|

Building the Tom Henry RS

Part 5: Brake Service, More Suspension Mods,

Custom Tuning and Making it Pretty

by

Hib Halverson

|

|

|

Image: CHpg Staff |

The

Tom Henry RS, 2001 Camaro project car now has a little

over 104,000 miles on it. Many of those miles have been

"daily driver" duty, but for rest of the time, we've

beat on the car pretty hardclose

to a hundred or so chassis dyno runs and plenty of road

testingso

for this part of the series; we're going to mix

maintenance with modification.

During the camshaft installation covered in Part Two, we

installed a Rollmaster single-row timing chain. For

that, we were criticized by a few "experts" (might they

be "faux experts"?) on forums catering to V6 Camaro and

Firebird owners. They claimed single-row chains are not

reliable in a 3800 Series II with a more radical

camshaft (like Comp Cam with 206/216°

duration, .530" lift), higher spring pressure (Katech

valve springs), higher rocker ratio (1.8:1 Yella Terra

aluminum roller rockers) and a higher rpm range (6400

rpm rev limiter). The

experts

said we were foolish to use a single-row chain because

our engine would experience certain failure in short

order.

Installation of double row chains require removal of the

engine's balance shaft. We preferred not to do because

that shaft reduces engine shake at idle and low speeds

which we see as a desirable quality for a street car, so

we stayed with the single-row chain.

Fast

forwardfive

years later.

After running the single-row Rollmaster for 50,000 milesthat,

alone, seems a testament to the chain's reliabilitywe

decided it was high time to put the single-row chain

durability issue to rest. We pulled off the front cover,

inspected the sprockets then compared any slack in the

existing chain to that in a new chain.

The

procedure for replacing a 3800 timing chain was detailed

in Part Two, but to quickly review: Remove the drive

belt, the heater hoses, the belt tensioner, the power

steering pulley and the harmonic damper. The damper bolt

is way tight. Even our 1/2-drive air impact wrench

wouldn't break it loose. I had to brace myself and use

my feet on a Matco 24-in. breaker bar (PN C24FC) to get

the bolt loose. With the bolt out, the damper comes off

with a standard puller, then you remove the crankshaft

position sensor and its harness, lower the front of the

oil pan then get the front cover off.

What

did we find after five years and 50,000 miles? Were the

Internet "experts" correct?

Not.

We

removed the chain tensioner and measured the chain slack

with a dial indicator. Then, we removed the sprockets

and inspected them with a magnifier and a bright light.

Only a small amount of wear was visible on the teeth. It

looked more like the slight burnishing you'd get during

break-in. Those sprockets are good for another 50,000

miles, at least. We reinstalled them so as not to skew

the slack measurement of a new chain.

|

|

|

Left is the cam sprocket

we took out. Right is a new Rollmaster

unit we got from Engine Pro. The wear on

the used part is minormore

like burnishing rather than real wear on

the teeth. Image: CHpg Staff. |

|

Like

the Yella Terra roller rockers installed for Part Three,

Rollmaster timing sets are made in Australia where

there's a big market for 3800 Series 2 performance

parts. We took a new single-row chain out of a timing

set (PN CS6141) we obtained from Rollmaster's U.S.

Distributor, Engine Pro, and installed it on our

existing sprockets.

|

|

|

The Engine Pro's

Rollmaster single-row chain set fits

3800 Series II engines and includes oil

pump drive, sprockets and chain.

Image: CHpg Staff. |

|

We

could measure no practical difference in chain slack

between the old chain and the new one. With the chain

tensioner removed, chain slack of both measured

0.530-in. give-or-take a few thousandths. Clearly, the

single-row, Rollmaster chains Engine Pro distributes

have excellent durability in a valve train such as that

of the Tom Henry RS's V6. We left the new chain in place

and our used Rollmaster will make an excellent spare.

|

|

We took chain slack measurements with a

dial indicator. So not to skew the measurements, we used

the sprockets originally in our engine and only swapped

the chains. Slack difference was negligible. Image: CHpg

Staff.

