory.

|

|

|

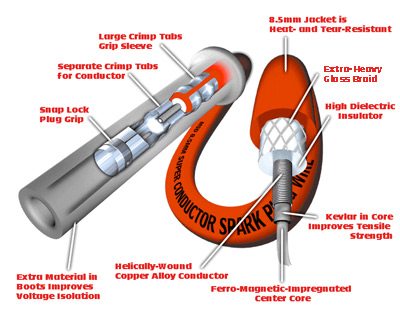

MSD Super Conductors are the same length as the stock

wires. The 8.5-mm. MSDs fit the stock wire looms. Red

wire and gray boots add a little color to an otherwise

colorless engine. Image: CHpg staff |

|

|

|

The

8.5mm Super Conductor Spark Plug Wire

has many design features intended to

meet the reliability/durability needs of

NASCAR NEXTEL Cup race engines. Image: Autotronic

Controls Corp |

|

|

We put MSD’s Super Conductor plug wires (PN 32089) on

our modified 3800. Their design came out of stock car

and road racing several years ago. They have low

resistance but radio frequency interference (RFI)

suppression equal that of stock wires. The Super

Conductor core is Kevlar around which is a

tightly-wound, copper wire. A foot this stuff has about

40-feet of coiled wire which acts like an RF choke and

suppresses RFI. The outer sleeve is heat, abrasion and

tear resistant. Add super grippy connectors and durable,

heat-resistant silicone boots, the choice of black or

red and you’ve got a great plug wire. Super

Conductors’ lower resistance increases the performance

margin of our ignition system, which could come in handy

later, and the high suppression keeps the Tom Henry RS's

Monsoon sound system noise-free.

We stuck a Stant 180° thermostat (PN 45848) in

place of the stock 195° unit. Running the

cooling system at 180° may reduce the engine’s

tendency to detonate and will improve durability

of underhood rubber and plastic. Next we swapped

the O.E. drive belt for a Goodyear Gatorback

Poly-V belt (PN 4060940). Its diamond-checked

back allows the Gatorback to run up to 15°

cooler, extending belt life. Lastly, we added a

bottle of Red Line WaterWetter to the coolant.

WatterWetter can improve cooling performance

when the engine is run hard. |

|

|

|

The

Goodyear Gatorback belt, by virtue of its

diamond-checked backing, generates less heat as it

flexes around the pulleys. This lengthens belt life. The

Stant 180 ‘stat is an easy swap on a 3.8L V6. CHpg

staff.

|

|

|

|

|

The Goodyear Eagle

F1 GS-D3, known for its “flying-V”

tread, is an outstanding performer on

wet roads and one of the better,

all-round, ultraperformance radials on

the market . CHpg staff. |

|

Speaking of Goodyear, the last big American tire

company, its Eagle F1 GS-D3 is a killer, all-weather,

ultraperformance radial tire. It has good dry traction

and, by virtue of its distinctive tread pattern which

aggressively channels water away from the tread, great

performance on wet roads. It also has excellent tread

life and low noise characteristics. Lastly, it has

Goodyear’s neat “Rim-Guard” feature which lowers the

chance of wheel damage if we scrape a curb. We swapped

the stock, T-rated, 235/55R16s for a GS-D3s in

P245/50ZR16. As these Z28-sized tires fit on our stock

16x8-in. wheels, the switch was simple. We ordered the

GS-D3s from Tucker Tire in Covina California, then had

Tucker’s professionals mount and balance them. |

|

Now, we needed a little

DIY computer reprogramming. We used a Hypertech Power

Programmer (PN 30009) to lower our engine control

module's (ECM) fan-on temperatures to match the 180°

thermostat, to alter the vehicle speed limiter above

what was stock with T-rated tires and optimize the

speedometer calibration for the

slightly-smaller-diameter, Goodyear F1 GS-D3s.

Working a Little Harder

The first mods where

easy but now, we’ll earn our pay. Under the back of this

Camaro was that gleaming Flowmaster exhaust but a

nasty-looking rear end. We didn’t want to take the rear

end apart to have the housing grit blasted before we

could paint it because, then we’d have to set-up the

gears. Not!

The Eastwood Company

has a paint called “Rust Encapsulator” which spokesman,

John Sloane, told us, “...is a slow-cure enamel,

fortified with a fine glass-flake amendment which seals

the surface.”

Seal the surface and

rusting virtually stops. “R.E.” can be used alone or as

a primer, over which you can apply just about any paint.

