|

Building the Tom Henry RS

Part 5,

Page2

Brake Maintenance and Upgrade

In a

testament to the durability of stock GM brake pads–or

maybe it's that we're easy on brakes–we

went 10 years and 100,000 miles on the car's original

binders. Though the pads had adequate thickness and

there were no apparent problems elsewhere, as a

preemptive move; it was time for brake service. We also

wanted to repaint the calipers using an Eastwood Brake

Caliper Paint Kit (PN 11838 Z). We did this before but

decided, after six years, to do it again because, in

spots, the paint was chipped or flaking.

|

|

|

The Eastwood Brake Caliper Paint Kit works quite

well–except

for those sponge "brushes". The adhesive which holds the

sponge to the handle is dissolved by some of the

substances one might use to clean them after use. We

went to Ace Hardware and buying some real paint brushes.

Other than that, we love Eastwood Caliper paint,

but...proper surface preparation is required if you want

the paint to really stick. We learned the hard way that

cleaning and painting the calipers on the car doesn't

work real well. Image: CHpg Staff. |

With

the car on stands and the wheels off, we started at the

front by cleaning the suspension and brakes with our

Karcher Pressure Blaster and Simple Green "Heavy-Duty

Cleaner and Degreaser", a product designed specifically

for warm water pressure blasters. Next, following

instructions in the 2001 Camaro Service Manual, we

removed the brake calipers and pads, rotors and front

hubs.

|

|

|

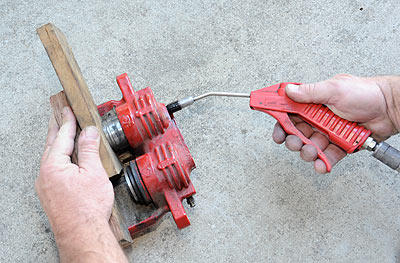

To get the pistons out of the front calipers, we

used a "two-step" block of wood and then turned the

regulator on our compressor way down and applied air

pressure very carefully, just enough so the pistons

gently "popped" out of the calipers. Image: CHpg Staff. |

When

you tear the calipers down, safely remove the pistons by

putting a short section of 2x4 between the caliper

piston bores and the outside brake pad mounting surface

then use air pressure to push the pistons out. You can

use two pieces of wood in a stepped arrangement to make

it easier get both pistons out. Keep your fingers out of

the way and apply air pressure slowly from a blow gun

you can control easily. When they pop loose, the wood

keeps them from shooting across the shop.

We

washed the calipers with Simple Green Motorsports

Cleaner and Degreaser and scrubbed the really dirty

spots with Norton Bear-Tex, a woven abrasive, general

purpose hand pad. We inspected the bores and found them

to be like new, a testament to our periodic flushes of

the brake system since '01. With modern brake calipers,

since they have piston seals stationary in the caliper

bores, honing is unnecessary. If there's light corrosion

or scale in the bores, it can be removed with some fine

sandpaper or a Bear-Tex pad.

When

we blew the calipers dry, more of the original paint

flaked away. The first time we painted the calipers, we

did it on the car. As a result, our preparation

insufficient. Since the first painting didn't adhere

well, washing, then blowing dry made the problem worse

by lifting more of the paint.

|

|

|

The Eastwood Powder Coat and Paint Dissolver

takes a while to work but it does a good job if you

scrub the toughest spots with a parts brush. It's a

little stinky, so we did the work outside. Image: CHpg

Staff. |

Now,

we had to get all the paint off and, for that, we used

Eastwood Company's "Powder Coat and Paint Dissolver". We

filled a two gallon pot with it, dropped the caliper in

and, with occasional agitation and a little scrubbing

with a parts cleaning brush, let the Dissolver work for

about four hours per caliper. The Dissolver is

water-soluble and washes off. Next, we scrubbed the

calipers in Simple Green Degreaser, again, rinsed them,

then blew them dry.

|

|

|

After using the Dissolver then washing the

caliper castings with Simple Green and water, we sprayed

them down with Eastwood's "Pre" and wiped them down. Pre

is a great surface prep for just about any automotive

parts painting task.

Image: CHpg Staff.

|

Next

we sprayed the calipers with Eastwood's "Pre", a surface

preparation product, then gave each one final wipe down

with one of the Kimberly-Clarke Wypalls we like to use.