|

Before we put the front cover on, we replaced the chain

tensioner with a new GM unit (PN 24503893), then we

washed parts we were going to reuse in "Extreme Simple

Green Motorsports Cleaner & Degreaser". Since the

service trade is moving to more

environmentally-friendly, aqueous parts washing and it's

slowly catching on in the enthusiast community, we've

been trying Simple Green's Motorsports product for about

a year. It's required a little change in our parts

cleaning habits, but the results have been acceptable in

the majority of parts cleaning situations we encounter.

|

|

|

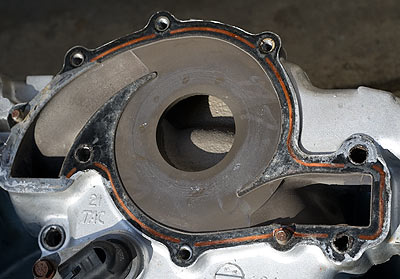

Does periodic cooling system maintenance

pay off? This is the water pump chamber in our engine's

timing cover after a decade and 104,000 miles. There is

no corrosion of any kind. In fact, you can still see the

original coating GM put on the cover. Image: CHpg Staff.

|

We

replaced the coolant pump with a new GM unit (PN

19209288). We added a new front cover gasket out of a

FelPro timing cover set (PN 45971) then reinstalled the

front cover. After that, we installed a new front seal

using a Kent-Moore seal installing tool (PN J 35354).

While it's possible to "knock" the seal in place with a

hammer, the Kent-Moore tool does the job faster and

prevents mangled seals or damage to the aluminum cover.

For

a while, we'd noticed the oil pressure gauge was either

pegged or fluctuating, a sign of the "bad oil pressure

sender syndrome", so we screwed in a new GM sender (PN

19244510). The chain tensioner, the water pump and the

oil sender came from our GM Parts source, Tom Henry

Racing.

The

final major task in our timing chain validation session

was reinstalling the harmonic damper. It's a modest

press fit onto the crankshaft and you pull it on using

the stock damper bolt. Once the damper is on, that bolt

needs to be very tight111

ft/lbs plus another 114°

measured with a Matco torque angle meter (PN TAG281).

Done by hand, the strength of a body builder is

required. Clearly, I need to spend more time at the gym

because, again, I had to put my feet on the Matco

breaker bar to get 114°

additional torque angle.

Upper End Service

Some

discount long-term durability of aluminum roller rocker

arms. Our position is that if the design is sound, the

materials are high-quality, the use does not exceed

design limits and there is proper lubrication, after

market roller rockers last a long time. We decided see

if our Yella Terra, Ultralite 1.8:1 rockers, which had

been in place for three years and 38,000 miles, showed

any wear.

|

|

|

Roller rocker arm. We neither saw nor

felt any wear. The valve stem ends of our Manley valves,

our Katech titanium retainers and Katech valve springs

all looked good. Image: CHpg Staff. |

We

pulled the spark plugs, removed the plug wires, unbolted

the ignition system, then popped off both rocker covers

and removed all the rockers. On the work bench, we

inspected each under bright light and felt how the

trunnion needle bearing and roller tip worked. We could

detect nothing other some modest wear of the pushrod

seats so we reinstalled the rockers, stuck some new

Fel-Pro rocker cover gaskets (VS50080R) in the covers,

bolted them back in place and reinstalled the ignition

system. Since the plug wires had been installed for Part

One of this series seven years and 59,000 miles ago, we

added a fresh set of MSD Super Conductor plug wires (PN

32089) which we like for their high level of RFI

suppression but low resistance. On the plug end of each

wire we use a Design Engineering "Protect-a-Boot" which

is a double-stitched, two-ply glass-fiber "sock" that

goes over the spark plug boot and can withstand 1200°F

direct heat. Protect-a-Boots are great for preventing

thermal damage to the plug boots on engines with

headers. DEI markets these only in sets of two or eight

so we ordered three sets of two in silver (PN 010501).

Since the beginning of the project, we've used Denso

Iridium Power IT-20 spark plugs in our 3800. While Denso

recommends the IT-16, considering its level of

modification and how hard we drive the engine, our

three-eight runs better with plugs one heat range

colder. We prefer Densos because the Iridium Power

design incorporates a small, 0.4-mm center electrode and

a cut-back, u-shaped ground electrode. Both these

features expose more of the combustion chamber's charge

to the spark. The Denso's iridium center electrode has

lower

resistance and better durability than platinum.