It’s intended for spray application after thinning with

20% lacquer thinner, but can be brushed on, if you add

10% retarder.

|

|

|

|

ECM calibration was a task with which we became very

familiar on this project. Our first attempt, was pretty

basic. We used a Hypertech Power Programmer to lower the

fan-on temps and to change the ECM’s tire size

programming to work with the 245/50ZR16 Goodyears. As

time went on, as you'll read in future installments of

this project, calibration became our bane. CHpg staff. |

|

|

|

|

Our

initial experience with Rust Encapsulator was

brushing it on but buying the aerosol version is a

better idea. Either way, RE saved a lot of work. CHpg

staff. |

|

We plugged the brake

hose connection on the chassis, then got the Camaro’s

axle out, stripped-off the brakes, capped-off the

caliper hoses, masked its vent and ABS sensor

connection.

Some aftermarket

service data, like the

Haynes Repair Manual,

claims you shouldn’t remove brake components because

that lets air in the system then a scan tester is

required to bled it. That’s bunk. It is true that, in

the unlikely situation that you loose enough brake fluid

such that the ABS brake valve drains, you need the scan

tester to bleed the ABS; however, when you remove the

rear axle or the front calipers, immediately plug the

connections on the chassis and the brake hoses. Once you

reconnect the brake plumbing, bleed the brakes manually

to get the small amount of air out of the lines and

hoses and you're set. |

|

|

|

Since we

had both the Flowmaster exhaust off and the

rear axle out, not only did we use the Karcher 2650HH to

wash the rear axle but we blasted the whole underneath

of the back of the car. Image: CHpg staff. |

Next we cleaned the

rear axle with warm water and Simple Green using a

Karcher 2650HH Pressure Washer we bought at Costco. We

blew the axle dry with shop air, masked-off the brake

hoses and the parking brake levers then painted it with

Rust Encapsulator (PN16040Z). After overnight drying, we

shot it with Eastwood Extreme Chassis Black (PN11175Z).

After a second overnight dry we reinstalled the axle,

reassembled the brakes then bled the rear calipers. |

|

|

|

“Chassis

Black” has been around for years but,

recently, Eastwood revised its formula,

adding to the product’s already good

durability. We used new, “Extreme

Chassis Black” on the Camaro’s rear axle. How ‘bout that snazzy

spray gizmo on the can? We found that at Ace Hardware.

Image: CHpg staff. |

|

|

|

|

Getting

the axle in-and-out of a 4th-gen is easy and moving it

is a snap with a floor jack. A second set of jack-stands

supported the axle while we hung the new suspension.

Image: CHpg staff.

|

|

Global West Suspension

Systems, an engineering-driven manufacturer of

high-performance suspension pieces for Camaros and other

Chevys, has a brand called “Quiet Ride”. These products

combine polyurethane or rubber bushings with spherical

bearings for a decrease in deflection but only a modest

increase in harshness. Quiet Ride parts are for

high-performance street use, not racing, and are

available from Tom Henry Racing.

|

|

|

|

The GW rear arms each have a rubber bushing and a

spherical bearing. Rubber goes in the body pickup point

and the bearing bolts to the axle. Image: CHpg staff. |

|

|

|

Here are

most of the pieces we used in the rear.

The Bilsteins have heavy-duty valving which improve the

handling of any 4th-gen Camaro. Image: CHpg staff. |

|

|

Once the

control arms are in place, set the isolator atop the

spring, then raise the spring, such that its top goes

into the spring seat, then push it onto the rear axle.

Image: CHpg staff.

|

|

|

|

Between the much stiffer

lower control arms and the aggressively-valved Bilstein shocks, the rear suspension

is going to deflect less and better damped. Access the

shocks’ top nuts through the interior. On the bulkhead

behind the rear seat are two carpeted access flaps. Fold

them back, pull out the sponge insulators and there are

the nuts. Once the shocks’ lower bolts are tight, you

can take the rear end off the jacks. Image: CHpg staff. |

|

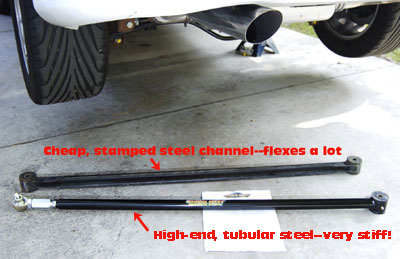

We

bolted-on Quiet Ride tubular steel, rear control arms (PN

TBC14) which fit ‘82-’02 Camaros and offer an increase

in rigidity over the stamped-steel stockers. GW arms use

a Moog, rubber bushing in the body end and a spherical

bearing on the axle end. These arms can be installed in

an hour.

