|

Building the Tom

Henry RS

Part Six: Service, Seating, Tuning, an SS Hood and

Nitrous Oxide End the Project

by Hib Halverson

|

|

|

Image: CHpg Staff. |

We begin this final

part of the Tom Henry RS project with how we solved a

brake problem and how we found out later it was

self-inflicted. For most of this project, the Camaro's

brakes have been stock calipers with upgraded brake

rotors from Baer Brake Systems.

|

|

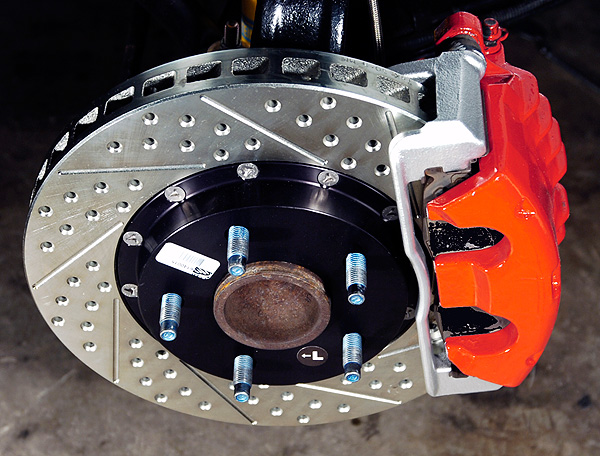

The THRS

front brakes uses drilled and slotted Baer two-piece

rotors and stock calipers. Image: CHpg Staff.

|

|

In the run up to this

part of the THRS series, we started feeling brake

shudder during braking from highway speeds and the

problem became progressively worse. Thinking this was a

thickness variation or runout problem, we measured both.

Turns out, we were wrong. Our Baer rotors were within

factory limits for thickness variation and runout.

Further road testing

demonstrated that, at slow speeds, just before the car

came to a stop, the shudder's frequency became low

enough that we could feel a back-and-forth sort of

"rocking motion". We pulled the rotors and inspected

them carefully. We saw sections of gray mixed with

sections of normal surface appearance. Deciding this was

a problem with transfer of brake pad material to

sections of the rotor and thinking we could remove it

with abrasives, we abraded them using an air grinder

fitted with coarse, non-woven, metal finishing discs

from Standard Abrasives. That didn't have much of an

effect and the brakes still shuddered.

We had several

conversations with Rick Pojman, the Customer Service rep

at Baer Brake Systems. He said that uneven transfer of

pad material to the rotor surface can be caused either

by brake pads which were not properly bedded or by pads

which have been overheated. If the problem was

overheating, we had made the wrong choice in pads and a

more aggressive pad might be necessary.

|

|

A benchmark of the

service trade for IR thermometers is this Raytek

ST-25. The one in our toolbox is ten years old and has

been indispensable when we need to measure temperatures

of various parts on a car. Image: Raytek Corporation. |

|

We needed to take

some brake temperature information before we could

decide whether or not we were going to change to a

different brake pad. We drove up into some nearby

mountains then came back down the same curvy road.

Several different times we stopped in a safe spot and

shot one of the front rotors with our Raytek ST-2 Autopro infrared thermometer. The highest temperature we

recorded was 519°F. Given that we never exceeded 80-mph

and, because most of the braking areas were at the end

of straights, the brakes were cooling between

applications; we figured our peak brake temp was higher.

We also noted that the brake shudder problem had become

much worse. After our brake temp testing session, back

at the shop, we pulled all the brake rotors again.

Looking at the

fronts, it was obvious that the problem with pad

material transferring to the rotors was more serious

than before. That along with our temperature readings

had us believing our problem was that we were exceeding

the design envelope of the brake pads.

|

We contacted Baer's

customer service agin, this time asking advice on what

to do with our rotors. The always-helpful, Rick Pojamn

said that a temporarily switch to a racing pad will wipe

the transfer away. He added that the only surefire ways

to fix the problem are either to machine the rotors or

replace them.

Machining works well

provided the rotors has minimal wear, the brake lathe

operator knows how to apply the proper final finish and

the amount of machining required is .005-in. or less. If

the rotors are close to or below minimum thickness,

rotor replacement is your only choice.

|

|

|

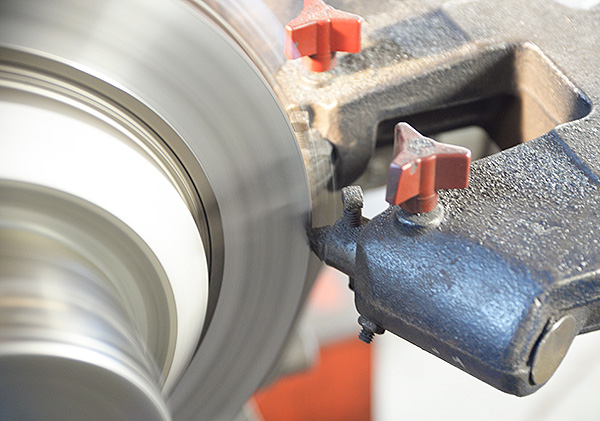

Since the Baer rotors

had only minimal decrease in thickness, we decided to

fix the pad transfer problem by having the rotors

machined just enough to remove the coating of pad

material. Image: CHpg Staff.

|

Our solution was

two-fold. First, we took the rotors to Bob Woolever's

Tire Shoppe and had Bob machine the rotors just enough

to remove the pad material. This amounted to about a

.005-in. thickness reduction and left us well over their

minimum thickness specifications.

Next, we dialed up

Porterfield Enterprises, a specialist in

high-performance street and racing brake pads. The

company was started in the mid-'80s by the late Andy

Porterfield, a semi-professional road racer who spent

most of his career driving Camaros and Corvettes in the

SCCA Trans-Am, GT-1 and various "outlaw" road racing

series on the West Coast. In 1986 he became the U.S.

distributor for Ferrodo racing brake pads and, in the

near 30 years since then, Porterfield Enterprises has

become the go-to source for racing brake pads in the

U.S. Porterfield is the only vendor which sells

Raybestos racing brake pads to consumers.

|

|

|

The difference

between street pads (left) and racing pads can be seen

in the texture of the pad material. Also, the Raybestos pads (right) for the rear are only

available in a C5 Corvette pad which fits the '98-'02

Camaro rear caliper but requires the pad abutment shims

be deleted. That can cause some occasional rattling.

Image: CHpg Staff.

|

After talking with

Porterfield's, Tim Gray, we decided to try a set of pads

made with Raybestos ST-43 compound. Raybestos terms this

a full race pad compound but it can be used on a road

car if one is willing to accept a bit higher pedal

effort when the brakes are cold, some brake noise and

quite a bit more brake dust than is emitted by stock

pads or even some "performance street" pads.

Additionally, these pads are harder on rotors. If you

don't like brakes squeaking and dusting or you want

rotor life the same as stock; don't use this brake pad,

however, if you want brakes that really work well and

are willing to replace rotors more often, the ST-43 is

the way to go.

There are also a

couple of "alternative fit" issues with these pads.

First, they don't have the stock GM wear indicators

which "screech" when the pads are near gone so use of

them requires occasional brake pad checks. Secondly, the

rear pads, while they fit Camaro rear calipers, are

actually a C5 Corvette pad. Corvette rear pads have

three locating tabs on their backing plates. If you

install the calipers and caliper mounting brackets as a

unit, there is no installation issues, however, if you

change pads by simply removing the caliper from the

caliper mounting bracket, you have to put the pads into

the grooves in the mounting bracket then carefully work

the caliper over the locating tabs. Doing that is a bit

awkward but patience and care will get you through the

process.

|

|

|

We cleaned up the

parts with a little Simple Green Motorsports Degreaser

then installed the Raybestos pads. Image: CHpg

Staff.

|

So far the ST-43s are

working well with no signs of brake shudder and–holy

crap–do they stop! When we hit the brakes, the

Porterfield/Raybestos pads really bite hard, stop quick

and don't fade.

|

|

|

Braking

performance was markedly improved. We've run the Raybestos pads we got from Porterfield Brakes for

several months and, so far, no signs of brake shudder.

|

Oil Change and Oil

Leaks

Because we're going

to put the car back on the chassis dyno later in this

article, and it's been quite a while since we changed

the oil in the THRS's engine, we got the car up in the

air, drained the crankcase then pulled the filter off.

In went five quarts of fresh Red Line 10W30 Engine Oil.

Next, we prefilled a new ACDelco UPF52 Ultragard Gold

oil filter and screwed it in place. If you've followed

this project from the start, you know we've used nothing

but Red Line 10W30 in our mod'ed three-eight.

|

|

|

ACDelco's

Ultragard Gold is GM's premium aftermarket oil filter.

We use the UPF52 which not only is an upgrade over

regular ACD "Duragard" design but also is a longer

filter than the PF47 which is stock on a 3.8. Normally,

'52s are used on trucks. We've been using Red Line 10W30

engine oil in the Tom Henry RS engine since the car was

new. Image: CHpg Staff. |

There are two main

reasons for that. First, we prefer Red Line's robust

base stock combination of esters and polyalphaolefins

(PAO) and the better performance and protection at high

oil temperatures they provide. The Tom Henry RS doesn't

have an engine oil cooler and we're making 50% more

power than stock which means, when we're running the

engine hard for sustained periods–say we take a sporting

run over one of our favorite twisty roads–we see as much

as 260°F oil temperature. We use an AutoMeter Sport-Comp

II electric temperature gauge (PN 3656) and its sensor

is in the oil filter housing, perhaps the coolest place

in the oiling system. If we have 260° at the oil filter,

the oil may be 280° in bearings. Under that kind of

abuse, the margin of safety offered by Red Line's

thermal stability is desirable.