We reinstalled our Denso plugs

and pushed the Protect-a-Booted plug wires in place.

|

|

|

A Denso reman alternator solved our

charge voltage problem and we completed the installation

with a new Goodyear Gatorback drive belt. It's about a

15-minute job to change both. Image: CHpg Staff.

|

Continuing our maintenance, we replaced the alternator.

For a couple of months, we observed an intermittent

problem with high charge voltage and when it's up high,

the voltage fluctuates causing the interior lights to

flicker. Often this is a sign of a bad voltage

regulator, so we replaced the 10-year old, 100,000-mile

stocker with a Denso Remanufactured unit (PN 210-5118)

which solved the problem. We also installed a new

Goodyear Gatorback (4060945) drive belt which we prefer

for its diamond-checked backing which allows the belt to

run cooler and last longer. We were on a rollwanting

to preempt any starting troubles, we replaced the car's

original starter with a new Remy Gold unit (PN 96211)

obtained from Internet parts source, RockAuto.com, which

we choose for its great web-based catalog, competitive

prices and quick service.

Cooler Cooling

About a 40% increase in power and, once we add nitrous

oxide, a 75% increase, means we need modificationsbeyond

the Hypertech 180°

thermostat we'd installed a while backto

improve cooling.

|

|

|

Long overdue for the Tom

Henry RS was an improvement in cooling

performance. On pursuing that, we

compared two aftermarket alternatives.

Image: CHpg Staff. |

We

evaluated two aftermarket radiators capable of better

cooling. The first is a Spectra Premium radiator (PN

CU1485) sold by RockAuto. Like the OE radiator, the

Spectra is a single-row, aluminum-core/plastic-tank

design but it has a 1-in thick core offering an increase

in cooling over a stock 0.625-in. core. This radiator is

for cars with either manual or automatic transmissions.

The Spectra drops right into the stock cooling stack and

RockAuto's price is quite reasonable. In fact, you can

get the Spectra Premium with its thicker core from

RockAuto for less money than an O.E. replacement ACDelco

radiator which has a thinner core. The result? A useful

improvement in cooling performance at reasonable cost.

If you have 3800 modified to the 250-300-hp level,

RockAuto's Spectra Premium radiator makes great sense.

|

|

Rear is the OE V6

radiator. Middle is the Spectra Premium

radiator we ordered from RockAuto.com.

Front is the FLUIDYNE High-Performance

unit. CHpg Staff. |

The

second radiator we tried, capable of an even greater

cooling improvementbut

with an understandably higher pricecomes

from FLUIDYNE High-Performance. Some may know FLUIDYNE

as a maker of radiators used in NASCAR racing, but the

company custom builds radiators for modified street,

street/track as well as all-out race cars. It recently

announced an all-aluminum, two-row radiator ideal for

'93-'02 Camaros with V6es having significant

modifications such as, superchargers, turbochargers or

big doses of nitrous oxide.

This

radiator (PN FHP-20-34322-CAMV6) is a serious

pieceincorporating technology FLUIDYNE uses in making

its NASCAR radiators.

It uses the "Thin-Line" core which is a two-row,

1.5-inch, high-fin-count, mini-tube cooler. The

Thin-Line core provides better cooling from: two rows of

tubes, dense fin count and increased water turbulence

inside the smaller tubes. The Thin-Line core is also

very light, resulting in a radiator weighing only

11-pounds. This part is manufactured with the Nocolok,

furnace-brazing process which offers superior

reliability and durability compared to products using

welded construction and epoxy sealing. Typical of most

FLUIDYNE High-Performance products for use in

production-based applications, it drops right into the

stock radiator mounts, accepts the stock electric fan

assembly, stock hoses and offers a significant increase

in cooling compared to the weak-suck, skinny-cored

stocker. This radiator would probably support 450-hp.

|

|

|

Both the Spectra and the FLUIDYNE bolt

into the stock Camaro radiator mounts and accept the

stock fan assembly and the upper support. Image: CHpg

Staff.

|

This

project car is ten years old, so we scrapped the stock

coolant hoses and finished the radiator installation

with new, Goodyear, radiator hoses (PNs 62153, 62154)

and heater hoses (PNs 63301, 64268, 63906). All that

Goodyear stuff we ordered from RockAuto.