Next,

we ordered Eibach Springs and Bilstein high-pressure,

gas shocks. The rear Eibachs are a stiffer, progressive

rate design, dual-rated at 75 and 135 pounds-per-inch.

They lower the car about 1.5-in. and are part of the

“Pro Kit” (PN

3870.240)

for V6 Camaros. The Bilsteins' (PN

B46-1914) stiffer

damping is an excellent match for our spring rates and

ride height. We added a 19-mm, Z28 rear stabilizer bar.

We used the production Camaro mounts and end links but

installed Global West polyurethane link bushings (PN

19-428).

|

|

|

Side-by-side

are the stock and Global West trackbars.

The GW upgrade offers an increase in rigidity and is of

value to any modified Camaro, be it an autocrosser or a

drag racer. Image: CHpg staff. |

|

|

One neat

feature of the Global West Trackbar is that

it's adjustable so the chassis can be centered on the

rear suspension no matter what the ride height. You

loosen the nuts then turn the hex section as necessary

to center the chassis. Image: CHpg staff. |

|

|

The rear

stabilizer and Global West Trackbar are in

place, so the rear is done, except for centering.

Image: CHpg staff.

|

|

We

finished the rear with a Global West, Quiet Ride

Trackbar (PN PHC3), an improvement over the flimsy,

rubber-bushed stocker. Made of tubular steel with a poly

bushing in one end and a bearing in the other, it’s a

stiffer lateral link so suspension deflection during

cornering is reduced. It’s adjustable for length, so the

body can be centered, regardless of ride height. All

these rear suspension parts came from Tom Henry Racing.

|

|

|

Aftermarket service manuals say to use a pickle fork and

a hammer to separate ball joints and tie rod ends. Not!

That's a lot of work and it renders good parts unusable.

Use a ball-joint and tie-rod removal tool like this

one--it's much easier on you and the parts. Image: CHpg

staff. |

|

On to the front

suspension. We pulled off the front brakes, popped the

ball joints loose then removed the steering knuckles,

the struts and the front control arms. Let's take a

minute to expand upon the subject of polyurethane

suspension parts. "Poly" is common in suspension

upgrades, however, it's not appropriate in all

situations. Urethane is more rigid than rubber so, on a

car with ride travel typical of road cars, when a

suspension nears compression and rebound limits,

urethane can bind suspensions which have control arms

which twist as well as move up-and-down. Examples are

rear bushings in 4th-gen front lower arms or the

bushings in the rear arms. On the street, if you want

reduced deflection, it’s better to use

high-durometer-rubber bushings from the FE7 suspension.

Some may know these as “1LE bushings”, though they were

on cars other than 1LEs. These bushings noticeably

decrease deflection, however, they won't bind the

suspension on street cars nor are they overly harsh.

|

|

We ordered stock, FE7

front lower bushings (PN 22145392 and 22156434) from the

Tom Henry Racing. We, also, ordered Moog’s “enhanced

design” lower ball joints (PN 6145T) which have

pressed-in rather than folded-over bottom plates and

come with grease fittings, both durability and

performance upgrades. Moog is a supplier to NASCAR, so

if they’re good enough for the Busch and Cup guys;

they’re good enough for us.

Both the bushings and

the ball-joints have to be pressed-in. Since we were

ordering the parts from THR, we shipped the arms to Tom

Henry Chevrolet's Service Department and had them run

next door and get the parts, install them and ship the

arms back. Finally, we wet-abraded the lower arms using

Standard Abrasives Medium BriteRite Pads with hot Simple

Green and water. We dried them with shop air then, then

shot them with Eastwood Extreme Chassis Black.

|

|

|

|

The Tom Henry Chevrolet

Service Department uses an assembly of

J-Tools in a hydraulic press to install

and automatically set the position of

bushings. Their positions in the front

lower arm is critical to avoid

interference between the arm and the crossmember when

the suspension rebounds. You can install bushings using

traditional methods, but you must set them at specific

positions. Push the front bushing in from the rear until

3/16-1/4-in. is left exposed. Push the rear bushing in

from the bottom, until 7/16-1/2-in. protrudes above the

arm. Image: CHpg staff |

|

When

reinstalling control arms with rubber bushings, have the

arms at ride height while tightening the bolts. Bushings

don't rotate, they twist. Tighten the bolts with the

suspension hanging and, when it returns to ride height;

the bushings are constantly twisted. When the suspension

nears full compression, they’ll really be twisted, which

can damage the bushings. Also, with the rear bushing in

the front lower arm of a 4th-gen car, if you tighten the

bolt with the suspension hanging, the bushing may turn

off-axis in the crossmember. If that happens, setting

alignment is difficult, the misaligned bushing can cause

increased harshness and the crossmember and bushing may

be damaged.