Second, we can run

Red Line 10W30 to extended drain intervals as a way of

recovering some of the oil's higher cost . Since the

1000 mile mark, the V6 in our Camaro has used Red Line

and oil changes have been done every 18,000-20,000 miles

with a filter change every 4000-5000 miles. We have over

a dozen years of spectrographic oil analysis data to

back up our advocacy of Red Line and extended drain

intervals.

The car's Tremec T-5

five-speed manual transmission has been in service just

under 120,000 miles and lately, we noted it has been

weeping lubricant out of its rear seal. When we grabbed

the driveshaft and pushed it up and pulled down, we

could see the lip of the rear seal was deforming too

much, indicating that the extension housing bushing was

probably worn out. Considering how hard we've beat on

the trans in this car, even Red Line MTL's superior

lubrication couldn't make that bushing last more than

120K.

Tom Henry Racing's

Parts Manager, Stan Lorence, told us GM does not service

the bushing. You have to buy the whole housing to get

it. The cost? Take a deep breath–630 bucks. We about had

kittens when we heard the number.

We started looking on

the aftermarket for the bushing. A session with Bing

found one at

Manualtransmissionparts.com

in Alabama so we ordered the bushing (PN 44066) along

with a rear seal from Tom Henry Racing.

|

|

|

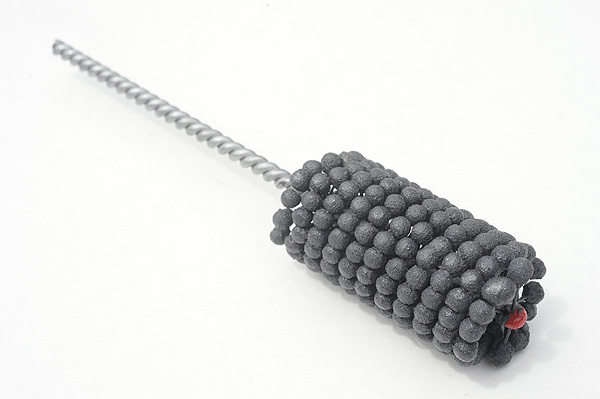

We didn't expect the extension housing

bushing we bought to be "hone-to-fit"

but it was. Initially, we could not

install the driveshaft into the

transmission, so we had to get the

housing off a second time and hone the

bushing with a Brush Research

"Flex-Hone". Image: CHpg Staff. |

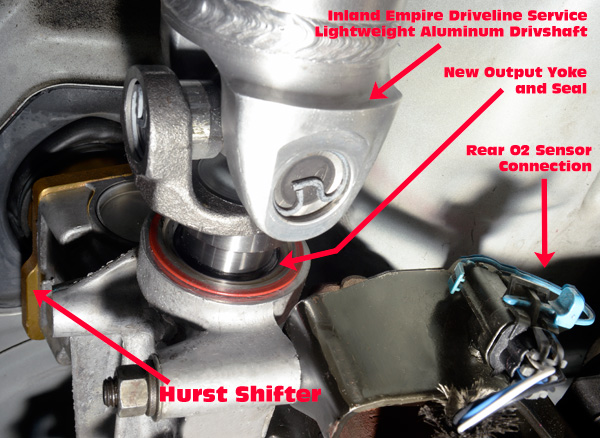

With the car up on

stands, we removed the gearbox, unbolted its extension

housing then, took it to a nearby automotive machine

shop which had a hydraulic press and had them change the

bushing. Back at our shop, we honed the bushing's inside

diameter with a 1.375-in. 240-grit Flex-Hone (PN

BC13824) to fit the output yoke on our Inland Empire

Driveline Service aluminum drive shaft, wiped some Red

Line Assembly lube in the I.D. of the bushing and

reassembled the trans.

Since we had the

trans out and its clutch release bearing assembly was

ten years old, we replaced it with a new unit (PN

24264182) from Tom Henry Racing. We put the trans back

in, reinstalled all the brackets and mounts. We wiped

some more Red Line Assembly Lube on the O.D. of the

yoke, then reinstalled our EDS aluminum shaft.

|

|

|

Worm's eye view of

the back of the transmission. When the

extension housing bushing is worn, the

driveshaft front yoke can "wobble" on

the output shaft splines. Once the end of

the yoke moves a distance greater than the seal's lip

can expand, it starts to leak. Image: CHpg Staff. |

We filled our T-5

with "MTL" which stands for "manual transmission

lubricant", Red Line Oil's low-viscosity, GL-4 gear

lubricant. MTL is a performance upgrade over the ATF

which most people use in T-5s and a better choice for

severe duty, such as transmissions behind modified

engines in street high-performance or racing

applications. It's GL-4 rating means it's formulated

specifically for lubricating spur gear or helical gear

transmissions. It's, also, blended to have just the

right friction coefficient for optimal performance of

cone-type synchronizers. While it's rated 75W80 on the

gear lubricant viscosity scale and 5W30 on the engine

oil scale, both of which are somewhat higher viscosity

than ATF; MTL still is a low-vis trans lube like GM's

"Synchromesh" or "Manual Transaxle" lubricants. Red Line

MTL has good low-temperature shift feel,

high-temperature stability and overall lower shift

effort.

|

|

|

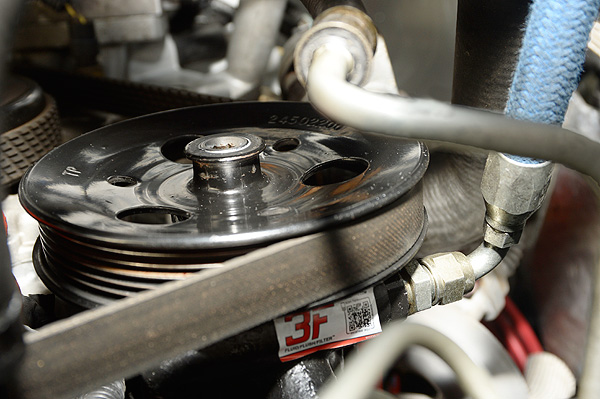

Worm’s eye view of the power steering pump. It looks

hard to change but, as long as you have pulley removal

and installation tools, changing it is pretty easy. The

key task in the pump change is vacuum bleeding the

system once the pump is installed. Image: CHpg Staff

|

The five-speed

was not the only thing leaking. During our work under

the car to R&R the transmission, we noted the power

steering pump was weeping fluid, too. Like the cost of

the tail housing, the cost of a new steering pump was

over-the-top, so we ordered an A-1 Cardone

remanufactured pump from Rockauto.com (PN 20905). We

like Cardone’s reman parts and, when we get them from

Rockauto.com the price is competitive and the service is

quick.

The pump replacement

was straight forward. We used a Bosch Automotive power

steering pump pulley removal tool (PN J-25034-C) to get

the pulley off, disconnected the hoses then unbolted the

pump. Putting the

Rockauto.com

reman in place was, the reverse of removal. With the new

pump in place, we used another tool (PN J-25033-C) to

reinstall the pulley. Finally, we filled the pump

reservoir with Red Line Synthetic Power Steering Fluid.

Again, we choose Red Line because it's a better for high

performance use than the ordinary petroleum-based

fluids. We bled the air out of the steering system per

the Service Manual's instructions using a tool we made

from a bathtub stopper.

|

|

|

Our Bosch

Automotive power steering tools. At

right is the pulley removal tool. At

left is the installer. Image: CHpg Staff. |

Lastly, we had a

leaking rear axle shaft seal on the right side so, we

dropped the rear axle cover, removed the axles and

replaced the axle seals on both sides with parts we

ordered from the Tom Henry Racing parts department.

|

|

|

The Fikse

Profil 5 in 17x9-inch size. These wheels have been on

the car for eight years. They look almost as good now as

they did when they were installed in 2006. Image: CHpg

Staff.

|

Round and Black

Several years ago, we

put Fikse Profil 5S wheels on the Tom Henry RS. Because,

Fikses are so light for a street wheel, we were able to

go from a 16x8 to a 17x9.5 yet not increase unsprung

weight. We expected this, considering their racing

pedigree. Cars on Fikses have won both the World's

preeminent endurance races, the 24 Hours of Daytona (4

times!) and the 24 Hours of LeMans.

The Fikse Profil 5S

is a modular design with a rotary-forged, CNC-machined,

clear powder-coated, aluminum center. The rims are

forged, heat-treated aluminum. "TechniPolish" is Fikse‘s

standard finish and features a robust, liquid-cured,

clearcoat on the diamond-turned center section. The

mirror-polished rims are left uncoated to allow for

touch-ups as needed in case of minor scrapes.

|

|

|

Shown here during the

tire's press introduction in the summer of 2000, the

Goodyear F1 Supercar was designed for the C5 Corvette

Z06.