We mixed the caliper paint and hardener per its

instructions. Once the hardener is added, the paint has

a relatively short "cup life" so some planning is

necessary. Do the calipers two at a time. Have them

ready to go before you mix the paint. Give them one

coat, then put the paint in the refrigerator and wait

45-60-minutes then give each a second coat. The faster

you can paint, the better but, keep in mind that if you

go too fast, you'll make a bit of a mess so put some

newspaper down. You may find it easer to mix the paint

in a smaller quantity but that makes measuring the

hardener difficult with the large cup Eastwood puts in

their kit. We suggest one of those tiny plastic

measuring cups which come with some cough medicines and

a smaller four or six ounce mixing cup.

|

|

|

We did the caliper painting in two stages, rears

first, then fronts so we mixed two separate batches of

the paint. We gave each caliper body, two coats. Image:

CHpg Staff. |

The

best way to apply this coating is with a small paint

brush. A conventional brush with bristles rather than

sponge works better. We gave each caliper two coats of

Eastwood's Red Caliper Paint. We hastened the hardening

process by baking them in the oven for 45 minutes at 250°F

then let them cool overnight.

The

caliper guide pins and the guide pin bores in the

caliper mounting brackets must be cleaned of all grease

residue. Gun cleaning brushes work well for that. We

cleaned the exterior of the mounting brackets with some

more Simple Green Motorsports Degreaser, dried them,

then painted them with a couple of coats of Eastwood’s

Silver High-Temp Coating (PN10396 Z)

Finally, the pistons must be cleaned and ours required

little more than a wipe down with some brake cleaner and

a wipe dry using a Wypall. If your pistons are dirty,

under no circumstances should you use abrasives to

clean them. If you can't clean the pistons with

non-abrasive methods, replace them.

|

|

|

Once the paint dried, we wiped the piston bores

and installed the piston seals out of the GM rebuild

kits. Shown are the front calipers. Assembly of the rear

calipers is similar. Image: CHpg Staff. |

|

|

|

Next, we installed the boots, smeared some brake

assembly lube on the pistons then pushed them in place.

Image: CHpg Staff. |

|

|

|

Once all the pistons were installed, we bolted

the caliper mounting brackets to the calipers. The

caliper guide pin bolts must be torqued 23 ft/lb. Image:

CHpg Staff. |

|

|

|

The final step was to load the calipers with our

Baer brake pads then set them aside for later

installation on the car. Image: CHpg Staff. |

The

next step was to assemble the brake calipers using GM

Caliper Repair Kits (PN 18026160, front, four required,

and PN12530687, rear, two required) sourced from Tom

Henry Racing. First, apply brake assembly lube to the

caliper bores, the pistons and the seals. Put the piston

seals in the bores. Install the piston boots on the

pistons and push the pistons into the calipers. Assemble

the calipers and mounting brackets by smearing silicone

grease on the guide pins and installing new pin boots

and guide pin bolts out of the repair kits. The last

step was to install the two pad abutment shims and an

anti-rattle spring then load each caliper with Baer

"Decelapads" (PN D0749, front and D0750, rear). We

selected Decelapads because they're a good choice for

the high-performance street duty cycle.