Since we were changing the water pump as well as the

radiator, we started with a dry cooling system which we

filled with a mix of distilled water and a bottle of Red

Line Water Wetter. Since straight water is a better

coolant that 50/50 mixes of water and antifreeze and

because this car is based in the coastal Southern

California where sub-freezing temperatures are rare and

never occur long enough to freeze the coolant, but hot

weather abounds; we run water and Water Wetter for

coolant. While that mix works quite well from a cooling

performance standpoint, there are some limitations:

first, you must change coolant every two years

regardless of mileage. Second you need Red Line Water

Wetter for its package of corrosion inhibiters and

anti-foaming agents which is similar to that used in GM

Dexcool. Third, if the temperature where the car is

parked or stored goes below freezing for more

than a couple of hours, you must add antifreeze.

The combination of either the Spectra Premium or the

FLUIDYNE radiator, distilled water, Red Line Water

Wetter, a Hypertech 180 thermostat and lower fan-on

temperatures in the ECM calibration has the Tom Henry RS

running cooler and with a large cushion of cooling

performance.

|

|

|

The FLUIDYNE is an

all-aluminum design. It's connections

are in the stock locations and it has

stock type of mounts for the HVAC

condenser and the electric fan assembly.

Image: CHpg Staff. |

|

|

|

|

Red Line Water Wetter is

mandatory if you use straight water for

coolant. Its main ingredients are 1) a

surfactant, or wetting agent, which

improves heat transfer from the engine's

metal parts to the coolant and 2) a

corrosion inhibitor package similar to

that used in Dexcool. Image: Red Line

Synthetic Oil Corp. |

|

|

|

|

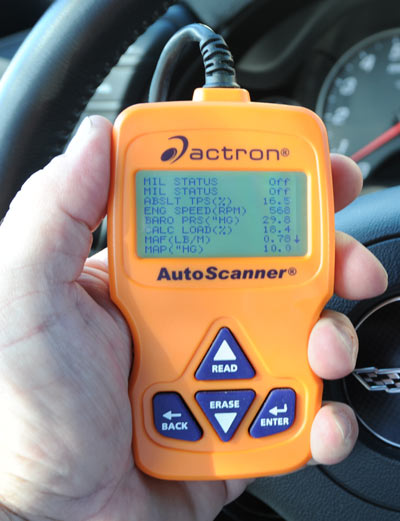

We had occasional

problems with DTC P0128 setting in the

ECM memory. On a temporary basis we

carried an Actron AutoScanner in the

glove box to clear codes when 0128 set.

The little Actron is our favorite

entry-level scan tester. Image: CHpg

Staff. |

In

fact, the FLUIDYNE occasionally is "too good" at

cooling. During winter, code P0128, one of GM's enhanced

diagnostic trouble codes (DTC), sometimes has set our

the PCM. This happens when the PCM decides the engine is

taking too long to warm-up. This code is one of the odd

DTCs which does not turn on the check engine light, but

when it sets, the temperature gauge goes to zero and the

cooling fans stay on.

This

problem occurs on cold days, after a cold start followed

soon after, by highway driving. The high cooling

airflow, coupled with the FLUIDYNE's cooling ability,

has the engine warming up too slowly and that causes the

system to flunk the diagnostic test and set the code. We

carry an Actron "AutoScanner" (PN CP9575) in the glove

box. While it only displays generic OBD II codes, this

handy little scanner can erase any code in the ECM. The

first couple of times P0128 set, we used it to clear

codes. Later, in this article well

reprogram the ECM such that this code wont

set.

Restriction Reduction

The

exhaust system on the Tom Henry RS was one of the first

modifications we made and its Flowmaster "American

Thunder" cat-back has worked quite well. The system has

been on the car since 2004 and after seven years, it was

rusting in a few places and its silver paint was a bit

natty. We pulled the system off and sent the parts to

Extreme Performance Heat Coatings in Oxnard, California

to have them grit blasted then coated with Extremes

Cermachrome

which is a durable metallic-ceramic material with

chrome-appearing finish. We reinstalled the system then

admired the brilliant, Extreme-coated, Flowmaster parts.