Image: CHpg Staff.

|

The wheel change

allowed us a significant tire improvement: the

265/40ZR17 Goodyear F1 Supercar. The Supercar was

engineered specifically for the C5 Corvette Z06 of the

early-'00s, but Goodyear's design has held up well and

is still a good choice in ultra-performance summer tires

of that size. It is one of a few tires which bridges the

gap between all-round, performance tires, such as the

Goodyear F1 GS-D3, which we used when we had 16s on the

car, and DOT-approved, radial road race tires which are

not acceptable for general street use because of short

tread life and almost nonexistent, wet traction. While

the F1 Supercar is more sticky than some other tires

that size, it's not the drag race tire that a "drag

radial" from Goodrich, Nitto or Goodyear might be.

Nevertheless, the Supercar makes a great "compromise"

tire which performs well in a variety of street

performance situations other than heavy rain or freezing

weather.

|

|

|

The outside

of the F1 SC has large, stiff tread blocks and reduce

tread depth. The stiffer the tread and the more shallow

the grooves, the less the tire's contact patch "squirms"

and the better the tire handles. The smaller blocks and

wider grooves in the inside of the tread give the

Supercar acceptable performance if we get caught on a

wet road. Image: Goodyear Tire and Rubber Co.

|

|

|

|

This drawing

illustrates what's under the tread of a

F1 Supercar. The wedge, spiral-wound

overlay and the steel belts contribute

to the tire's performance. Image:

Goodyear Tire and Rubber Co. |

The main advantages

to the Tom Henry RS with the F1 Supercars are improved

at-limit handling due to more traction coming from a

wider tread, more aggressive rubber compound, slightly

reduced tread depth and a tread block design skewed

towards handling. Additionally, the F1 Supercar casing

design improves steering feel and yaw response.

One characteristic of

the F1 Supercar has surprised us and that's tread life.

We ran them on the car for seven years, putting them on

in the early Spring, Summer and Fall and taking them off

during the Winter. When that first set of Supercars was

down to the wear indicating bars, there was no question

as to our replacement choice. We had Tom Henry Racing's

Stan Lorence order another set of Goodyear F1 Supercars.

|

|

|

Though the F1

Supercar's design is a bit dated, in the 17-inch size we

use on the Tom Henry RS, it provides very good lateral

grip as shown there in testing during the suspension

work we did for Part 5. Image: CHpg Staff.

|

Inside Improvements

Now, for some

interior upgrades. First thing was to fix the car's

nasty-looking steering wheel. Most V6 Camaros have the

base wheel, a simple, rubber-covered unit. On the upper

(where you put your hands) and lower (where your knees

slide under it) parts of the wheel, the smooth black

surface of the rubber had worn away exposing a

ugly-looking and rough-feeling, dark gray, sponge-like

material.

We contacted two

companies which advertise late model steering wheel

repair and restoration: Mike's Custom Steering in

Kentucky and Dallas Custom Steering Wheel in Texas. Both

were unwilling to refurbish the THRS's stock steering

wheel at any price.

|

|

|

After 13

years of use, the car's steering wheel–mainly the top

1/3–had worn severely.

Image: CHpg Staff.

|

Our next idea was to

look for a new or used steering wheel. As for new–no

way. Tom Henry Racing's Parts Manager, Stan Lorence,

told us they're long since discontinued and no dealer in

the country has any "new old stock". As for used

units?Turns out, wheels for fourth-gen base cars in good

condition are difficult to find. We saw several on eBay,

but all were wearing the same way as ours.

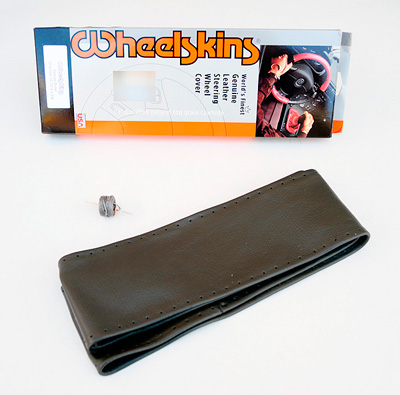

We decided to install

a leather rim cover, manufactured by Wheelskins, on the

existing ugly wheel. Wheelskins are made of top-quality

cowhide produced in the U.S. and can be had in a number

of colors. The lacing is made from a nylon material

similar to that used in "parachute cord" and is waxed to

make the lacing process easier.

|

|

|

Our solution was a Wheelskin kit. It comes with everything needed to

recover the wheel.

Image: CHpg Staff.

|

A Wheelskin is

installed by stretching it around the rim of the wheel

then taking the lacing tool–a large, dull-tipped needle

included with the product–and the nylon cord and lacing

the cover's sides together. The holes for the cord are

already punched in the leather.

|

|

|

While the big

needle used to thread the Wheelskin's lacing is not

really sharp, it's easier on the fingers if you have a

mechanic's glove on the hand that holds the needle.

Image: CHpg Staff. |

Installing the

Wheelskin is easy work but tedious. The instructions

suggest installation takes an hour but, for someone

who's never done a Wheekskin before–that's us–it's more

like three hours, working slowly and following the

instructions to the letter.

|

|

|

Once the Wheelskin was in place, the THRS Camaro's steering wheel

looked and felt much better. Image: CHpg Staff.

|

When we were done,

the steering wheel in the THRS looked great and felt

much better in our hands than did the original rubber

covering, even when it was new. Another feature of the

Wheelskin treatment we liked is that it increased the

diameter of the wheel rim by about a 1/16 of an inch

which doesn't seem like much but it contributed to the

steering wheel feeling more substantial. Two thumbs up

for the Wheelskin because, literally–as when one's hands

are positioned correctly on the wheel, both thumbs point

up–and figuratively as we really like this product.

The next step was to

do something about the car's seats. The stock seats'

lack of side support was our main problem. We tried two

solutions. The first, our "quick-and-cheap" solution was

to remove the driver seat and have a local upholstery

shop increase the amount of padding on the edges of the

back and the cushion and recover the seat. It had the

effect of letting the driver settle deeper into the

cushion and back, thus increasing side support.

Considering the low cost, this was a great modification.

"Stage Two" of our

seating program was to replace the stock seats with a

pair of Scat Enterprises Procar "Rave" seats (PN

80-1600-64L and 80-1600-64R). which are an affordable,

"weekend warrior" grade of racing seat with the added

convenience of a reclining back.

|

|

|

The Procar

seat installation begins with the adapter bolting to the

stock seat mounting holes. Image: CHpg Staff. |

Procar Raves are

installed using a set of Scat's adapter brackets (PN

811068, left, and PN 811069, right) which are specific

to the 4th gen cars. You're supposed to remove the stock

seats, bolt the brackets to the stock seat mounting

holes then install the seats onto the brackets.

|

|

|

This shows the one

problem we had with the installation:

the mounting system needing to be

modified because of clearance problems.

The mod was cutting the lower two holes

of the front of each seat track.

Image: CHpg Staff. |

Unfortunately, it

wasn't that easy. In theory, Procar's method of fitting

a single seat design to a wide variety of cars is pretty

slick. In practice, it didn't work well on our Camaro.

The mounting tabs on the seats have three holes,

intended to give the installer a choice of height or

rake depending on which holes are used to bolt the seat

to the adapter bracket. During our test fit, we couldn't

get the seat low enough because the front mounting tabs

bottomed on the floor of the car before their uppermost

holes, which provide the lowest mounting height,

lined-up with the holes in the bracket. The seat was

tilted back too far and the front was too high. The

solution? A cutting wheel on our air grinder with which

we removed most of the front mounting tabs. Once we did

that, the Rave bolted in and the seat rake was better.

|

|

|

These

seats were priced right, looked great

and had the side support typical of a

racing seat, but in our tests, they

didn't work well for people with small

butts and short legs. Image: CHpg Staff. |

We road tested the

Raves for several weeks. The increase in lateral support

over our modified stock seats was significant. Lumbar

support was better, too. A downside was the cavity in

the seat cushion was too long for someone with shorter

legs. With my butt against the seat back, I had to move

the seat forward to reach the pedals. If I sat with

front of the seat supporting my calves, there was a big

gap between my butt and the seat back. Folks with longer

legs probably would enjoy the Raves more that we did.

In other interior news, right in the middle of getting

this article together, the driver side window on the Tom

Henry RS quit working. After diagnosing the problem,

it's obvious to us that, If your Camaro is high

mileage–like the Tom Henry RS is at 120,000 miles–it's

not "if" but "when" the side window mechanism will fail.

This is because there is

a durability problem with the window sash channel which

to which the side glass is attached. At either end of

this channel are brackets to which the glass is attached

with blind or "pop" rivets. The rear bracket also holds

the axle for the roller which runs in the vertical

window lift channel. When the widow is moving down and

this roller gets to the bottom of the vertical channel

it hits a stop. The force of the roller pushing

against the stop causes the axle to be forced sideways

and that causes the sash channel rear bracket to flex.

Over a period of time, that flexing eventually cracks

the bracket and the crack grows until either the axle

falls out or the section of the rear bracket holding the

axle breaks off. Once that happens the window lift

fails.

The pop rivets holding

the glass to the sash channel are not the typical

aluminum type with which most DIYs are familiar. They

are made of steel and require a long-handled, commercial

grade rivet "gun". In fact, at the assembly plant, the

window glass was riveted to the channel brackets with

an industrial-type, power-operated rivet gun. Most DIYs

are not going to have access to a factory-type rivet gun

and even the manually-operated, long-handled commercial

guns are not going to be a tool to which most DIYs have

access.