|

|

|

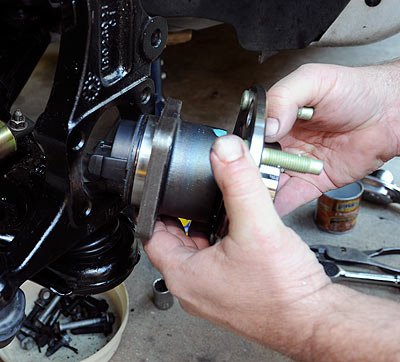

After 104,000 miles, on "GP" we decided to

install two new front hubs. We kept the old ones as

spares. We ordered two ACDelco aftermarket units from

RockAuto.com. Installation was as simple as

disconnecting the ABS wire, unbolting the old, bolting

on the new and reconnecting the ABS. Image: CHpg Staff. |

|

|

|

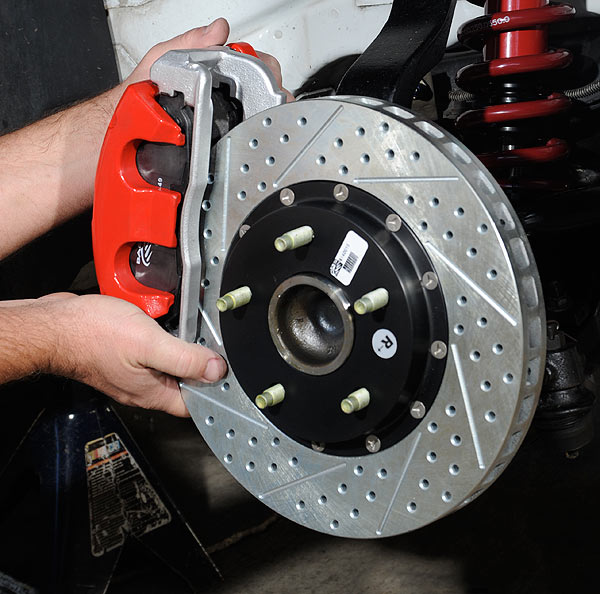

Following the new hubs, we installed our

Baer two-piece rotors and our rebuilt/repainted calipers

and new Baer brake pads. Image: CHpg Staff

|

In

the front, we installed two, new, AC Delco wheel

bearing/front hub assemblies (PN 2086) from RockAuto.com

followed by a fresh pair of Baer Eradispeed-Plus brake

rotors (PN 2301006). These are a racing-style, two-piece

combination of an aluminum "hat" and a bolt-on, grooved

and drilled cast iron brake disc. Eradispeed-Plus rotors

have an enhanced vane design for improved brake cooling

and are made with premium materials. The final step was

caliper installation with Valco Cincinnati Medium

Strength Thread Locker applied to the caliper bracket

bolts and the bolts torqued to 74 ft/lbs.

|

|

|

In the rear, we went for Baer's Eradispeed

rotors along the Deceapads. Image: CHpg Staff. |

At

the rear, the caliper rebuild and painting process is

similar to what's covered above in the discussion on

front brakes. Once the calipers and rotors are removed,

inspect the parking brake hardware. If the shoe assembly

is worn, replace it. Disassemble and clean the brake

springs and adjuster.

We

installed two Baer Eradispeed (PN 55050-020) one-piece

grooved and drilled rotors. Our repainted rear calipers,

loaded with the Baer pads, went on next. The caliper

bracket bolts were cleaned, the threads given a couple

of drops of Valco Cincinnati Medium Strength Thread

Locker then torqued to 74 ft/lbs.

With

the calipers and rotors in place, we moved on to the

master brake cylinder. At this writing, mid-September,

2011, the master cylinder repair kit for '98-'02 Camaros

(PN 18029859 or ACDelco PN 175431) has been discontinued

by General Motors and is no longer available from Chevy

dealers, however, the ACDelco version of this part (PN

175-431) is still sold by RockAuto.com. Our research

showed that in spite of listing the part as

"discontinued" GM still had stock of this part in its

Lansing, Michigan warehouse. We suspect RockAuto will

continue to sell this until the stock is exhausted. Once

the repair kits are gone, if you have a faulty master

cylinder; your only choices will be a new cylinder from

GM or a new or remanufactured cylinder from the

aftermarket.

If

you're one of the lucky ones who can get a repair kit–to

service the cylinder, chuck its mounting flange in a

vise and release the reservoir by knocking out the

roll-pin retainers. Depress the piston assembly with a

round-ended tool, remove the retainer, then pull out the

primary piston assembly. Cover the inlets and the rear

outlet then apply low pressure air to the front outlet

to push out the secondary piston assembly and the return

spring.

Clean the interior and exterior of the cylinder with

denatured alcohol then inspect the cylinder bore with a

bright light. If you see cracks, scoring, corrosion or

pitting, scrap the cylinder and get a new one. The bores

in aluminum master cylinders cannot be honed. If the

secondary piston hardware is damaged or corroded you,

also, must replace the cylinder.

