|

Building the Tom Henry RS

Pt 2: Heads and Valvetrain

|

|

|

Image: CHpg Staff. |

|

In the first part of this series, a Flowmaster exhaust,

SLP 1.8:1 rockers and other, minor bolt-ons, gained us

17-hp at the wheels. Clearly, our V6 Camaro's response

to mods is promising and there's potential in the 3800

Series II engine, so now, we're going to get more

serious about performance enhancement.

Get that 2010 Feeling

One reason we're modifying the engine in the Tom Henry

RS is, as stated previously, to use our '01 Camaro's hot

rodded powertrain to attempt to simulate the performance

of the 5th Gen, 2010 Camaro which will sell the most: the

entry-level V6.

The obvious base engine for '10 is a further-developed

version of GM's "Global V6 Engine" which, in it's "3.6L

V6 VVT" version, is new this year in a number of GM

passenger cars including the Pontiac G6, the Cadillac

CTS and the Holden VE Commodore, and ranges from

255-275hp.

|

|

|

These tools remove the 3800's harmonic

damper. On a five-speed car, lock the driveline with a

big screwdriver. Really lean on that breaker bar and the

bolt will loosen. With the bolt out, you still need a

puller to get the damper off. The Kent-Moore puller

works best, but others may, too, if you use 5/16x1

bolts. Longer bolts will break the trigger wheel on the

back of the balancer. When replacing the balancer bolt,

use the same killer breaker bar but with a torque angle

meter and tighten the bolt to 111 ft/lbs plus 114°.

Yep–that's tight. Image: CHpg Staff.

|

|

With the Tom Henry RS project, our goal is 260hp. The

3800 Series II, four times listed on the annual "Wards's

10 Best Engines" list in the late 1990s, has an ideal

foundation for our project because its short block was

designed with a 260hp supercharged application (still in

production at GM, today) in mind. To meet our goal, we

won't need to do anything to the block, crank, rods or

pistons. Our mod'ing will be confined to the camshaft

and the top end of the motor. We'll begin by porting the

heads, installing bigger valves and changing the cam.

Do-it-yourselfers can handle the tasks discussed here,

but some will be challenging. While most of those tough

jobs can be completed with tools advanced DIYs possess,

you'll need a few special items. To remove the

crankshaft balancer bolt requires a 2-foot Breaker Bar

and a 15/16 in. impact socket and, again, we chose Mac

Tools products (PN VF24FAPA and PN VP306R). |

The cam change requires an SPX Kent-Moore Power Steering

Pulley Remover (J-25034-C), Crankshaft Balancer Remover

(J-38197-A) and a Front Cover Seal Installer

(J-35354-A). An inch-pound torque wrench such as the Mac

Tools, 0-150 in/lb. unit (PN TWDFX150N) comes in handy

during reassembly of some of the small fasteners used to

hold intake parts. Required for head bolts, the harmonic

damper bolt and other fasteners is a torque angle meter

and we got that (PN TM281) from our Mac man, too.

You need service data and the best is in the

Camaro Service Manual

for your model year. A lower-cost alternative is the

1993-2002 Camaro Haynes Repair Manual

but instructions in it are very condensed and have a few

errors.

If you're working along with us, you know it's a vicious

rumor that modern GM engines use all metric hardware.

You'll find a mix of metric and fractional fasteners

because the 3800's distant ancestor is the 231 cubic

inch Buick V6, designed a generation ago, before the

industry's metric conversion was complete.

Ok. Let's get to work

|

Off came ignition hardware, EGR pieces and miscellaneous

bracketry. Using fuel line disconnect tools in a

Kent-Moore

"Port Fuel Injection Diagnostic Kit" (PN

J-37088-A),

we disconnected the fuel system, removed the rocker

covers and pulled the valve gear. We detached the drive

belt tensioner assembly, removed the fuel rail, lifted

the upper and lower intake manifolds and removed the

power steering pump pulley but left the pump mounted on

the block. Finally, we got the exhaust manifolds off and

removed the heads. To avoid the tedious job of removing

the ignition mounting bracket from the left head, remove

the head with the bracket in place, then once you have

the head sitting on the bench; remove the bracket. |

|

|

|

Tear down the engine with

care. If you're not good at remembering

where stuff goes, mark or tag fasteners.

Same is true of wiring harness plugs and

hose connections. A clean engine is a

happy engine so, washing and (where

necessary) painting parts is something

we learned to love.

Image: CHpg Staff |

|

Next to come off was the harmonic damper, one of the

challenging tasks mentioned earlier. The damper is a

modest press-fit on the crank snout but its bolt is

about 3/4" in diameter with a 15/16" hex and is

incredibly tight. A 3/4-drive, or very powerful

1/2-drive, air impact wrench fitted with a 15/16" impact

socket will break it loose but, to make room for that,

you need to remove the front stabilizer bar. For us, it

was easier to put the 15/16" socket on a Mac Tools

breaker bar, brace our feet on the right front tire and

really pull on the breaker bar. That broke the bolt

loose, but it took every bit of strength we could

muster.