I ran into this riveting

problem with the THRS when the driver side window

mechanism quit working. I disassembled the door, noted

that the rear sash channel bracket had broken. I found

the axle at the bottom of the door. To repair or replace

the sash channel, you have to remove the glass, first

and to do that, you must drill out the rivets. Once you

do that, you can replace the sash channel. Once the new

sash channel in in place, the Factory Service Manual

says to replace the rivets with new units from GM.

Problem was, no way did I own a pop rivet gun which

could install steel rivets.

|

|

|

This glass sash

channel stud was used on all 2nd gen

cars. GM could have kept using it on the

3rd and 4th gen cars, but, in the

interest of quicker assembly, switched

to rivets. Obviously, they decided not

to allow easy service which is kinda

stupid considering side glass

replacement is not an unusual need.

Image: Year One, Inc. |

My solution? Oldskool.

The '67-'81 Camaros and Firebirds used bolts and large

"washer/nuts" rather than rivets to hold the glass to

the sash channel. It was very simple to order three door

glass sash mount stud assemblies (PN598) from Year One,

discard the large washer nuts and replace them

with smaller, conventional 1/4-in. flat washers and

1/4-in. self-locking nuts then use that set-up to

attach the glass to the sash. That was much easier

than trying to find a tool to install new blind rivets.

|

|

|

This is

how the installation looks once the stud

is in place. You have to supply your own

1/4-in. flat washer and self-locking nut

both of which are easily to find at any

hardware store. For comparison, the

washer/nut which comes with the stud is

shown. That part you discard. Image:

Author. |

Once I had the parts order from Year One, I had my

driver side door back together in about an hour. The

window mechanism works great. The sash mount studs can

be found at

https://www.yearone.com/Product/1967-81-camaro/sm598

Getting with the

Program

|

|

|

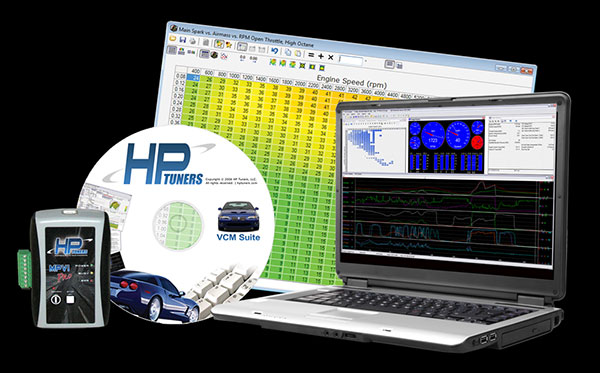

The VCM Suite

configuration we picked was the GM base and the uplevel

MVPI Pro. Among other features, the MPVI Pro differs

from the base model in that it has the hardware you need

to bring a wide-band oxygen sensor signal into VCM

Scanner so you can have wideband data. Image: HPTuners

|

Reprogramming the

calibration of our V6's ECM was required because of the

extent of its modifications–Comp cam, Mark DeGroff

ported/polished/cc'ed heads with bigger valves, Katech

valve springs and titanium retainers, Yella Terra 1.8:1

rockers, Extrude Honed intake manifold, Whisper Lid,

headers, MSD coils, Denso IT-20 plugs and a Flowmaster

exhaust.

We started reworking

the THRS calibration in Part 5 and we finished it for

this final installment of the series. We work with

HPTuners' “VCM Suite” software, which we ordered from

Summit Racing Equipment because the price was

competitive and Summit turns around orders quickly. VCM

Suite includes “VCM Editor,” an application for

calibrating 1997 or later GM vehicles, and "VCM

Scanner", a data logging app. We like HPTuners because

it supports a wide range of GM engine controls platforms

and it's popular tuning software amongst DIYs and

professional calibrators, alike. HPTuners runs on PCs

using Windows XP, 7 or 8. At Tom Henry Racing, we run it

on an old Acer 5670 laptop loaded with Win 7.

In Part 5, we didn't

have a wideband oxygen sensor on the car, yet, so we

confined our tuning to some part throttle work which can

be done with the OE narrow band sensors. We began our

cal work for this article with a look at what the engine

was doing at wide-open throttle. The car has never felt

quite right at high-rpm. Not that it ran poorly–it just

didn't feel right, especially, when running above 5700

rpm on a cool day at sea level.

|

|

|

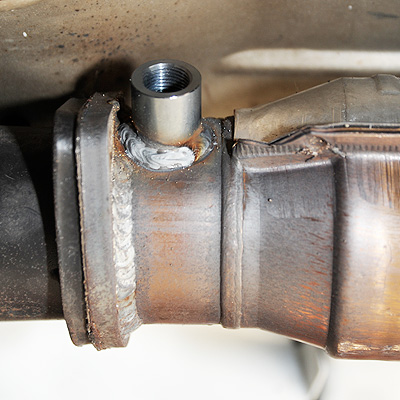

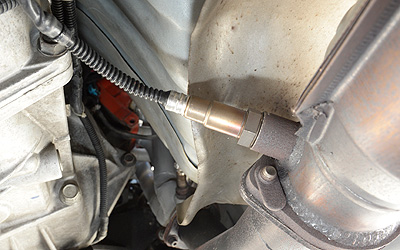

To install an

O2S bung, the exhaust is drilled just downstream of the

2-into-1 collector and just ahead of the catalytic

converter. The hole is deburred, then the sensor bung is

welded in place. Image: CHpg Staff.

|

|

|

|

Packaging

constraints dictated that we have the sensor bung

pointing to the center of the car. Image: CHpg Staff. |

A wide-band oxygen

sensor is required for calibrating wide-open throttle,

so the first thing to do was install one. We took the

car to Big John's Performance Center and had their ace

fabricator, Steve Munson, install an MSD oxygen sensor

bung in the exhaust just ahead of the catalytic

convertor. Then, we ordered Bosch Aftermarket (PN 17014)

and Denso (PN-234-5117) wide-band sensors from

RockAuto.com.

|

|

|

Initially, we

tried the recommended Bosch sensor with the LC-1. Image:

CHpg Staff.

|

We also ordered an

Innovate Motorsports LC-1 controller (PN 3744) from

Summit. Innovate markets a variety of wideband systems

and was suggested to us by the Tuning School which is

discussed in our sidebar about learning calibration.

|

|

|

We installed the

Bosch wideband sensor then looped the cable up and over

the exhaust. Image: CHpg Staff.

|

|

|

|

In a

perfectly-sized spot between the floor

and the exhaust shield, we mounted the

LC-1. Since this was a temporary

installation, after we shot this image,

we clamped the unit in place.

Image: CHpg Staff. |

We connected the

LC-1, HPTuners' "MVPI" (short for "multi-vehicle

protocol interface") which comes with the VCM Suite, an

LED indicator, a push-button and a wiring harness we

fabricated according to Innovate's and HPTuners'

instructions. All that links to our laptop with a USB

cable. While Innovate Motorsports supplies its own data

logging software, so we could log wideband and engine

controls data together; since we chose the uplevel "MVPI

Pro" which as the capability of logging data from up to

four 0-5-volt, external sources, we could configure VCM

Scanner, to record the LC-1.

|

|

|

HPTuner's

standard MVPI, the Pro model looks the same except for

the MPVP Pro has a, green, push-in connector on the

side. Provided they have analog outputs of from 0 to

5-volts, up to four external devices which you wish to

log can be wired to that connector. Image: CHpg Staff.

|

We screwed a Bosch

sensor into the Camaro's exhaust, set up HPTuners VCM

Scanner to display the wideband data then headed for

Westech Performance Group and its Superflow chassis

dyno.

We made three runs.

Afterwards, studying wideband data from VCM Scanner, I

could see we still had problems with power enrichment

(PE). At the low end it was at 0.86-lambda, which is

about right, but then, it would get rich until around

5500 rpm after which, the mixture would begin to lean

out. It would get back to .86λ then continue going lean.

|

|

|

With the

LC-1 connected to the MVPI Pro though the wiring harness

we fabricated, we can look at wideband data in synch

with other engine controls data using VCM Scanner.

Image: CHpg Staff. |

While we had done

some work to the "PE Fuel Adder RPM vs. Time" table for

Part 5, we were still having problems with rich mixture

once PE was enabled, so we just zeroed that table for

WOT periods shorter than 19-seconds then ran a few more

dyno passes. Starting at 4750 rpm, VCM Scanner showed

high injector duty cycles–understandable considering, at

the time, we were making around 270-hp with injectors

sized for 200. In fact, as we approached the rev

limiter, the system was commanding over 100% duty cycle,

which, of course, is impossible to achieve, because, at

100%, the injectors are held open.

|

|

|

Our choice was a set of RC Engineering

SL2-0240, 240-cc/min. injectors. Image:

CHpg Staff. |

We asked RC

Engineering, a leading supplier of aftermarket injectors

for help. RC's John Park told us not only did we likely

need injectors capable of flowing more fuel but that

fuel mixture can get erratic above 80-85% duty cycle for

extended periods because injectors overheat and may

become difficult to control. RC Engineering recommended

upgrading to a 240-cc/min. injector (PN SL2-0240) which

is a noticeable jump in fuel flow over the stock

206-cc/min, Delphi injector. RC injectors use the disc

fuel metering system, have corrosion-free, stainless

steel internal parts and are known for their tight

tolerance of flow spread (±1.5% or less) over a set of

six injectors. All sets of RC injectors are tested

before shipping and ours our went out the door with an

even better, 0.3% spread.

|

|

|

Every set of injectors is tested by RC

Engineering's John Park. Injectors, in

groups of up to four at a time are

tested for flow and spray pattern.