Our master cylinder's bore and secondary piston were in

good condition. Knowing we were going to do a brake job

on a car with 104,000 miles, luckily, we had ordered a

GM repair kit earlier in the year from our GM parts

source Tom Henry Racing. We used its contents to

replace the secondary piston seals and seal retainer

then reinstalled the secondary piston. We followed that

with the new primary piston assembly included in the

repair kit. Finally, we reinstalled the piston retainer

and the reservoir.

|

|

|

When you start with a dry master cylinder,

you must bench-bleed the cylinder before bleeding the

rest of the brake system. We used one of Dorman's Bench

Bleed kits which we got from RockAuto.com. Image: CHpg

Staff. |

|

|

|

A recent acquisition in our shop is one of these

Motive Power Bleeders. This unit is ideal for DIYs who

do frequent brake work but are not working in a service

trade environment. The Power Bleeder is simple to use

and the model we have includes adapters to fit the

master cylinders of many Camaros and other GM vehicles.

Image: CHpg Staff. |

|

A

rebuilt or new master cylinder must be bench bled

before reinstallation. Use either either a Cardone (PN

105000MCB) or Dorman (PN 13911 for metric and SAE or PN

13999 for metric only), bench bleeding kit, both of

which are available from Rock/Auto. Once it's

bench-bled, reinstall the cylinder per the Service

Manual.

The

last step in our brake work was to flush and bled the

system using a Motive Products "Power Bleeder Kit" (PN

0254) which is designed specifically for GM vehicles. We

like the Power Bleeder for its small size, that it fits

many GM vehicles back to the late '60s and that it

provides the same results you'd get from a

professional-grade pressure bleeder at less cost. Added

benefits are the Power Bleeder's convenient size and

light weight. We, also, like the product's clever

design, originally done by a DIY enthusiast and that the

company's current owners are also DIYs. Using the Motive

Bleeder, we bled the Tom Henry RS's brakes per the

instructions for pressure bleeding in the 2001 Camaro

Service Manual and that included using a Bosch

Mastertech scan tester to "re-home" the motors in the

ABS brake pressure modulator valve.

|

Additional, more specific information on '98-'02 Camaro

brake service, consult the Camaro Service Manual.

New

Suspension Mods

One

goal we had for Part 5 of the THRS project was taking

our Camaro's suspension to the next level. After consultation with

Doug Norrdin, owner of one of our suspension sponsors,

Global West Suspension, we decided to try a new

spring/shock package consisting of: 600-lb/in. Eibach

front springs, Global West 190-lb/in., constant-rate,

rear springs and QA1 double-adjustable shocks. In the

front, Global West groups the Eibach spring and QA1 "DA"

shocks along with some additional parts of its own

design, into a coil-over-shock assembly (PN CO32-SR).

The rear shocks are a stand-alone, QA1 pieces (PN

TD704).

There are a number of advantages to the QA1s, the first

being, by virtue of the QA1s' aluminum shock bodies, a

slight decrease in unsprung weight over the Bilsteins we

ran before. Shocks which are separately-adjustable for

both compression and rebound simply by turning dials on

their exteriors have great appeal on a car like ours

which is, at various times, street-driven, driven hard

on twisty roads or run on a drag strip. The QA1 Double

Adjustable front shock for 4th Gen F-cars is a

coil-over-shock design so it, also, offers

easily-adjustable, front ride height.

|

|

|

Our revised front suspension uses a Global West

coil-over-shock assembly. Key parts of that are Eibach

Springs and QA1 Double-Adjustable shock absorber. Image:

CHpg Staff. |

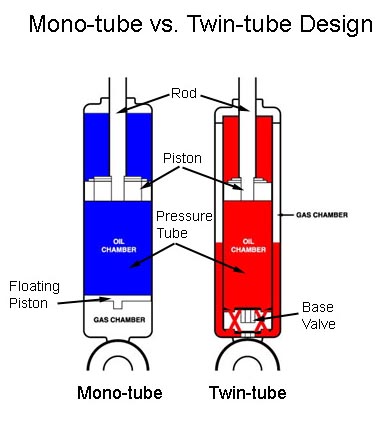

In

the past, the shocks we've used have been "monotube" gas

shocks, however, QA1's are twin-tube gas shocks.