As

cool as it looked, one thing bugged us about the cars

exhaust: while the Flowmaster system has 3-inch pipe

back to the muffler, the S-bent section between the

catalytic converter and catbacks

inlet is 2 1/4-in pipe. To get rid of that restriction

required a new, three-inch S-pipe and the folks at

Flowmaster were kind enough to make the pipe for us.

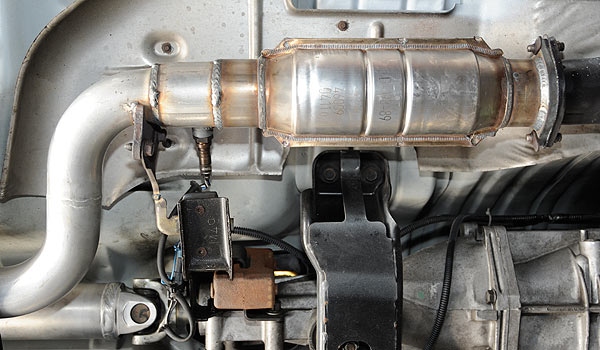

Because the car has 100K+ miles on it and the stock

catalytic convertor's case was damaged, we, also, wanted

a new cat from Magnaflow. This replacement unit (PN

46006) is legal for sale in California. We took the

larger diameter S-pipe and the new cat to Big John's

Performance, an exhaust system specialist in Valencia,

California, and had its ace fabricator, Steve Munson,

install both.

|

|

At Big John's, first step

was to cut some short sections of 3-inch

tubing which would be used to connect

the S-pipe and the cat. Image: CHpg

Staff. |

|

|

|

The

catylitic converter is a "universal fit"

pare, so welding is required and having

an experienced exhaust fabricator, like

Steve Munson, doing the work, ensured

the S-pipe installation and the cat

replacement were done right and in a

short about of time. Image: CHpg Staff. |

|

|

|

|

Once the S-pipe/cat

assembly was tacked in place, we checked

alignment and clearances of the entire

exhaust. Then, Munson did the final

welding. Image: CHpg Staff. |

|

|

|

With the welding done, we

bolted the cat to our Y-pipe, installed

the rear oxygen sensor and reinstalled

the center exhaust hanger. Thanks to Big

John's Performance for a job well-done.

Image: CHpg Staff. |

We

returned to the Westech Performance Group for another

session on its Superflow AutoDyn chassis dynamometer.

Three more runs on the AutoDyn showed that, compared to

our last visit to Westech for Part Four, performance

increased by an average 4.5-rwhp and 5.5-lbs/ft

rear-wheel torque in the mid range and

3.6-rwhp/3.4-lbs/ft at high rpm. Our best run with the

new S-pipe and cat was 223.3-rwhp@5780-rpm and

218.4-lbs/ft@4630-rpm. There was another benefit of the

3-in. S-pipe and new cat: the THRS sounded even better

than beforethe

sound was deeper and a little louder.

|

|

|

After the exhaust work, we had the Tom

Henry RS back at Westech Performance Group to validate

the lower-restriction S-pipe. It was worth about 4.5

horsesmore

than we expected. Image: CHpg Staff.

|

|

|

Some of the tools we come

to use a lot working on the Tom Henry RS

are Gear Wrenches. We were familiar with

Gear Wrench but just never got on the

bandwagon until lately. Now that we've

used them, we don't know how we got

along without them. In fact, nowadays we

hardly use our traditional combination

wrenches. We have two sets of the

flex-head, ratcheting combination

wrenches, metric and SAE. All use Gear

Wrench's ratcheting box-end which needs

as little as 5

to turn the fastener before it can be

ratcheted. Their serrated beams allows

us to feel which way to pull. The

flex-head tilts up to 90

each way and the flex-head has

adjustable tension using a set screw.

Each set comes in a handy

storage/carrying rack. We love these

Gear Wrenches. Image: CHpg Staff. |

Click for

Page 2 ->

|