Image: CHpg Staff. |

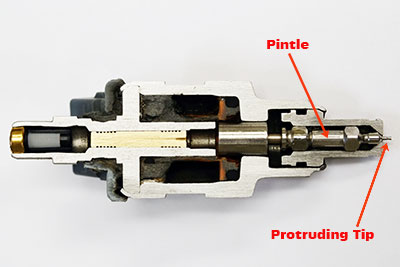

What are the chief

advantages of RC injectors over the more common and,

admittedly, less expensive Bosch pintle injectors?

First, the disc injectors are less prone to fouling. The

pintle is a long shaft with a needle-like tip which

sticks through a hole in the bottom of the injector.

When the injector is energized, this pintle lifts and

fuel flows between its tip and the edges of the hole.

When the engine is

shut off, some intake valves are left open. Heat from

inside cylinders with open valves rise to the injector.

If there is fuel residue on the pintle tip protruding

from the end of the injector, the fuel residue begins to

bake onto the pintle. Also, carbon byproducts of

combustion can collect on pintle tip. Over time,

baked-on fuel residue and combustion byproducts may

build-up, causing poor spray pattern, lean mixtures,

drivability quirks and high emissions.

|

|

A cutaway Bosch-type, pintle injector.

Image: RC Engineering. |

|

|

|

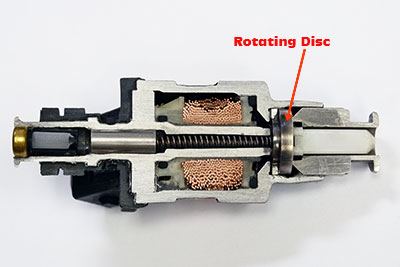

A cutaway of an RC Engineering, rotating

disc injector. Image: RC Engineering. |

When a disc injector

is energized, a tiny disc is raised off a seat and fuel

flows between the two. When the disc is off the seat it

may rotate. This type of injector is more resistant to

fouling because the disk and its seating surface are

recessed in the body of the injector and that has them

less exposed to heat.

The second advantage

comes from a difference in the mass of the injector's

moving parts. The disc's mass is about an eighth of that

of a pintle, thus disc injectors can respond more

accurately to short open times typical of idle and part

throttle operation. That gives disc injectors a wider

dynamic range.

|

|

|

While the Delphi and RC injectors have

different overall lengths, the distance

between the injectors' O-rings is

similar and the RCs will fit with no

problems. Image: CHpg Staff. |

|

|

|

The RC injectors push into the same

mountings in the fuel rail as did the

stock Delphi units. Image: CHpg Staff. |

|

|

|

Once you remove the alternator, getting

the fuel rail and injector assembly on

and off is easy. With its RCs in place,

we reinstalled the fuel rail. Image:

CHpg Staff. |

Installing

RCEngineering injectors is no more difficult than

replacing stock fuel injectors. Both types fit the stock

fuel rail and the injector mounts in the lower intake

manifold. Once you get the alternator and the ignition

system out of the way, use shop air or a shop vacuum to

remove any dirt and debris which might have accumulated

around the injector bases. Then, remove the fuel rail

and injectors. Remove the injector retaining clips, pull

out the old injectors. Then clean out the rail, install

the RCs, put the clips back on and reinstall the fuel

rail to the engine.

|

|

|

There is one feature which is quite

different on an RC injector and that's

its electrical connection. Initially, we

thought we'd have to splice and solder

the right connectors in to the THRS'

wiring harness which would preclude us

ever switching back, however, we

discovered that our fuel pump supplier,

Racetronix, sold "plug-and-play"

adapters which connected between the

stock wiring harness and the

RC injectors so we ordered a set of six

adapters. Image: CHpg Staff. |

The only feature of

these injectors that's different from stock are the

electrical connectors.The RC disc injectors use a

"minitimer" connector, whereas stock 3800 Series II

injectors use the "Multec II" connector. To make the

installation "plug-and-play," we ordered six Racetronix

adapter harnesses (IA-M2M) and connected them between

the OE injector connectors and the RC Engineering

injectors.

Calibrating for the

new injectors required a session on the RC Engineering

web site at

www.rceng.com

using its fuel flow and pressure calculator. We

converted our RC Injectors' 240-cc/min@43-psi flow

rating to what flow would be at the V6's observed,

50-psi fuel pressure–259-cc/min. Next, we converted that

into pounds-per-hour and using HPTuners VCM Editor,

entered 24.6-lb/hr. into the calibration as the flow

rate at zero manifold vacuum–wide open throttle.

A 3800 Series V6

calibration has injector flow numbers which vary

according to the effect manifold pressure has on the

injectors and on the fuel pressure regulator. To

populate this table with 100% accuracy, you'd have to

either flow test the injectors at a variety of MAP

levels and fuel pressures which, of course, is

impossible–unless you are GM Powertrain. We did the next

best thing: we figured the differences in flow on a

percentage basis for the stock injector flow data, then,

using those percentages, figured new data for the RC

injectors to put in the "Injector Flow Rate vs Kpa

vacuum" table. Finally, I programmed the pulse width

voltage offset data RC Engineering's John Park supplied.

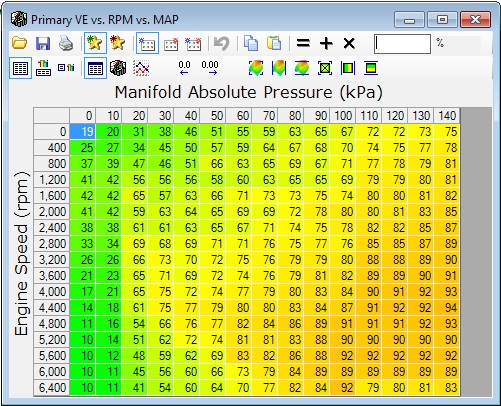

This time, testing

showed that, at WOT, the air:fuel ratio was now more

consistent so, the next step was to reconfigure the

calibration's main VE table at high throttle openings to

better suit the changes in airflow caused by the

aftermarket camshaft profile, larger valve sizes, head

porting and intake manifold Extrude Honing.

|

|

|

This is how HP Tuners displays the main

VE table. Changes can be made directly

in each cell. Any engine which has had

mods, such as a camshaft change, which

affect its volumetric efficiency, will

likely need tweaks to the main VE table.

Image: CHpg Staff. |

Some DIYs marginalize

the value of getting the main VE table right. Those who

do are either too lazy to do the work or don't

understand the need. If the VE table is stock, but your

engine has mods which affect volumetric efficiency, the

engine controls are going make incorrect assumptions as

to the amount of air entering the engine. Some rookie

calibrators use other methods to fool the engine

controls into delivering the right amount of fuel. This

may result in an inconsistent AFR when in PE and it does

not address the effect an inaccurate main VE table has

on part throttle drivability.

To get the VE table

right, be it on the dyno or on the test track, you have

to write a temporary calibration to the ECM which

disables the MAF sensor, has the high octane spark data

in the low octane spark table and is an open loop cal.

You, also, have to set-up your wide band to send data to

HPTuners and you need to program VCM Scanner to compute

and display "Lambda error" which is the difference

between the air:fuel mix the calibration commands

compared to what the actual air:fuel mix is according to

the wideband O2S.

Based on wide-band

data we took with VCM Scanner, during several test

sessions, we incrementally altered the Main VE table.

Once we had a "final candidate" written into a new cal,

we restored MAF sensing, spark tables and closed loop

fuel control.

While our WOT

air:fuel mix was more consistent because of the RC

Engineering injectors and the revised Primary VE table,

it was now a tad rich so we took a little fuel out,

across-the-board, then tested again to find the engine

at 0.85-0.86λ from 2000-6200 rpm and the maximum

injector duty-cycle at about 85%.

|

|

|

Getting the main VE table in shape,

first, makes any subsequent calibration

changes made to enhance drivability

easier to accomplish. The end result is

a car that runs well when your foot is

flat to the floor but also runs well at

high-part exiting turns.

Image: CHpg Staff |

During this test

session, we were running straight 91-oct gas in very

good (sea level, 68°F) air. In VCM Scanner data, at high

manifold absolute pressure (MAP), I noted consistent

knock retard (KR) between peak torque and peak power. To

verify it was real detonation and not false knock, I

added some Rockett Brand 100 Unleaded Racing Gasoline

and detonation was reduced. So the engine would run with

less KR on pump gas, In the main spark table cells

around peak torque at high MAP, I reduced the spark

advance by 2° then dropped the surrounding cells by 1°

and tested again. KR was reduced. Finally, I increased

the rate of knock retard decay–how quickly the system

puts timing back in after a KR incident ends–by 50%.

Both those changes

improved the knock retard situation on pump gas. With

the dip in the spark curve around peak torque and faster

KR decay, when using pump gas, which is the vast

majority of the time, the car ran better.