Both monotube and twin-tube designs use gas pressure to

inhibit the shock oil's tendency to foam during severe

duty. Monotube shocks use an inert gas at relatively

high pressure on the opposite side of a floating piston

to keep a constant volume of oil in the shock body as

the piston adds and subtracts volume when it moves. To

achieve the same end, twin tube shocks use inert gas at

a lower pressure inside a flexible containment envelope

or "bag" located between the inner and outer shock

tubes.

|

|

|

Image: QA1 Motorsports. |

One

drawback of high-pressure monotube shocks is the gas

pressure. Let's say the shock is pressurized to 80 psi

and has a piston area of 3.1 sqin. That adds 250-lbs to

the spring rate on compression. As Roger Wilson, QA1

Motorsports' Sales Manager told us, "This causes the

nose of the car to push upward going over a rise or bump

at road speed rather than the vehicle following the

contour of the road as much as possible. The QA1 gas

bagging method exerts no rod or piston pressure as the

shock begins its rebound stroke so the vehicle nose more

closely follows the road, which enlarges the tire

contact patch and enhances control characteristics."

"The

shock adjustments control the amount of fluid which

passes through the base of the shock." Wilson

continued. "Damping authority increases as the

adjustment valve is closed. A single adjustable model

increases or decreases rebound and compression

simultaneously as the knob is turned clockwise or

counterclockwise. A double adjustable model separates

the rebound and compression adjustment and allows

adjusting the shock from, say, a 90/10 to virtually just

the opposite.

"The advantage of a double adjustable is the enormous

versatility–from

a competition-ready drag shock to a shock with a level

of control appropriate for road racing or autocrossing

and to even a smooth, controlled ride for daily driving–available

from the same shock."

Some

believe aluminum-bodied shocks are not as durable in a

street application as are more common, steel-bodied

shocks, however, QA1 Motorsports uses 6061 aluminum

heat-treated to the T6 specification and shock pistons

having bronze-impregnated Teflon sealing bands. Both

features make a QA1 shock quite long-lasting.

Additionally, the twin-tube design is less vulnerable to

external damage which would render a steel monotube

shock unusable.

For

the chassis mods in this part of our series, Global West

volunteered its installation work at its facility in San

Bernardino, California. First Global's guys removed the

rear springs, shocks and track bar. Eighteen months ago,

for Part Four of this series, we installed GW's Track

Bar Kit and noted an improvement in the car's handing,

especially on corner exits.

Since then, Global West developed an Upgrade to its

Track Bar which makes it even stronger and more

adjustable. Global West upgraded us to the new design

(PN PHC-32K) which further stiffens the track bar

mountings and adds three height adjustments which enable

the user to tune corner exit traction. Whereas the basic

Global West Track Bar is a bolt on, this Upgrade is not.

Extensions have to be welded to the track bar brackets

on the underbody structure and on the rear axle.

Global's Eric Norrdin did that work for us.

|

|

|

Installation of Global West's Track Bar upgrade

requires accurate positioning of the parts prior to

welding. Eric Norrdin used an angle measuring device to

make sure the bracket to be welded to the rear axle will

be perpendicular to the ground. Image: CHpg Staff.

|

|

|

An intermediate level of arc welding experience

is required to install the Track Bar upgrade's brackets.

A wire-fed welder makes the process easier. Image: CHpg

Staff

|

|

|

The upgrade includes this brace which reinforces

rear axle track bar mount. Image: CHpg Staff. |

|

|

|

On the other side of the car, part of the stock

bracket is cut off. The new bracket will be welded

in place of the material removed. Image: CHpg Staff. |

|

|

|

The Global West Track Bar body mount is

a more robust structure necessary reduce deflection of

the underbody structure under loads applied by the

Track Bar to the vehicle structure during hard

cornering. It also is required for the height

adjustment. Image: CHpg Staff.

|

|

|

|

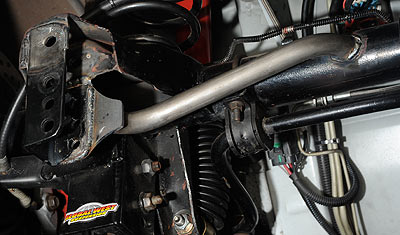

Also part of

the upgrade is a stronger track bar

bracket brace made of 1.250 diameter,

0.125-wall thickness, DOM, mild, tubular

steel. This stout piece bolts into the

stock brace mountings on the left and to

the newly fabricated mount on the right.

The more robust mounting brackets,

heavier brace and beefy Track Bar make

the Global West Track Bar system far

stronger than OE parts. Image: CHpg

Staff. |

|

|

|

|

While

variable rate springs used by GM and

some aftermarket suppliers offer

improved ride when the car is lightly

loaded, a constant rate Global West

spring offers more consistent handling

balance when the car is driven hard near

its cornering limits and better control

of the rear axle under hard

acceleration.