We

disassembled the front strut assemblies, scrapped the

stock springs and shocks then installed the stock spring

seats, 377 lb/in. front springs out of the Eibach Pro

Kit and the stock upper spring mounts onto two Bilstein

shocks (PN B46-1913).

|

|

|

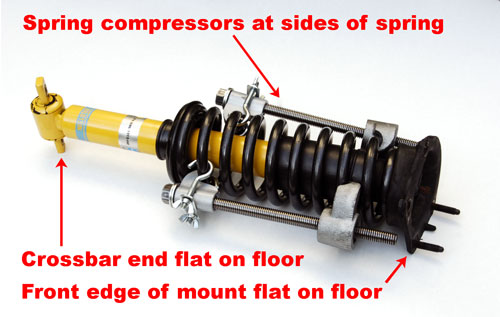

While

the procedure of using the garage floor

or other flat surface as a "jig" while

assembling the struts seems

all-too-simple--it works very well.

Image: CHpg

staff. |

|

The

Tom Henry service department uses a high-dollar, J-tool

jig in a hydraulic press to assemble 4th-gen front

struts, equipment out-of-reach of most DIYs. You can use

ordinary strut compressors if you orient the shock’s

lower mounting bar and the upper strut mount in specific

positions while tightening the shock absorber nut.

Your

“jig” is your garage or shop floor. Each strut mount has

two threaded studs and a rubber pin near its front edge.

Once the struts are assembled with the springs

compressed, the springs’ upper ends seated in the strut

mounts and the shock absorber nuts loose, lay the struts

with the front edge of each mount flat on the floor.

Rotate the left shock so the end of its lower mounting

bar is flat on the floor and (looking at the strut top)

inclined down to the right (pointed outside the

vehicle). Rotate the right shock so the end of its

mounting bar is flat on the floor with (looking at the

strut top) the crossbar inclined downwards to the left

(pointed outside the vehicle). Now, tighten the shock

nut and remove the spring compressors and you’re ready

to stick your struts back on the car.

|

|

|

The Global

West Del-A-Lum is really a bearing not a bushing. The

blue aluminum shell is pressed into the control arm. The

gold steel sleeve rides on the control arm shaft or bolt

and is locked in place. The Delrin sleeve "floats"

between the two. Layers of grease are between all the

parts. Del-A-Lums are a better choice than polyurethane

bushings because they never squeak, do not bind the

suspension and have better durability. Image: Global

West Suspension. |

|

Next,

we had the Tom Henry Service Department install Global

West Del-A-Lum “bushings” in the car's stock uppper

control arms. Del-A-Lums are not really bushings but

Delrin/Aluminum composite suspension bearings. Swapping

the stock rubber bushings for Global's parts eliminate

deflection of the front upper arms under cornering loads

which makes the car's handling more predictable and

consistent. Since the Tom Henry RS is still primarily a

street car, the Del-A-Lums in the uppers and the

production 1LE rubber bushings we installed in the lower

control arms make a great combination. The lower arms

take virtually all the impact loads, so keeping rubber

in those arms allows us to retain a modest level of

compliance to keep impact harshness and noise at an

acceptable level. Since we had the upper arms off, once

the Del-A-Lums were in place we, also, added new, Moog

heavy-duty ball joints (PN K6462) to the arms.

|

|

|

The OE

bushing (left) and the Del-A-Lum.

Obviously, the Del-A-Lum is a

less compliant, but not quite as

stiff as a solid metal bushing.

The delrin-aluminum composite

design with the parts separated

by grease makes for outstanding

durability. It's not uncommon to

have Global West Del-A-Lum

outlast the car it's on. Image:

CHpg Staff. |

|

|

|

|

The

THRS's stock front upper control

arms fitted with Global West

parts and Moog ball joints.