We slipped off the balancer then disassembled the

crankshaft position sensor and its shield. Some non-GM

shop manuals imply that you leave the oil pan alone when

pulling the front cover. Not. Remove the front three pan

bolts and loosen all but the two rear bolts by a quarter

inch or so. That drops the front of the pan enough to

separate its gasket from the front cover. Pull the cover

forward, off its dowel pin, then up and away. Next, we

removed the timing chain tensioner, chain and sprockets,

lifters and took out the cam.

Pay no attention to non-GM manuals which say that, to

change the cam, you remove the fans, radiator and air

conditioning condenser which forces an A/C recharge.

With our '01 Camaro, we got the cam out without all that

work and it wasn't difficult. Other model years might be

the same way.

Cylinder Head Prep

|

For head work on the Tom Henry RS project, we chose Mark

DeGroff's Cylinder Head Service and Machine Shop in

Northridge, California. First, DeGroff's Kent Grodske

disassembled the heads and examined all parts for

unusual wear. There was none, so Grodske gave the head

castings a good session in the wheel abrader and

then in the solvent tank followed by a blow-dry.

Next came a magnetic particle inspection of the

castings looking for cracks, especially around

the exhaust valve seats.

|

|

|

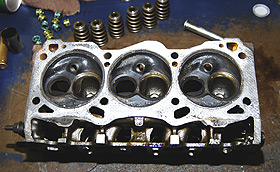

One of our 3800 Series

II heads, stripped-down and ready for

the solvent tank.

Image: CHpg Staff. |

|

|

|

|

At Mark DeGroff's Cylinder Head Service, Ken

Grodske performs a magnetic particle inspection. The

horseshoe device generates a magnetic field. Ken

sprinkles metal powder on the casting. If there's a

crack, the powder forms a pattern over it.

Image: CHpg

Staff.

|

|

Before we cut Mark DeGroff loose with his porting tools,

we hauled the bare heads back to our shop for some

preliminaries. Using some carbide burrs (PN 46067) we

got from the Eastwood Company along with various

cartridge rolls and rotary stones from a Standard

Abrasives Head Porting Kit (PN 260001), we enlarged,

then deburred the pushrod passages in the heads which

double as oil return passages. The point of this was to

improve oil return to the pan. Then, we deburred and

detailed the exterior of the castings.

|

|

|

To enhance oil drainback, using Standard

Abrasives Motorsports Division products, we enlarged and

deburred the heads' oil return passages. Then, we

lightly deburred their exteriors. Any cylinder head

performance upgrade would include those steps.

Image: CHpg Staff. |

|

Finally, we spayed the castings with brake cleaner,

wiped them down with Eastwood "Pre" paint prep spray (PN

10041Z) and dried them with shop air. To further enhance

oil return, we painted the tops of the heads and the

pushrod/oil return holes with Eastwood Gyptal (PN

46000Z). We stuck the valve covers on to mask-off what

we'd just done, then shot the exteriors with Eastwood

Chevrolet Orange (PN 10016Z). After an overnight drying,

we took the heads back to DeGroff's. |

Mark's first order of business was to flow test the O.E.

intake and exhaust ports. He installed stock valves back

in one of the chambers and tested the ports on his

Quadrant Scientific FlowLab 520, flow bench. From .200

to .500 in. valve lift, the stock intakes flowed ok,

but, below .200" and above .500", they needed work.

|

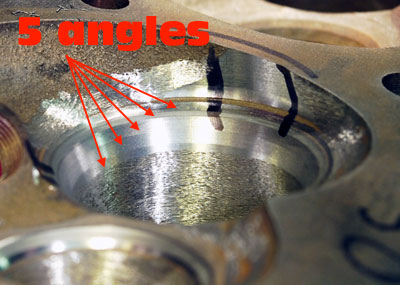

Now it was time to set goals for our 3800 cylinder head

project: significant flow improvement below .200" lift

and between .500" and .600" along with a modest

improvement between .200" and .500". To reach those

targets, Mark DeGroff developed a five-point strategy:

1) machine the seats for the bigger valves, 2)

port/polish the spaces just above the valve seats, 3)

modestly enlarge and polish the intake and exhaust

ports, 4) unshroud the valves, and 5) do a multi-angle

valve job.

|

|

|

|

The guys at Tom Henry

Racing have painted a lot of engine

parts in their days. Eastwood makes some

of the best engine paints we've used. On

a clean part, 2-3 coats of Eastwood

engine paint will last for many years.