The last major

calibration issue we worked on was mass air flow. Some

who know enough to be dangerous about tuning minimize

the importance of getting the MAF tables right, but know

this: much of the computation the ECM makes about fuel

flow depends on measurement of the air flow going into

the engine. Some might be familiar with the adage:

"garbage in–garbage out." That certainly applies to MAF

cals. If you don't have the MAF cal right, you won't

have the engine's fuel delivery correct.

Why do we need to

optimize the MAF cal? Anything you change ahead of the

MAF sensor affects the accuracy of the data it sends.

The Tom Henry RS has an Whisperlid aftermarket air

filter top, a Green Filter and the stock air intake

resonator had been removed. All of that makes for a

change in how air gets through the MAF sensor.

Work with the MAF

calibration can be a little tricky because the ECM

toggles back and forth between the MAF sensor data and

plain old speed/density computation anytime the engine

is in a transient condition–for example: throttle

opening changing and the ECM adding fuel–when that

happens, the ECM may disregard MAF data and that can

effect data you're scanning. For that reason, whether

you're calibrating on the dyno or the test track, how

the vehicle is driven is key. The smoother you are

during acceleration testing the better.

Once again, we set up

HPTuners VCM Scanner to read lambda error then

configured VCM Scanner's histogram function to show that

error for each MAF frequency cell. You also have to

force the engine to run in open loop and zero the fuel

trim values. You will not obtain accurate data if you

don't do that.

We did our MAF

testing in several sessions divided into high throttle

opening and cruising. It took a while but we got are MAF

Lambda error down to ±.02, far better than the .08-.12

we started with.

For more on how to

learn basic tuning, read a sidebar by clicking here.

SS Hood

We've always wanted

an SS hood for the Tom Henry RS. We spent a couple of

months trying to find an original SS hood but gave up

once we saw the cost. Even damaged SS hoods were going

for 700 bucks.

Clearly, the best

choice for our budget was a fiberglass reproduction.

After researching the market a bit, we went with the SS

hood RKSport sells. One reason why we picked the "RK

Competition Ram-Air Hood" (PN 01011104) is the way it's

made. Tom Baker, RKSport's Director of Marketing, told

us, "All our hoods are hand-laid, not gunned or infused.

The fiberglass is sealed with marine grade gel coat and

the hoods ship 'paint-ready'–they just need a light

scuffing and primer before they're shot with paint and

clear coat. They're all manufactured at our facility in

Murrieta, California."

|

|

|

The RKSport hood came out of the box

nearly ready to paint. Image: CHpg

Staff. |

|

|

|

Before any significant finishing work

was done, the guys at Diamond Finish

Auto Body, test fitted the hood on the

Tom Henry RS.

Image: CHpg Staff. |

Besides the look and

how they are made, another reason we picked the RKSport

hood is the cold air ducting inside the O.E. SS hoods is

reproduced on its underside. The hood scoop is

functional with incoming cold air split between two

ducts which channel air to the our Whisperlid air filter

top.

|

|

|

The test fit confirmed RKSport's

"first-time-fit". Image: CHpg Staff. |

|

The final work on the

Tom Henry RS was done at THR's West Coast development

facility so we had RKSport ship the hood to our bodywork

specialist, Diamond Finish AutoBody in Santa Barbara,

California, for installation and painting.

At Diamond Finish,

during a test installation before any sanding, we found

the fit of RKSport's reproduction of the SS Hood to be

quite good. The only significant difference came at the

left front corner of the panel. To get the panel gap

correct at that spot, we had to shim the left side of

the front fascia up about an 1/8-inch. The RKSport hood

is not drilled for the stock hinges' locating tabs.

While ten minutes with a drill will fix that, we asked

Tom Baker why there were no holes for the tabs. He told

us that if one bends the tabs on the hinges flat, the

rear of the hood has a much greater range of adjustment

as to its position in the hood opening, so they leave

the tab holes undrilled figuring installers will do that

and have more adjustment–smart guys at RK Sport. |

|

|

|

A small amount of sanding and priming

was done to the edge of the hood at the

front. Image: CHpg Staff. |

|

|

|

After that, it was into Diamond Finish's

spray booth for a coat of white and then

a clear coat. Image: CHpg Staff. |

The crew at Diamond

Finish sanded and primed the hood then shot it with

Arctic White. After painting, the hood was installed

using the lower pressure struts RKSport includes with

the hood. A laser-cut, polished, stainless steel grille,

also, comes with the hood and is installed over the hood

scoop opening. The polished stainless didn't look good

on a white car with a black front grille insert so, we

had our long-time coating vendor, Extreme Performance

Heat Coatings, put a satin black coating on the grille.

|

|

|

Not only did the RKSport Competition

Hood do much to toughen the THRS's look

but its functionality was shown in our

road testing. Image: CHpg Staff. |

|

|

|

In fact, the Tom Henry RS came out

looking "tough" from just about any

angle. Image: CHpg Staff. |

For-Real Ram Air

With the new hood, I

decided to retest with the wideband O2 to see if the

hood made any difference in airflow into the engine.

Oh boy, did it ever!

I was astonished to

find that at highway speeds, the RK Competition Ram-Air

Hood increases air flow through the MAF sensor by 5-6%.

In fact, I had to, once again, tune the high end of the

MAF table in the calibration because, at high throttle

openings the engine went lean–Lambda .89-.92. Once we

did that, the WOT air:fuel was back at the ideal

.85-.86λ we like to see. Too bad we can't properly

duplicate the airflow into that hood on the chassis

dyno. I'd love to see how much of a change in power

output that hood is worth.

|

|

|

After the hood installation and some

final cal work, it was back to WesTech's

Superflow Chassis dyno. Image: CHpg

Staff. |

Back at Westech

Performance Group for some final numbers, it was hot

day. As knock retard hedge, I added enough Rockett Brand

100 Unleaded to bump the octane to 93. In three runs on

Westech’s AutoDyn, we were at 0.84-0.87 λ. We, also,

made our best SAE-corrected, rear-wheel power and torque

yet: 244.9-hp@5750-rpm and 234.5lbs/ft@4700-rpm,

SAE-corrected. That is just under 17-rwhp and 14-rwlb/ft

torque more than we did in our last chassis dyno test in

Part 5–a significant improvement. Using a .82 correction

for driveline loss, that's about 299-hp and 280 lbs/ft,

SAE, at the flywheel. Not bad for a 3.8-liter V6 which

started at 200-hp.

Next, we ran some

quarter-miles at our test venue. We use a Vericom VC3000

Performance Testing Computer to measure the car’s

performance. Vericoms have three major components: an

accelerometer, a crystal clock and a microprocessor. The

first two measure acceleration and elapsed time and the

third calculates velocity every 1/100 second. Knowing

the velocity and the time enables the VC3000 to

calculate distance every 1/100 second.

Suction cups or, for

some models more powerful vacuum cups, attach a Vericom

to the windshield. It can be installed in less than a

minute. It runs on an internal battery or off the car

battery via a 12-volt power cord. An “OBD2” cable is

available so the Vericom can recored engine controls

data along with vehicle dynamics data.

The VC3000’s accuracy

and dependability is such that it is used as a braking

test device in traffic accident investigations

worldwide. Vehicle manufacturers, tire companies, law

enforcement, transit companies and training academies

all use them. Vericoms are approved by the Federal

Aviation Administration to measure runway friction. A

test of a runway’s traction–or lack thereof– is

information required for pilots of commercial aircraft

landing in bad weather. Vericoms are widely used in the

United States for that purpose.

The unit’s accuracy

is 1% in time, g-force, speed and distance. In

acceleration testing, the difference between a Vericom

time and drag strip clocks is typically .2 to .4 sec.

and comes from the VC3000 not having a “roll out” delay

before timing begins. The later model of the Vericom,

the VC4000, does, in fact, have a “roll-out correction”

which defaults to 12-inches but can be user-adjusted for

other values.

With the Vericom in

the Tom Henry RS we headed for our test venue. In three

quarter mile passes, we averaged 15.22/96.90. To equate

that to drag strip timing, we’ll subtract .3 sec. for

the lack of roll-out to get: 14.92 No doubt, if we were

going to do another part of the series, we'd trade the

stock 3.23 axle ratio for a set of 3.73s then put some

drag radials on and have a 13-second car.

Finally, we took the

Camaro to a California Smog Check station and had it

tested. The engine tested clean by a significant margin.

Spray

The Tom Henry RS's

final engine modification was nitrous oxide injection

from Mike Thermos' Nitrous Supply. We installed a

"Sportstar Universal EFI Dry Manifold Kit" (PN NS06100)

and a "WIde Open Throttle Switch" (PN NS25633). The

Nitrous Supply Dry Manifold Kit is for engines with

electronic throttle control and a vacuum-controlled,

return-type fuel system, however, because this kit is

not specific to a V6 Camaro, there were extras–mainly

fasteners, some 3/16 fuel hose, an extra 7-ft. of AN-4

nitrous hose and fittings–necessary to get it working.