Image: CHpg Staff. |

|

|

|

|

Like

most suspension "bushings" the

Del-A-Lums are best installed

using a hydraulic press along

with a small, temporary "spacer"

to keep the arm from collapsing

when the bushing shell is

pressed into the arm. Image:

CHpg Staff. |

|

We

assembled the arms and the control arm mounting brackets

then stuck the refurbished lower arms, the Eibach/Bilstein

struts, the mod'ed upper arms, the steering knuckles, a

pair of Moog tie rod ends (PN ES3238RL) and all the

brake hardware back on the car.

|

|

|

The upper arm, its

mounting bracket and the strut are

installed as a unit. Guide the strut

mount studs though the shock tower, hold

the lower control arm down then push the

strut’s lower mount onto the arm. Image: CHpg

staff. |

|

|

|

|

We

bolted the front brakes in place, bled them and we were

done with the front, except for an alignment. Image: CHpg staff.

|

|

|

|

|

This is

the SPX Kent-Moore tool which alignment shops should use

when setting the camber and caster on the front of a

4th-gen Camaro. You can do the alignment without the

tool, however you'll end up with the lower control arm

bushings preloaded and that tends to decrease their

reliability-durability. Image: CHpg

staff. |

|

While we're on the

subject of doing the job right, let's talk about tools.

Marketed by SPX Kent-Moore, GMs supplier of service

equipment, specialized tools (Techs at Tom Henry

Chevrolet Service call them “J-Tools”) are sometimes

needed. J-Tools for bushing installation and strut

assembly are not necessary, however, the “Caster/Camber

Adjusting Tool” (J-38658) is required. You can’t adjust

camber without it because you end-up tightening the

bushing bolts with the suspension hanging.

Our front suspension

upgrade ended with a stock Z28, 30-mm front

stabilizer bar from and Global West polyurethane

mounts (PN

19-1146) and links (PN 19-409) from THR. |

|

With suspension mods

done for now, we bolted the Goodyear F1 GS-D3s back on

and took the Tom Henry RS to Tucker Tire for front end

alignment and to center the rear using the GW Track

Bar’s adjustment.

|

|

|

|

Amanda Dakai, a Tucker Tire suspension technician, works

the camber/caster gauge. Tucker Tire is one of L.A.’s

top suspension centers with four alignment racks running

all day long. Yes, you need a reservation. Image: CHpg

staff. |

|

Just One More Thing

|

|

|

Installing higher-ratio rockers on a 3800 in a Camaro is

fairly easy. You remove the ignition hardware, pull the

valve covers then trade the stock rocker bolts, rockers,

pushrods and support bar for the SLP parts. Image: CHpg

staff.

|

|

The final step in Part

One of the Tom Henry RS project was to install a set of

SLP Performance Parts, 1.8:1-ratio, rocker arms on the

car's 3800 V6. These come in a kit that includes

.300-in. longer pushrods and new GM rocker arm bolts.

Longer pushrods are required because the SLP rocker's

pushrod seat is 3/10th of an inch higher than stock and

the new bolts are necessary because the O.E. units are

"torque-to-yield" fasteners which cannot be reused. |

|

|

|

Where as the stock

rockers are investment-cast steel with a

roller fulcrum, the SLPs are machined aluminum

with roller fulcrum and tip. They are about

half-an-ounce lighter. Image: CHpg staff. |

|

|

|

|

While changing

rockers on our 3800 Series II, we

prelubed the rockers with Red Line

10W30 oil and we dabbed some Red LIne

Assembly Lube on the valve stem tips.

Also, you must replace the rocker

bolts, if you stick with GM bolts. ARP

makes a reusable 3800 rocker bolt

and later in the project, we'll

install a set.

Image: CHpg staff. |

|

|

|

|

We're almost ready to

put the valve covers back on. We still

need to squirt some Red LIne 10W30, into

the top of each rocker, stick new Fel-Pro

gaskets in the covers then

reinstall them. Then, we'll put the

ignition hardware back on and go

testing. Image: CHpg staff. |

|

The

stock rocker ratio is 1.6:1. Higher ratio rocker arms

offer more valve lift and duration for a given lobe

lift. The stock cam for an unblown 3800 has .256-in.

lobe lift. With that cam, valve lift with stock rockers

is .410" but with the SLP 1.8s, it's .460". Generally,

more valve lift means more air into the engine and more

power out.