Image: CHpg Staff. |

|

Stock valve sizes are 1.80" intake, 1.52", exhaust. You

can install larger valves in 3800 heads, but you're

limited by the induction hardened exhaust valve seats,

part of which are machined away during the process. The

largest exhaust which usually maintains acceptable seat

durability for long-term street use is a 1.57 and a 1.55

is probably safer. With a 1.55 exhaust, a 1.90 intake is

plenty big, if valve proportion is to remain .80-.85,

however, intakes up to 1.97 in. can be used if exhausts

are held to 1.55. We decided on a 1.90". intake and a

1.55". exhaust.

|

|

|

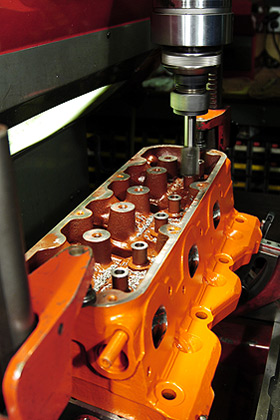

The first step in a DeGroff Port/Polish is to

rough machine the seats for larger valves. This seat

gives Mark a reference point from which to port the

bowls. Image: CHpg Staff |

|

Like many modern vendors of cylinder head preparation

work, DeGroff's Head Service uses a Serdi "Valve Seat

and Guide Machine", specifically a Model 60, to machine

seats and guides. The Serdi advantage is more accurate

machining of those parts of the head. The first of three

sessions for our heads on the Serdi was to rough-cut the

new, larger valve seats which would give Mark DeGroff a

"reference point" to use during the initial enlargement

of the ports just above each seat. Because of their

shape, head porters call these spaces "bowls".

In addition, with our heads getting not only bigger

valves, but multi-angle seats, there is a time savings

in that, with the Serdi, DeGroff could enlarge the seats

and rough-cut the seat angles at the same time. Lastly,

Mark unshrouded the intake valve by taking a light cut

out of the adjacent chamber wall. |

"Bowl work" is a time-honored staple of the head

porting craft. Using a carbide burr along with Standard

Abrasives cartridge rolls, DeGroff enlarged and

contoured the bowls. The intake valve guide bosses were

smoothed and the exhaust guide bosses were removed.

|

|

Bowl-work. Yeah, it's time consuming, but it's

where the air flow is. Mark DeGroff, a bowl-work wizard,

indeed, is at work with the high-speed grinder fitted

with a carbide burr. He's doing preliminary modification

of an exhaust bowl which brings the valve throat to a

diameter appropriate for the new, bigger valve and

cleans-up the rest of the bowl. |

|

|

After the rough bowl work is done with an

Eastwood carbide rotary file, Mark switched to Standard

Abrasives' cartridge rolls to do the finishing work on

the bowls and the chamber walls. Image: CHpg Staff.

|

|

|

When doing the chamber, use old valves to

prevent nicking-up the valve seat area. Image: CHpg

Staff. |

Using Fel-Pro intake gaskets (PN MS95809-1) as a

template, DeGroff enlarged the intake port entries then

ported the intakes down to the bowls. He enlarged the

exhaust ports from the bowl to the port exit in the

head.

|

|

Initial porting of the intake

port entry area is done with a rotary file.

The outline of the port is scribed on the

gasket flange, then the port is opened up to

that size. Sure, you can go larger, but

there'd be little advantage with a street

hi-po motor like our V6.

Image: CHpg Staff. |

|

|

Bright lighting and a

high-speed grinder is essential for good

port work. Either an electric or an air

grinder work well as long as they have a

1/4" chuck. You cannot use a drill motor for

porting. Image: CHpg

Staff. |

|

|

Once the rough work is done,

switch to cartridge rolls to finish the

port. Image: CHpg Staff. |

|

|

The exhaust port exits are done in a manner

similar to the intakes. Image: CHpg Staff.

|

The "short-turn" or "short-side" radius is the holy

grail of cylinder head airflow. It is where the floor of

the port turns downward to the area of the valve seat

closest to the port entry. There may be differing

opinions amongst cylinder head experts about some

aspects of porting, but one issue upon which they all

agree is the importance of the short-turn radius. The

stock heads are really terrible around their short-turn

radii so DeGroff spent a lot of time on the tops of the

bowls and how that area blends, through the short turn

radius, to the port floor.

At this point, we stepped in and assisted DeGroff with

the remaining grunt work: polishing the ports and the

chambers with Standard Abrasives Flap Wheels and

Cross-Buffs.