With the Sportstar

Kit, nitrous is injected just downstream of the throttle

body's MAF sensor. Extra fuel is supplied through the

injectors by increasing fuel pressure when the system is

active.

|

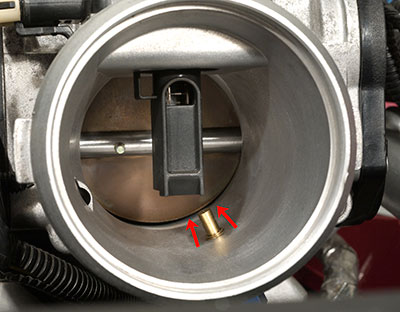

|

|

Nitrous Supply's Mike Flynn at work on

our throttle body. If you are very

careful, nozzle mounting can be done

with a hand drill. The TB material is

thin so, to ensure the nozzle doesn't

back out, use a thread locking compound

such as Permatex Medium-Strength

Thread Locker Gel. After nozzle

installation, thoroughly clean the TB to

eliminate any metal chips. Image: CHpg

Staff. |

|

|

|

It's critical that the nozzle point to

the rear of the TB. If it does not,

nitrous oxide can "bounce" off the sides

of the throttle body, causing errant

mass air flow sensor readings resulting

in significant problems with fuel

delivery. Take a fine-point Sharpie,

mark a line on the top of the nozzle

then tighten the nozzle until the line

points to the rear. Image: CHpg

Staff. |

The discharge nozzle

has to be installed in a specific spot in the throttle

body. While it is a task which can be accomplished by a

DIY with a drill press, we decided the job was better

done by Nitrous Supply. We pulled off the throttle body,

visited Nitrous Supply and had Mike Flynn install the

nozzle. Inside the discharge nozzle is the nitrous jet.

|

|

|

Nitrous nozzles have SAE 37° AN04

connections to which our braided

stainless steel covered Teflon hose

attaches.

Image: CHpg Staff. |

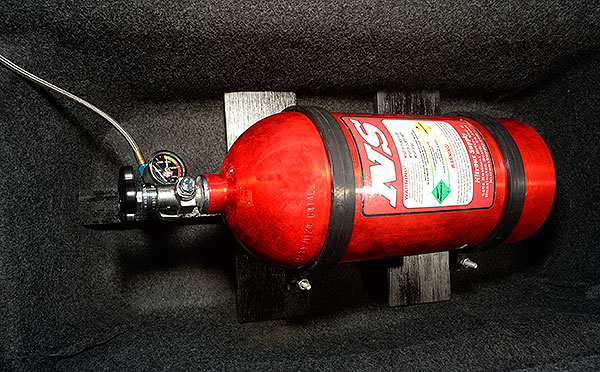

We put the nitrous

oxide cylinder in the cargo well behind the rear axle.

Using some wood we bought at Lowes and the two bottle

brackets that come with the kit, we built a mount which

held the bottle securely but could, also, be easily

lifted out when the space was needed for cargo. Our

bottle holder accepts either 10-lb or 15-lb Nitrous

Supply cylinders. The positioning of the bottle in the

brackets is key to optimal performance.

|

|

|

We built a wooden frame, painted it flat

black, bolted Nitrous Supply bottle

mounts to it and viola–a removable

nitrous bottle mount which fits nicely

in the Camaro's cargo well. We installed

the Nitrous Supply 10-lb bottle into the

mounting rings. Image: CHpg Staff. |

Under pressure,

nitrous oxide is a liquid. A nitrous bottle is made such

that its siphon tube extends to a point on the bottom of

the bottle opposite the center of the label. The idea is

to orient the end of the siphon tube such that

acceleration keeps the end of the tube covered with

liquid nitrous oxide. On a bottle, such as ours, located

perpendicular to the vehicle centerline with the

discharge valve on the driver side of the car, orient

the label so it is 30° from vertical towards the front

of the car. That puts the pick-up end of the siphon

tube, 30° towards the rear from the lowest point of the

bottle.

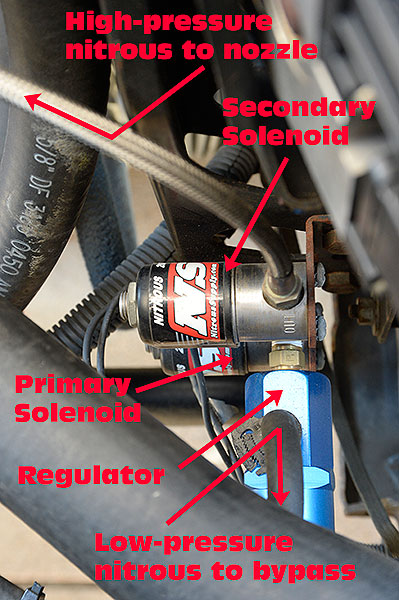

Next, we assembled

the "solenoid module" by installing a Nitrous Supply

solenoid on each end with the solenoid tee and the

nitrous pressure regulator in the center. We screwed the

solenoid module to the bracket that comes with the kit

and mounted that on the driver side, front subframe

rail, above and just behind the front stabilizer bar

mount.

|

|

|

We used the stock power steering

reservoir bracket to hold the pair of

Nitrous Supply solenoids and the

regulator. Image: CHpg Staff. |

|

|

|

This is the solenoid/regulator assembly

once the power steering reservoir

bracket is reinstalled on the left front

frame rail. Image: CHpg Staff. |

We ran the AN-04

braided stainless-steel-covered Teflon hose from the

solenoid module, along side the fuel and brake lines

which run down the driver side of the floorpan, to the

back of the car. In several places, we attached the hose

with zip ties. In places where this nitrous feed line

runs near our headers, we insulated it with Design

Engineering Heat Sheath (PN 010419). The hose included

with the kit was not long enough, so we added a Nitrous

Supply, four-foot, AN-04 extension. To get the hose into

the cargo bay, we temporarily removed one of the two

plugs in the bottom of the cargo well and ran the hose

through the hole. To keep the sharp metal edges around

the hole from cutting the hose, we sliced a three-inch

piece of plastic hose from our scrap bin lengthwise and

slipped that over the AN-4 where it touches the edges of

the hole. We removed the screw holding the left corner

of fuel tank's aluminum shield, tucked the nitrous hose

into the void between the tank and the shield then

replaced the screw. Finally, we dropped our custom-made

nitrous bottle mounting in the well and connected the

nitrous hose.

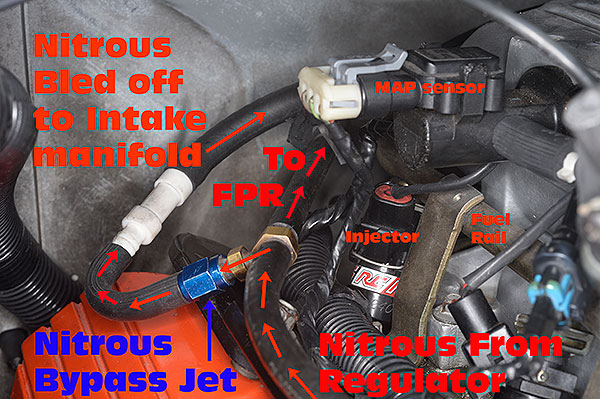

The Nitrous Supply

Sportstar EFI Kit is known as a "dry system" because

only nitrous oxide flows into the throttle body and

extra fuel comes through the fuel injectors. To meter

that extra fuel, nitrous oxide at greatly reduced

pressure, is fed to the stock fuel pressure regulator

(FPR) which causes fuel pressure to rise from the

approximate 50 psi normal for a 3800 V6 to 65-70 psi.

|

|

|

We mounted the Nitrous Supply "WOT box"

on top of the driver-side wheel house

just behind the underhood fuse block.

Image: CHpg Staff. |

The reduced nitrous

pressure fed to the FPR is accomplished in two steps.

The first takes place in the nitrous regulator between

the two solenoids. From the nitrous regulator, we ran

fuel injection hose across engine compartment behind the

cooling fans then, up to the top-right-front of the

engine and along the right rocker cover to the rear of

the engine. We installed the Nitrous Supply pressure tee

into the hose which runs from the intake manifold,

around the back of the intake plenum to the fuel

pressure regulator. The tee comes with a .042-in. jet in

it which bleeds off some of the nitrous flow from the

nitrous regulator, further reducing the pressure applied

to the FPR. The size of this jet can be varied to change

the air:fuel ratio when nitrous is flowing–smaller jet,

more fuel pressure; bigger jet, less fuel pressure.

The pressure on the

FPR generates more fuel flow, provided the fuel system

has been modified for adequate flow at the higher

pressure level and we accomplished that with the

Racetronix fuel pump (PN PN F99-FPKG-2) installed for

Part 4 of this series. Some DIY's don't understand the

relationship between fuel pressure and fuel pump

capacity. If you raise the pressure, the pump's fuel

flow limit decreases. If that decrease goes below the

engine's greatest required fuel flow, the engine will go

lean at high rpm. We raised the the engine's need for

fuel flow through our engine mods, then we raised the

system pressure. That overtaxed the stock fuel pump.

Hence our switch to a Racetronix.

|

|

|

The plumbing of the nitrous bypass and

the fuel pressure regulator gets a

little bit complicated but the system

works quite well provided the fuel

system is capable of the extra flow the

nitrous oxide system requires. Image:

CHpg Staff. |

Any nitrous oxide

system uses a relay to control the solenoids and Nitrous

Supply's system includes a 30-amp relay which we mounted

on the front of the inner fender. We wired the load side

of the relay to the battery and the solenoids.