Another difference between the SLP 1.8s and the stock

rockers is 0.5-oz. less weight per rocker. In theory, a

lighter rocker taking mass out of the valvetrain should

improve the engine's ability to "RPM", however, right

now, the engine in the Tom Henry RS peaks at 5000 rpm

and we've still got the stock rev. limiter in the ECM

calibration so even if the SLPs do offer an advantage at

high rpm, at this point; we can't use it.

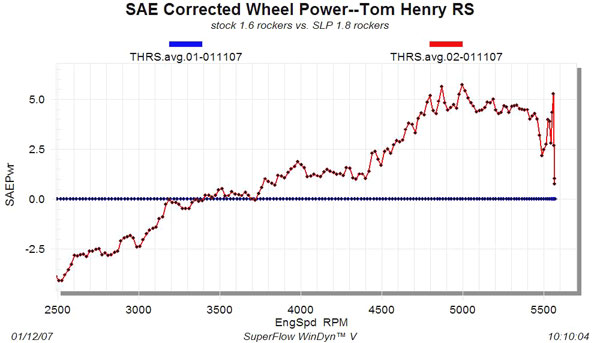

With

the SLP rockers installed, we went back to the chassis

dyno at Westech. In a series of six passes on their

Superflow 840, three with stock rockers and three with

the SLP 1.8s, the results were mixed. At 4900-5000 rpm

we saw just a hair less than a 6-hp average increase,

but below 3400 rpm, we saw as much as a 3.5-hp loss.

This increase up high but a loss down low is typical of

adding both lift and duration. Nevertheless, from

3700-up, there's a consistent increase so, in the real

world, on the street or the drag strip, you might see a

slight decrease in e.t.

|

|

|

Most of

the time, you see chassis dyno information as curves.

Superflow's software can do a lot of interesting number

crunching. This graph offers a more visual

representation of the improvement that we got with the

SLP rockers. The blue baseline is the average of three

passes on Westech's SF840 before the rockers. The red

graph is the average power improvement below or above

the baseline from three runs with the 1.8 rockers

installed. We don't know why this representation style

is used more often because we think it's a better way.

Image: CHpg staff. |

|

This

particular 1.8 rocker is not available direct from SLP

but is sold by LM Performance. The manufacturer of these

rockers was Yella Terra, an Australian company which

makes performance products for 3800 Series II V6es

(down-under, they call it the "Ecotec 3800") and

private-labeled them for SLP. Once LMPerformance sells

out of the SLP 1.8s, V6 Camaro DIYs will be able to get

to Yella Terra's "second-design" 3.8 rocker which is

available in both 1.8:1 and 1.7:1 ratios. Later in this

project we'll acquire a set of the Yella Terra 1.8s and

test them but, for now, the SLPs work quite well.

We'll

be back in about two months with the second installment

of the Tom Henry RS built-up in which we'll really

roll-up our sleeves and turn some wrenches. We'll start

with cylinder head modifications.

Click here to read Tom

Henry RS Project Part 2

Sources:

All the

GM parts and most of the aftermarket parts discussed in

this article are available from Tom Henry Racing at

www.tomhenryracing.com. The products not available from

THR are listed below:

|

American

Kleaner Mfg.

(Karcher Pressure Washers)

Box 3900

Rancho Cucamonga CA 91729

909.481.4333

www.karcher-usa.com |

Eastwood

Company

263 Shoemaker Rd.

Pottstown PA 19464

800.345.1178

www.eastwoodcompany.com |

|

Haynes

Publications, Inc.

861 Lawrence Dr.

Newbury Park, CA 91320

800.442.9637

www.haynes.com/na.html |

Helm,

Inc.

14310

Hamilton Ave.

Highland Park, MI 48203

800.782.4356

www.helminc.com |

LMPerformance, Inc.

PO Box 534

Destin, FL 32540-0534

850.654.4730

www.lmperformance.com |

SPX Kent-Moore

28635 Mound Road

Warren, Michigan 48092-3499

800.468.6657

www.spxkentmoore.com |

Rockauto

rockauto.com |

Valco

Cincinnati

411 Circle Freeway Dr.

Cincinnati, Ohio 45246

800.788.3865

www.valco-cp.com

|

Vericom

Computers, Inc.

14320 James Road

Suite 200

Rogers, MN 55374 USA

800.533.5547

www.vericomcomputers.com |

Westech

Performance Group

Unit C

11098 Venture Av.

Mira Loma CA 91752

951.685.4767

www.westechperformance.com

|

|