|

|

If you were sitting on the piston

top, this is what the chamber on a finished DeGroff head

would look like. Image: CHpg Staff. |

|

|

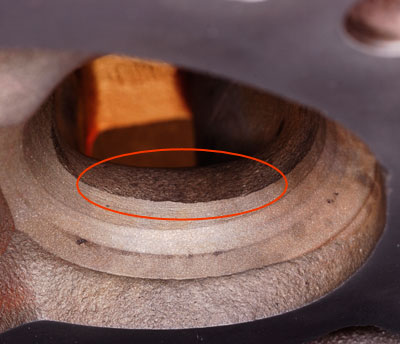

The short-turn radius (inside the red) of the

stock head. Look at that nasty ridge, just above the

valve seat. Man, that's bad. Image: CHpg Staff. |

|

|

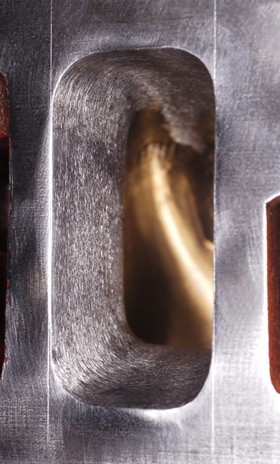

The same spot after DeGroff and our helper got

through with it. Looks pretty cool, huh. It works even

better than it looks. Image: CHpg Staff. |

|

|

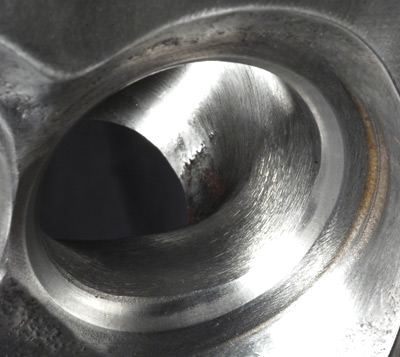

This is the floor of the same port, shot from

the other end, showing how the port floor blends

smoothly into the start of the short-turn radius. Image: CHpg Staff. |

|

|

A stock intake port entry. Image: CHpg Staff. |

|

|

Same port entry, after our port/polish work.

Image: CHpg Staff. |

|

|

The stock exhaust seat and bowl–same ratty

looking ridge just above the valve seat. Image: CHpg

Staff.

|

|

|

The much better exhaust seat and bowl. Image: CHpg Staff. |

|

|

The stock exhaust port, shot from the exit.

Image: CHpg Staff.

|

|

|

The exhaust port in a DeGroff head. Image: CHpg

Staff.

|

With

porting work done, it was time for the valves,

themselves. There are three options for larger valves in

3800 heads. If you're budget-constrained, valves out of

a '97-'04 Corvette's LS1 V8 work, provided you: 1)

reduce the intake to 1.90", 2) with the .175" longer

valves, use .175" shorter pushrods, 3) shim the springs

and 4) know that longer valves and shorter pushrods make

valvetrain geometry less than ideal, but acceptable, as

long as use above 6000 rpm is avoided.

If

you're building an all-out, racing 3800 and cost is no

object, try INTENSE-Racing "Severe Duty" valves.

Developed for 450+ hp. supercharged or turbocharged

3800s and made by Manley Performance Products, they're

stock length, but have 5/16" stems, so you must install

5/16" guides.

Wanting

to avoid geometry issues and figuring Severe Duty valves

were unnecessary to make 260-hp on the motor and 320-hp

with nitrous, we split the difference and

special-ordered Manley, "Gen II Race Master" valves (PN

11204 and 11205) which have stock diameter (8mm) stems.

We specified 1.90," intake, and 1.55," exhaust,

diameters, stock-length and lock grooves in the stock

locations. The Manley intakes are made of NK-842

stainless steel and the exhausts are made of XH-426

stainless which has good reliability and durability at

up to 1200°F. Both have stems hard-chromed to .002"

depth and swirl-polished heads.

|

|

Stock valves (left pair) and the Manley Race

Master valves. The Manleys have stock stem diameters,

are stock length and use stock valve locks. Image: CHpg

Staff.

|

|

|

Look at those pretty, swirl-polished heads on

our Manley valves! Image: CHpg Staff. |

|

|

|

The valves were faced with a Sunnen valve

grinding machine. Image: CHpg Staff |

|

Manley Race Masters are an excellent choice for

our application, unblown, nitrous oxide,

under-8000 rpm in an aggressive,

high-performance street or racing duty cycle.

While costing more than LS1 pieces, Gen II Race

Masters preserve proper valve train geometry and cost a

third less than Severe Duty units plus--you don't need

new guides. Mark DeGroff chucked the Manley intake and

exhaust valves in his Sunnen valve grinding machine and

put a two-angle, 30°/45° face on each. |

The

next step was to move the heads back to the Serdi

Machine and do the final cut of the valve seats. The

precision Serdi is a real time saver

in that it cuts all the valve seat angles at

once with better accuracy than

old-style, valve seat grinders. In addition, when

necessary, it can machine curved surfaces rather than

multiple angles. For the intake seats, Mark fitted the Serdi with a specially-made cutter, selected by DeGroff

Cylinder Head Service for optimum results in

high-performance applications, which cuts a five-angle

seat (35°, 45°, 55°, 65°, 75°) with the 45° seat angle

1mm wide. On the exhausts, DeGroff used his own #1

High-Performance cutter to machine a

two-angle-plus-radiused seat which starts with a 30° top

cut, goes to a 45deg 1.5mm wide seat then a 10mm

descending radius where the seat transitions to the

bowl. The final step was the time-honored hand lapping

of the valves and seats.

|

|

Mark DeGroff at the controls of the Serdi 60,

finishing-up the valve seats. Image: CHpg Staff. |

|

|

The Serdi uses a pilot in the valve guide to

index. Valve seats are machined rather than ground.

Image: CHpg Staff.

|

|

|

An enhancement to accuracy and time savings is

that the Serdi cuts all angles or radii of a muti-angle

valve seat at once. Image: CHpg Staff. |

|

|

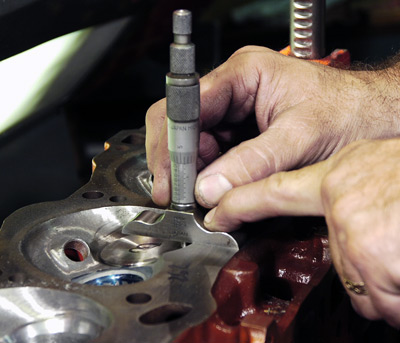

The valve seats are cut such that the valve is a

specific distance below the head deck and that dimension

is checked with a depth micrometer.