Image: CHpg Staff. |

|

Global West folks installed a pair their

rear springs (PN SA40) which are unique in

the industry for having three coils right at

the top which are wound in coil bind. This

gives the user a way to cut the spring to

adjust ride height without changing the

spring rate. A Global West rear spring can

be cut as much as three inches without

changing its rate. Global's owner, Doug

Norrdin, test-fitted our rear springs, then

cut 1.5 coils off them and reinstalled them.

Our rear ride height is virtually the same

as before. Next to go on were the QA1 rear

shocks. Doug, installed them and set them

with a baseline adjustment of : 4-clicks,

compression, and 6-clicks, rebound.

|

|

|

The best way to shorten a coil spring is with a

cut-off wheel. Here, Global's Doug Norrdin shortens one

of our rear springs a coil-and-a-half. Norrdin's

experience shows as that was the perfect length for the

ideal rear ride height of a car in a street performance

duty-cycle. Image: CHpg Staff.

|

|

|

|

|

With the Track Bar brackets and brace installed

and the rear springs cut to the correct length, the next

steps were to install the upper spring seats, the

springs and reinstall the Track Bar. Image: CHpg Staff.

|

|

|

|

|

The installation of the QA1 double-adjustable

shocks is the same as a stock item. Before putting them

in place, Doug Norrdin set their adjustments at 4C6R.

Once they are on the car, the adjustment is as simple as

jacking up the back, supporting it safely then turning

the knobs at the bottom of the shock. Image: CHpg Staff. |

|

|

|

|

The final rear suspension task was to

center the body using the Track Bar's

length adjustment. Global West uses a tool they built

which indexes off the wheel rather than the tire making

the adjustment more accurate. |

|

|

|

One of the weaknesses of

the 4th Gen Camaro front suspension is

the rear bushing in the front lower

control arms. They have a short service

life on cars capable of high lateral

grip and which are driven hard. In our

case this was our second set which went

five years and a little less than 50,000

miles. GM no longer services the

high-performance 1LE bushings, but Moog

sells the same part in its bushing kit (PN

K6490). We ordered two kits from

RockAuto.com and replaced the rear

bushings in both arms. Image: CHpg

Staff. |

|

|

|

The next step was to remove and

disassemble the front shock/spring assembly. If you do

this yourself, make sure you use the proper spring

compressors. Failing to do so risks injury or death if

the shock/spring unit is disassembled improperly. Image:

CHpg Staff.

|

To

assemble the front coil-overs, Eric Norrdin began by

installing a QA1 Torrington bearing on each front

shock's adjuster ring followed by an Eibach 600-lb/in

spring, a spacer and a low-rate Eibach "helper" spring

which keeps the main spring on its seat when the

suspension is at or near full rebound. Next, to go on

was a QA1 compression stop (PN BC01) which may be needed

in some street application because QA1s for coil-over

applications do not have stops. The BC01, must be cut to

fit. The top three sections are removed and what's left

is installed in the shock.

|

|

|

Assembling a true coilover is much easier than

doing the stock shock/spring combos because neither

specific "clocking" of the parts, discussed in the

Factory Service Manual, nor spring compressors are

required. Image: CHpg Staff.

|

|

|

|

A key part of the front coilovers is Global

West's spring seat adapters–the

cast aluminum piece between the helper spring and the

stock upper mount–which

ensure the durability of the costly upper spring mounts.

Image: CHpg Staff. |

|

|

|

Installing the Eibach/QA1 coil overs is a little

easier because they are slightly less in diameter and

are lighter.

Image: CHpg Staff. |

|

Eric

then added Global West Spring Seat Adapters, a key part

of the front shock build-up as it vastly improves the

durability of the front shock mounts. The design of 4th

Gen F-car front upper spring mount has the majority of

suspension load applied by the spring to the rubber

upper mount through a spring seat molded into the mount.

Only damping loads are applied to the upper shock mount

which is concentric with the spring seat. Some

aftermarket coil-over conversions for 4-gen Camaros

apply all load through the upper shock mount. They do

this because it simplifies the design and reduces cost,

however, concentrating all the load on the smaller shock

mount, causes the upper mount to wear rapidly–not

good when you consider upper mounts are over $200 each.