We attached the

Nitrous Supply Wide Open Throttle Switch–"WOT box" for

short–on top of the left inner fender. It triggers

nitrous injection for an engine without a mechanical

throttle linkage by sensing throttle position sensor

(TPS) voltage and energizing the nitrous solenoid relay

just before maximum TPS. This voltage varies depending

on the engine. Using our shop's Fluke 88V DMM we

measured the TPS #1 voltage at wide open throttle and it

was 3.30-3.32v, so we adjusted the WOT Box to kick the

primary nitrous solenoid on at 3.28v. Finally, we

connected the box's output to the line side of the

nitrous relay.

Next, we removed the

cap from the fuel rail's fuel pressure connection. Then,

using a tire valve core tool, we took out the Schrader

valve core. Once the cap and valve were gone, we

installed the nitrous kit's extension tube, which adapts

the kit's fuel pressure safety switch to the AN-04

connection on the fuel rail, and screwed the switch in

place. Finally, we wired the fuel pressure switch

between the secondary solenoid and ground and routed the

switch wires along side to the hose running down to

nitrous regulator. When the system is energized, the

primary nitrous solenoid opens and nitrous oxide flows

through to the nitrous regulator and up the hose to the

tee and to the FPR. When the fuel pressure rises to 65

psi, the safety switch closes energizing the secondary

nitrous solenoid which opens, allowing gas to flow to

the discharge nozzle and into the throttle body. The

fuel pressure switch prevents nitrous oxide flow until

adequate fuel pressure exists.

|

|

|

The Nitrous Supply fuel pressure safety

switch is installed in place of the fuel

pressure test connection on the end of

the passenger side fuel rail. If you

remove a rubber plug on the top of the

switch, you can adjust its trigger

pressure with a hex key. The default

setting is 50 psi, but it must be

readjusted to turn-on 3-5 psi above a

V6's nominal fuel pressure range of

48-52 psi. The best way to do this is

test the engine's fuel pressure per the

Service Manual, then use a calibrated

air source to set the switch 3-5 psi

above the pressure you read. Image: CHpg

Staff. |

Nitrous Supply

includes a generic toggle switch for arming the system,

but we decided a neater installation would be a second

fog light switch (PN 10273879) in the panel above the

radio as an arming switch. We ordered one from the Tom

Henry Racing parts department, removed the plug

originally in the panel and popped the switch in place.

After that, we installed a push button, momentary switch

on the gear shift lever just below the shift knob and

positioned such that when the driver's hand is on the

knob, he can flick a thumb down and push the button.

We ran a hot wire

from the fuse panel to the master switch, then to the

button and from there, though the fire wall to the WOT

box. To get nitrous, the arming switch must be closed,

the throttle must be wide open, the driver must push the

button and the fuel pressure needs to be up.

|

|

|

These are the features we like in the

Denso Iridium Power spark plug. Image:

CHpg Staff. |

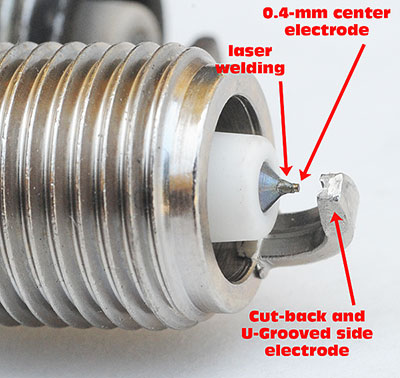

The last step in

preparing the car for nitrous was to install a fresh set

of Denso Iridium Power IT-20 spark plugs. We've used

Densos since the start of the Tom Henry RS series. We

like the Iridium Power design because it's a combination

of the best of Denso's two product lines, the

iridium-tipped plugs it makes for car companies–General

Motors being one of them–and its track-proven racing

plugs. A key feature of this Denso is the small, 0.4-mm

iridium center electrode. The advantage of an iridium

electrode over one made from more traditional platinum

is better durability and lower resistance. Another

obvious characteristic of the Denso is its ground

electrode which is cut-back, tapered and grooved. The

small center electrode and unique shape of the ground

electrode give the spark maximum exposure to the

incoming, air/fuel charge. In short, we think the IT-20,

which is a heat range colder than stock, is the best

spark plug choice for 3800s in street high-performance

and mild racing applications. For track only

applications, we'd use the even-colder, IT-22.

With all this nitrous

hardware installed, it was time to take the car out for

a little test run. Did it work? Damn right! When we

shifted into second gear, then squeezed the button–boom!

We got a serious, nitrous-fortified, kick in the ass.

The next step was to

verify the tuning of our newly installed Nitrous Supply

system. Testing with the Innovate Motorsports LC-1 found

that when the nitrous was working, the engine was a bit

rich–0.73-0.76-λ so–with some tuning, the nitrous hit

would be even bigger.

|

|

One more time on the WesTech dyno, this

time with spray, had us just short of

400-hp. Image: CHpg Staff. |

We decided the

nitrous flow was likely adequate but, because the

air:fuel was rich we weren't getting the full benefit.

We needed to lean the engine out to the 11 or 11.5:1

suggested by Nitrous Supply and, with the Nitrous Supply

Sportstar EFI system, you can do that by decreasing fuel

flow during nitrous operation.

First thing we did

was test what kind of fuel pressure we had when the

nitrous system was enabled. We installed our Waekon

digital fuel pressure tester (PN 48165) and went for a

road test. When we squeezed the nitrous button

and–wow–97-psi fuel pressure! No wonder the engine was

rich on the bottle.

With the nitrous

oxide system operational, additional fuel flow comes via

higher-than-atmospheric-pressure applied to the FPR

diaphragm. The size of the jet in the tee determines

that pressure. Ideally, you want the air:fuel ratio with

the nitrous system operating at about 0.80-lambda. That

is a little rich, but you need that richness to

compensate for inconsistent distribution of nitrous

oxide in the intake manifold.

We started by

doubling the diameter of bypass jet to .081-in. Fuel

pressure was still too high. We went up to .091-in. and

finally to .110-in. Fuel pressure was now at 70-lbs.

Air: fuel with nitrous oxide working was finally

hovering around .79-lambda.

We rolled the Tom

Henry RS on Westech's Superflow Autodyn for the final

time. Because the engine with nitrous oxide being

injected is more prone to detonation, we put a 2:1 mix

of Rocket Brand 100-oct Unleaded Racing Gasoline and

pump gas in the tank and let fly. On nitrous, the car

made 316.3 hp at the wheels at 5775-rpm and 325.8 lbs/ft

at the wheels at 3630-rpm, SAE-corrected. Those numbers

work out to 385-hp and 401 lbs/ft torque, SAE at the

flywheel. A 75-shot indeed! Actually, it's an "85" shot

and more than enough nitrous oxide for an engine with a

stock pistons and rings. Peak torque moving down 1000

rpm is a function of the increased cylinder pressure in

the mid-range which nitrous oxide can provide.

|

|

|

Image: CHpg Staff. |

Once again, we

installed our Vericom VC3000 and did some more

quarter-mile tests. With nitrous, the our Camaro went

13.65/100.43.

|

THRS Chassis

dynamometer test history

Rear wheel power,

SAE-corrected |

|

1) 162.3-rwhp–Stock

|

|

2) 173.5-rwhp–Stock

with Flowmaster exhaust |

|

3) 206.0-rwhp–DeGroff

ported big-valve heads, Comp Cam, Extrude Honed intake,

Extrude Honed stock exhaust manifolds, Flowmaster

exhaust, Z-Industries reprograming. |

|

4) 212.9-rwhp–DeGroff

ported big-valve heads, Comp Cam, Extrude Honed intake,

Dawson Headers, Flowmaster exhaust, Z-Industries

reprograming. |

|

5) 219.1-rwhp–DeGroff

ported big-valve heads, Comp Cam, Katech Valve Springs,

Extrude Honed intake, 1.8 rockers, Dawson Headers,

Flowmaster exhaust, Z-Industries reprograming. |

|

6) 228.3-rwhp–DeGroff

ported big-valve heads, Comp Cam, Katech Valve Springs,

Extrude Honed intake, 1.8 rockers, Dawson Headers, 3"

cat converter and S-pipe, Flowmaster exhaust,

Z-Industries reprograming. |

|

7) 244.9-rwhp–DeGroff

ported big-valve heads, Comp Cam, Katech Valve Springs,

Extrude Honed intake, 1.8 rockers, RC Engineering

injectors, Dawson Headers, Flowmaster exhaust, in-house

reprogramming. |

|

8) 316.3-rwhp–DeGroff

ported, big-valve heads, Comp Cam, Katech Valve Springs,

Extrude Honed intake, 1.8 rockers, RC Engineering

injectors, Dawson Headers, Flowmaster exhaust, nitrous

oxide, in-house reprogramming. |

Farewell to the

THRS

Clearly our Extrude

Honed intake manifold, RC Engineering injectors, Mark

DeGroff heads with Manley Valves, Comp Cam, Katech Valve

Springs, Dawson Headers, Flowmaster exhaust, our ECM

programming and the hardware from Nitrous Supply all

work very well.

After five years,

it's time to turn-off the lights and shut the door on

the Tom Henry RS. We've learned a lot about how to

improve performance and tune a 3800 Series II V6 for

high-performance street use and modify the fourth-gen

Camaro chassis for better handling and braking. We hope

you have too.

If you enjoyed this

series, let us know. If we hear from enough readers, we

might do an encore. Finally, we'd like to thank all of

our project sponsors for their support of the Tom Henry

RS project.

Project Sponsors:

|