Image: CHpg Staff. |

|

|

The final step in a DeGroff street port/polish

job is hand-lapping of the valve faces and seats. Image:

CHpg Staff.

|

|

|

One of our Manleys, lapped and ready for final

assembly. Image: CHpg Staff. |

|

|

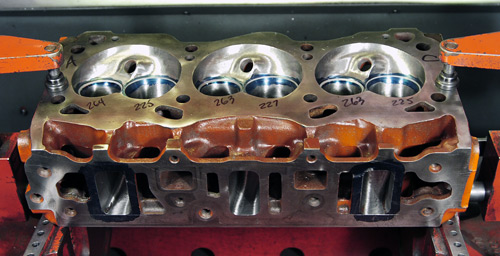

A DeGroff 3800 Series II head, ready for final

flow test. Image: CHpg Staff.

|

Next,

it was back to DeGroff's Quadrant Scientific flow bench

to test our work. The results in the tables below were

achieved with a test pressure of 28 inches of water.

Production

|

Lift

inches |

Intake Flow

CFM |

Exhaust Flow

CFM |

Ratio |

|

.100 |

56.8 |

45.8 |

.80 |

|

.200 |

112.8 |

100.2 |

.92 |

|

.300 |

159.0 |

132.0 |

.81 |

|

.400 |

180.6 |

144.7 |

.78 |

|

.500 |

188.0 |

145.5 |

.76 |

|

.600 |

192.6 |

151.3 |

.76 |

DeGroff modified

|

Lift

Inches |

Intake Flow

CFM |

Change |

Exhaust Flow

CFM |

Change |

Ratio |

|

.100 |

71.9 |

22% |

59.22 |

28.8% |

.82 |

|

.200 |

134.7 |

21% |

124.8 |

22.2% |

.93 |

|

.300 |

189.7 |

17% |

152.2 |

15.4% |

.88 |

|

.400 |

202.8 |

10% |

167.0 |

12.2% |

.82 |

|

.500 |

208.5 |

6% |

172.7 |

16.1% |

.85 |

|

.600 |

212.2 |

8% |

173.1 |

15.4% |

.82 |

As you can see, we achieved the goals set at the onset

of our head modification program.

|

|

|

The flow bench never lies. The big C-clamp and

the modeling clay might not be high-tech, but they work

well. The FlowLab equipment is no longer made, perhaps

because it was too technologically-advanced and

expensive but, through its computer-controlled

automation, it quickly and accurately flow tests a port.

Image: CHpg Staff. |

|

After an earlier version of this article was published

in the Spring of 2006 in

Camaro Performers

magazine, some members of V6 forum sites were aghast

that we didn't use Abbott Racing Heads for our port

work. Typical of childish behavior sometimes exhibited

on forums, there were even expletive-laced tantrums

posted because we didn't use the head porting vendor the

"clique of experts" felt was best.

Drag racer Lance Abbott has done a lot of racing 3800

cylinder head development using his V6-powered '98

Pontiac Firebird drag racer. Lance told us in a recent

telephone conversation that he's run a 12.48 using his

ported intake, his Stage 3 head, a special Comp Cam,

long-tube headers and a pair of ET Street tires on the

rear. That's one potent 3800! |

Abbott Racing Heads offers three modified cylinder heads

for '95-'02 V6es. Flow numbers on the Abbott web site

show the intake port in their "Stage 3" head clearly

outperforms our DeGroff heads once you go past about

.350" valve lift but we'd expect nothing less from a

head Abbott characterized as an all-out drag racing part

and listed on his web site as containing,

"...every ounce of our 30 years of head porting

experience. We believe these heads will out-perform any

other heads on the market."

People who actually know why certain cylinder head

modifications work understand that intake ports in a set

of heads intended for street high-performance use rather

than hardcore drag racing, may not flow as well at high

valve lifts.

The flow data, also, shows that,

below .300" lift, our DeGroff heads are, actually ,

a little better than the Abbotts. The DeGroff

exhaust, also, flows better below .300" lift than the

Abbott 3 and, interestingly enough, above .300", the

DeGroff exhausts have similar flow characteristics to

the Abbottt.

|

| |

|

|

Intake and exhaust flow charts for stock,

Abbott Stage 3 and DeGroff heads. Graphics: CHpg

Staff.

|

If you want the ultimate 3800 head for drag racing, you

need a vendor experienced with racing head development

for that engine and Abbott Racing Heads is a good

choice. On the other hand, if you're building a 3800 for

street high-performance where good drivability, snappy

throttle response and a wide torque curve is important,

then, on the basis of its superior low-lift flow

numbers; maybe the DeGroff is a better alternative.

|

|

|

The final machining step

with the heads was to lower the valve

guide stem seals by machining the top of

guide. If you're going to use a cam with

over .450" lift, you must perform this

step to prevent contact between the stem

seal and the valve retainer.