Global West's spring seat adapter is a cast aluminum

piece which goes between the Eibach spring and the stock

spring mount and insures suspension loads are applied to

the upper mount in the way GM intended and that

preserves the part’s

durability.

|

|

|

Our road-ready, front suspension and brakes.

Image: CHpg Staff.

|

After assembling the Global West front coil-overs, Eric

set our baseline spring height adjustment at six-inches

from the bottom of the threads on the shock body to the

spring adjuster ring then put them on the car.

|

|

|

The revised THRS rear suspension showing the

Global West Track Bar Upgrade.

Image: CHpg Staff. |

|

|

|

If you have to adjust the rear shocks, this is

what you see once you've got the car safely in the air.

Simply turn the knobs to change damping authority. The

knobs turn valves which have strong detents, so there's

no confusion about how many clicks you've turned. Image:

CHpg Staff. |

With

the Track Bar upgraded and the new springs and shocks in

place, Eric Norrdin began the final chassis modification

for this part of the THRS series: installing a set of

Global West Subframe Connectors (PN 905). The purpose of

adding subframe connectors to a unit-body car is to

increase the strength of its underbody structure which

can flex in two ways. It can bend longitudinally or it

can twist. When the aftermarket invented subframe

connector (SFC) kits, it was drag racers who lead the

way and many of the cars for which connectors were

designed had the main subframe rails inboard from

channel sections which underlie the car's rocker panels.

Consequently, some subframe kits link the inboard rails.

That makes an improvement to the car's stiffness in

bending–which

is great for drag racing–but

not so much to stiffness in torsion because the greatest

torsional deflection comes at the outer parts of the

structure.

|

|

Global West's Subframe Connector kit for 4th Gen

F-cars. Image: Global West Suspension.

|

Other makers of subframe connectors for 4th Gen Camaros,

Global West included, tuck them into the cavity between

the rocker panel and the pinch weld which runs the

length of the car between the wheels. Such an

installation stiffens the car both in bending and

torsion and stiffness in torsion is important to a car's

limit handing, especially when the car is modified for

increased lateral grip and additional roll stiffness.

|

|

The Subframe Connectors are not a bolt-on part.

They must be welded onto the car by an experienced

fabricator.

Image: CHpg Staff. |

A

proper subframe connector installation cannot be done

with bolts. Global West's SFCs must be welded in place.

One final aspect of subframe connector installations is

an issue enthusiasts usually don’t

consider. The connectors we installed are made from

0.125-in wall thickness, drawn-over-mandrel (DOM), 1020

mild steel tubing. That extra structure under the doors

is a significant enhancement to the car's side-impact

crashworthiness.

|

|

After all the work at

Global West, it was time for the crowing

touch, suspension alignment. Global uses

a Hofmann, optical-sensing alignment

system. "Targets" are attached to each

wheel and light sensing devices measure

alignment using the white dots on each

target board. Seems a little "wizbang" at first, but the system

is dead nuts accurate. Image: CHpg Staff. |

|

|

|

Eric Norrdin at the controls of the Hofmann rig.

The unit's computer displays caster, camber and toe

information. Image: CHpg Staff.

|

The

final task at Global West work was to 1) verify the ride

height–Eric's

initial adjustment was spot on–then,

2) do a front end alignment to our specs which are: -0.5°

camber, 4.5°

caster and 3/32-in toe in. |

|

|

Another tool we used a lot since we got it last

year is this Matco impact gun or, more properly the

"1/2-in Quiet Air Impact Wrench" (PN MT1769QA). We like

this tool because it's much quieter to use than the air

impact we had before. The grip and the back half of the

Matco are composite plastic and the hammer case and all

reciprocating or rotating parts are metal. The Matco

weighs 4.1-pounds, about six and half ounces less than

impact we had in the shop before. Almost half pound

makes quite a difference in the feel and handing of the

tool. The MT1769QA is one of the most powerful 1/2-drive

impacts Matco makes and are among the most powerful in

the industry. Its nominal torque range is 50-650 ft/lbs

and maximum rated torque is 780 ft/lbs. To go with our

new impact, we ordered two sets of Matco's nearly

indestructible impact sockets, metric and SAE. Image:

CHpg Staff. |

Click for Page 3

->

|