Image: CHpg Staff. |

|

Lance Abbott spent countless hours developing his intake

ports and has validated that work with extensive flow

testing along with a lot of drag strip testing. There is

little doubt as to the fruits of this work as Lance's

car as gone mid-12s.

On the other hand, Mark DeGroff had never ported a set

of 3800 heads before we walked in his shop and he only

did one set for this project. In his first and only

attempt, we about equalled or exceeded the air flow

numbers of an all-out racing head except for intake flow

above .350" lift and, we were ok with that because these

were street heads. We wanted modest rather than

drag-race-style intake ports. It'll be interesting what

the kids on the forums have to say, now.

|

|

|

|

Near the end of the port/polish process, Mark

checks the combustion chamber displacement. Image: CHpg

Staff.

|

You seal-off the chamber with a section of

plastic, then fill the chamber with solvent

from a

burette and note the amount of solvent used. That figure

is the chamber displacement. Image: CHpg Staff. |

With

our airflow testing complete, Mark chucked each head

back in the Serdi and machined the tops of the valve

guides. This must be done to gain adequate clearance

between they and the valve spring retainers at maximum

valve lift when a high-lift cam is used. That was

followed by displacement-balancing (or "CC'ing") the

combustion chambers. At this point the head work was

complete.

The

Camaro Homepage's "Top Eight Things to Remember about

Porting 3800 Heads"

1)

Ports in heads which make good power are designed with

size and shape in mind, not just maximum flow at maximum

valve lift.

2) Big

ports make impressive flow numbers, but maybe not a

quick-revving engine. To make power in a hurry, you want

air velocity in the intake ports. Smaller ports with big

flow numbers have velocity.

3) The

short side radius on the intake port is the most

important area in the cylinder head.

4) Most

of the air/fuel mixture flows across as little as 120

degrees of the intake valve's circumference.

5) The

blend area, above the exhaust valve seat is critical to

good flow.

6) You

need a sharp break at the exhaust port exit, not the

common 35- or 38-degree angle.

7) The

color of combustion residue in the chamber tells much

about where the mixture is burning. Ideally, you want

consistent coloration throughout the chamber.

8)

Low-lift flow (.100-.300" lift) is critical to an engine

that revs quick everywhere in its torque curve. You

can't see this on the dyno, but if the heads don't flow

well at low valve lifts; drivers will say that the

engine has poor response.

After a

thorough solvent wash of all parts, DeGroff installed

the valve stem seals out of a Fel-Pro gasket set (PN HS

9917 PT-2), slipped the Manley valves back in place,

added retainers and locks (then measured spring heights

at 1.790" to 1.800", right at the desired, 1.800".

We're

at one of the places in this series where the Tom Henry

RS project on the Camaro Homepage differs dramatically

with the magazine series which published in

Camaro

Performers

during 2005 and 2006, on which this is based. For the

magazine series we used Comp valve springs, retainers

and locks along with the SLP 1.8 rockers. Unfortunately,

that combination didn't work well above 5800 rpm. Beyond

that, there was a significant torque loss caused by

valve float. To complete the project for the magazine,

deadlines forced us to go back to the stock, 1.6:1

rockers to end the valve float. For the Internet version

of this project, because we had more time to solve the

problem, we decided a more sensible solution was to

change some other valvetrain parts to eliminate the

valve float.

Katech,

Inc. (see sidebar) is one of the top Chevrolet race

engine development firms in the World. Its engines have

powered Corvette C5-Rs and C6.Rs to five wins at the 24

Hours of LeMans and six American LeMans Series

Championships in the last eight years.

We

figured there were few better experts on racing and

high-performance valvetrains in GM V6 and V8 engines

than Katech. Since, like the Gen 3/4 V8 family, the 3800

is an OHV engine and since it uses the same lifter,

spring, retainer and lock designs as those V8s; we

figured Katech might have a few suggestions to help us

fix our valve float woes.

|

|

At right is a weak-suck, stock spring. At left

are the Katech springs which were originally designed

for Gen 3 V8 applications and are about the stiffest,

single, beehive spring available for a 3800. Image: CHpg

Staff. |

|

We

contacted Caleb Newman, Katech's Vice President and

Director of Aftermarket Operations. After a couple of

email exchanges and a telephone conversation with

Newman, we decided a little less valvetrain mass and a

slight increase in valve spring pressure might solve our

problem. The first step was to install Katech

Performance "High-Lift Beehive Valve Springs" (PN

PSI-LS1511) which spec at 125-lbs on the seat and

332-lbs open at .550" lift and 352-lbs at .600". This

spring is a bit more aggressive than the Comp 26918 (130

on the seat, 302 at .550" and 318 at .600") we used

initially. We hope the Katech springs along with

Katech's lighter retainers and a new, lower-mass, 1.8:1

rocker we'll tell you about in Pt. 3 will provide the

valvetrain stability we need.

|

|

|

|

Each Katech spring was tested and met its

design specification. Always test

new springs. Image: CHpg

Staff. |

|

Mark

DeGroff tested each Katech spring and all met the

manufacturer's specs. He installed the springs, added a

set of Katech Performance 7° Titanum Retainers (PN

KAT-4678) put the locks in place and our set of DeGroff

heads was complete.

|

|

|

Why did we switch to Katech valve train

parts? Less mass is one reason. L-to-R

are, 10.1-gram, stock steel retainer, Katech's 5.2-gram titanium retainer and

Comp's 7.2-gram titanium retainer which we used

previously. |

|

|

|

DeGroff, using an air-powered spring compressor

to assemble one of our heads. Image: CHpg Staff. |

Camshaft Selection and Installation

Flow testing validated our heads to .600 in. valve lift,

so we targeted .550" lift for our engine. Another issue

we considered is valve noise–the clacking you may hear

when the valves hit the seats in an engine fitted with

an aftermarket camshaft having aggressive closing ramps.

The faster the valve is going when it hits the seat, the

louder that noise will be. Some misidentify valve noise

as lifter noise because the two sound similar, however,

once you use a listening device to pinpoint the source,

it may be obvious that its valve seat noise and not

lifters you're hearing. Sometimes an engine controls'

knock sensing will be fooled by valve noise and the ECM

will enable knock retard (KR) even though no detonation

is present. We call this "false" knock retard.

Anytime you choose an aftermarket cam with

high-intensity lobes for an engine with knock sensors,

you walk a fine-line between having the most aggressive

lobe profile as possible and lobe profiles which are so

noisy when the valves close, that they cause false KR.

Another sticky issue with aftermarket cams and OBD II

engine controls is misfire detection. Many aftermarket,

performance cams have more overlap and lobe centerlines

which are closer together than a stocker. Both

situations may cause the engine to run rough at idle.

Problem is, if the idle is too lopey, OBD II may set a

diagnostic trouble code (DTC) P0300, which is random

misfire.

It is possible to disable certain features of the

on-board diagnostics by reprogramming to preclude the

system from setting misfire codes but that requires

either an experienced calibration engineer or your own

skills with engine controls cal software such as "HP

Tuners".

But, it's too easy to disable parts of OBD II. We like

the challenge in modifying our V6 to the 260hp level but

doing it in such a way that all engine controls

diagnostics continue to function properly, the engine

idles nicely and the engine's exhaust emissions such

that the car can pass the most stringent state exhaust

emissions tests, such as California's infamous BAR97

type "Smog Check". Only those with enough tuning

knowledge to be dangerous or those who are just lazy

avoid this challenge by disabling on-board diagnostics

on street-legal engines.

|

|

|

Mark DeGroff and a set of his 3800 heads. These

heads match some of the best, drag race heads in the

3800 racing community except for flow above .350" lift. DeGroff heads are a perfect choice for a street

high-performance 3800 of 225-275 hp. Image: CHpg Staff. |

Comp Cams has an assortment of 3800 series II cams in

its catalog, however, Comp Engineer, Billy Godbold

suggested a custom-ground cam for this project. Comp

does that regularly and doesn't charge extra for it, so

we took his advice. The "Tom Henry RS cam" is a

hydraulic roller (PN 76-0000-9) with a, #3341 intake

lobe and a #3342 exhaust. Duration at .050 in. lift is

206°, intake and 212°, exhaust. It's ground four degrees

advanced with a 116° lobe separation angle. With 1.6:1

rockers, valve lift is .480-in. With our 1.8:1 rocker

arms, valve lift will be .540", quite a bit more than

the stock, .413".

|

|

|

The backside of the Comp Cams Tom Henry RS

camshaft shows Its custom grinding specs etched on the

of the rear journal. Image: CHpg Staff. |

|

|

|

It's easiest to install the cam from below. Prelube the rear third, tip the rear of the cam up just

slightly and into the engine. As you do this, the front

of the cam will be just inside the passenger side

cooling fan. As the rear journal slides in, level the

cam then push the rear third into the engine. Lube the

remaining lobes and journals, then carefully push the

cam the rest of the way in. Image: CHpg Staff.

|

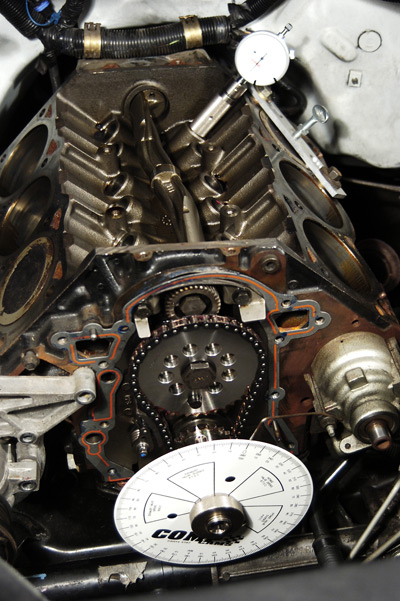

We pre-lubed the cam

with Red Line Engine Assembly Lube which has three times

the film strength of typical assembly lubes and will not

clog oil filters. We installed the cam then added a

Rollmaster single- row timing chain set (PN CS6141). The

Rollmaster is one of the many 3.8 V6 performance parts

manufactured Australia where hot rodding those engines

is big. Rollmaster timing sets are distributed in the

States by the Engine Pro brand. We initially installed

our cam "straight-up", the Rollmaster's crank sprocket

has multiple keyways, allowing as much as 8° advance or

retard. Caution: with cam timing other than straight-up

or valve lift more than .550 in., check piston- to-valve

clearance. It's best to replace the chain damper anytime

the chain is changed, so we added that (PN 24503893)

which we ordered from GM Parts vendor, Tom Henry Racing.

|

|

|

The crank sprocket for an Rollmaster

timing chain assembly. We've highlighted the TDC mark

with orange paint. The multiple keyways are how the

Rollmaster can be adjusted to alter cam phasing. Image:

CHpg Staff.

|

Camshaft degreeing validates cam timing and crankshaft

keyway indexing and is required during a cam change.

Comp Cams' has great camshaft checking equipment. We

used: TDC Deck Plate Stop (PN 4933), 7.5" Degree Wheel

(PN 4787), Crankshaft Socket (PN 4798), GM Cam Degree

Tool (PN 4925), and 1" Dial Indicator (PN 4909).

We used

the "intake centerline" (ICL) method to degree #1 and #3

intake lobes. We turned #1 intake to maximum lift,

zeroed the indicator then rolled the motor over until

got to the base circle and determined the ICL was 118°.

We checked #3 ICL and it, also, was at 118°.

We checked #3 ICL and it, also, was

at 118°. Once we advanced the cam 2°, using the

Rollmaster adjustable Timing Chain, ICL was the 116°

required by Comp Cams.

A detailed explanation of the intake centerline

procedure is in Comp Cams' instruction booklet.

Lastly, we unpacked a set of Comp hydraulic roller

lifters (PN 875-12), to fill the lifters interiors, we

soaked them for several hours in Red Line 10W30

synthetic oil, then dropped them into the lifter bores.

Finally, we replaced the front cover using a Fel-Pro

Timing Cover gasket set (PN TCS45971) and tightened the

oil pan bolts.

|

|

|

The Rollmaster chain assembly, damper and Comp

Cams degree tools are in place and we're ready to degree

the cam. Image: CHpg Staff.

|

.

|

|

|

Comp Cams supplied the

hydraulic roller lifters. We selected Comp's

Pro Magnums because they'll handle fast

acceleration rates and a 6400 RPM rev limit

without pump-up. Image: CHpg Staff. |

The Tom

Henry RS project has a lot of sponsors, but a few

deserve special mention: INTENSE Racing's Scott Cook,

Comp Cams' Billy Godbold, cylinder head wizard Mark

DeGroff, Hypertech's Jim McFarland and Katech's Caleb

Newman went out of their way to help and we appreciate

their efforts.

In Part

Three of the Tom Henry RS project, we'll finish the

engine build-up and we'll do some mods to other parts of

the car. We'll see you back here in a few months.

Project Sponsors:

|

Comp Cams

3406 Democrat Rd.

Memphis, TN 38118

800 365 9145

www.compcams.com |

Mark DeGroff's Cylinder Head Service

18736 Parthenia #2

Northridge, CA 91324

818 701 5274 |

Eastwood Company

263 Shoemaker Rd.

Pottstown PA 19464

800 345 1178

www.eastwoodcompany.com |

Federal Mogul Corporation

(Fel-Pro)

26555 Northwestern Highway

Southfield, Michigan 48034

248-354-7700

www.federal-mogul.com/aftermarket |

Katech, Inc.

24324 Sorrentino Ct.

Clinton Township MI 48035

586.791.4120

www.katechengines.com |

Haynes Publications, Inc.

861 Lawrence Dr.

Newbury Park, CA 91320

800 442 9637

www.haynes.com/na.html |

|

Helm, Inc. (GM Service Manuals)

14310 Hamilton Ave.

Highland Park, MI 48203

800 782 4356

www.helminc.com |

Hypertech

3215 Appling Rd.

Bartlett TN 38133-3999

901 385 1888

www.hytpertech.com |

Per-Fit Corporation (Rollmaster)

728 S. Division

Grand Rapids, MI 49503

616 247-6572

www.romacusa.com |

Mac Tools

505 N. Cleveland Av.

Westerville OH 43082

800 622 8665

www.mactools.com |

Manley Performance Products

1960 Swarthmore Av.

Lakewood NJ 08701

800.526.1362

www.manleyperformance.com |

Red Line Synthetic Oil Corp.

6100 Egret Court

Benicia CA 94510

800 624 7958

www.redlineoil.com |

|

SPX

Kent-Moore

28635

Mound Road

Warren,

Michigan 48092-3499

800-468-6657

www.spxkentmoore.com |

|

Tom Henry Racing

5886 Route 8

Bakerstown PA 15007

877 866 7278

www.tomhenryracing.com |

|