|

Sidebar

Learning Calibration

Basics

|

|

|

Image: CHpg

Staff |

At Tom Henry Racing,

we've been doing custom tunes for years, but what if you

want to try calibration, yourself? Some gearhead

luddites whine, “Cars with computers–can't work on them.

Too complicated. Too expensive. And, tuning? You gotta

be kiddin' me. Only dealers or engineers can do that."

If you understand

what goes on inside your engine and you are

computer-literate enough to create an Excel spreadsheet;

you probably can learn to tune–or “calibrate,” as

engineers say–engine control systems.

|

|

|

Our initial

education about tuning work came from this book and

several others. Image: CarTech Books. |

|

How can you start

learning to tune? Well–there are several ways. You can

do an "internship" with an experienced tuner–fabulous

idea, but a rare opportunity. You can read Internet

forums–reasonable in theory, but in practice, be

cautious when reading calibration discussions because

there are forum members who know enough to be dangerous

and are quick to bloviate about tuning. Not to say

experienced calibrators aren't on-line–it's just they're

harder to find. You could try to learn by

trial-and-error–bad idea. You can read books, watch DVDs

or take classes. This is probably the way a cost

conscious DIY should learn calibration. |

Good reading on the

subject is Jeff Hartman's, How to Tune and Modify

Automotive Engine Management Systems, published by

Motorbooks. Additionally Greg Banish’s Designing and

Tuning High-Performance Fuel Injection Systems and

Engine Management: Advanced Tuning, published by

CarTech are excellent choices. Finally, Harold Bettes'

and Bill Hancock's Dyno Testing and Tuning and

GM Gen III Powertrain Control Systems by Mike

Noonan, also, from CarTech, are good books.

|

|

|

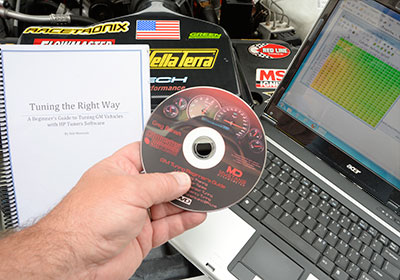

The Tuning School home-study material

(left) and the Calibrated Success

DVD-base classes (center) are both good

ways to learn about tuning, however,

their approaches are different and some

of the course material do not overlap.

As a result, we found both instructional

channels were valuable to us. Image:

CHpg Staff. |

There are home-study

courses. If you like reading, there is A Beginner’s

Guide to Tuning GM Vehicles with HP Tuners Software,

offered by the “Tuning School” of Odessa, Florida. If

you like watching, Greg Banish's Calibrated Success has

two good training DVDs which it sells through Summit

Racing. The first DVD, "GM Tuning Beginner's Guide",

covers basics such as tuning for aftermarket injectors,

MAF Sensors, volumetric efficiency. The Beginner's DVD

focuses use of HPTuners. Calibrated Success also has "GM

Tuning Advanced Guide" which covers tuning for

aftermarket cams, scaling, tuning ECMs with virtual VE

tables and other subjects.

The home-study books

have a few confusing statements and some lax

proofreading. The DVD's videography and editing were

substandard in spots. Nevertheless, the training from

both these courses is beneficial–particularly, the DVDs.

While all this instructional material is focused on V8s,

many techniques apply to calibrating V6es, too.

If you like the

classroom environment, both the Tuning School and

Calibrated Success offer classroom instruction. If you

can afford it, such training is even better. See their

web sites for more information.

All Dyno or Some Dyno

An issue which evokes

strong opinions amongst calibrators is how much work

must be done on a chassis dyno.

Some say the only way

to tune is with a load-bearing chassis dyno and anyone

doing it with road testing is a rank amateur. Others

make a case for only some of the work requiring a

chassis dyno with other tasks done on the test track.

Even the training

material we used seemed to differ on this issue with

Calibrated Success' DVD suggesting a load-bearing dyno

is the only way to get the job done right whereas The

Tuning School courses suggest it's practical to do some

work on the road.

We used a mix of dyno

runs and track testing because the cost of doing it all

on a dyno was prohibitive. We believe our practical

tuning needs were met, but we, also, agree that, to get

a "perfect" engine controls calibration may require a

lot of chassis dyno time.

Oxygen Sensor Basics

|

|

|

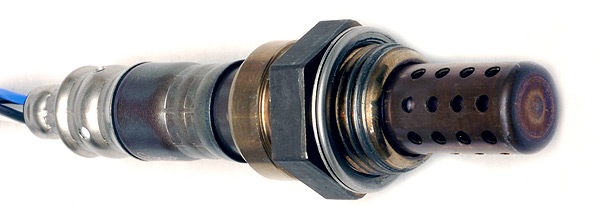

One

of the Denso narrow-band oxygen sensors

we use in the Tom Henry RS. (Image: CHpg

Staff. |

|

|

|

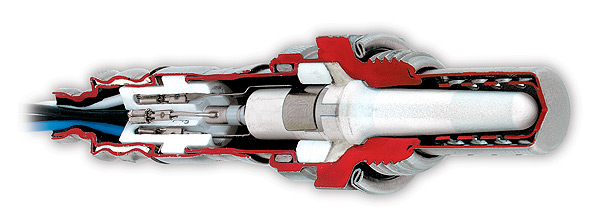

These are the guts of

a Denso oxygen sensor. The white part is the active core

of the sensor. In it is a device known as a "Nernst

cell". Its two electrodes provide an output voltage

corresponding to the quantity of oxygen in the exhaust

relative to that in the atmosphere. Image: Denso

Products and Services America.

|

An oxygen sensor

(O2S) measures the oxygen in exhaust gases. In 1976, the

"lambda" or "exhaust gas oxygen" (EGO) sensor for

automotive use was introduced by the Robert Bosch

Corporation. Most O2Ses are “narrow-band” devices. They

generate 100 to 1000 millivolts, depending on the level

of exhaust oxygen, however, their output is linear only

in the narrow band of voltages generated when combustion

is near stoichiometric. Outside a range of

0.97-1.06-lambda, the signal is nonlinear making useful

measurement when the engine is in PE impossible.

Wideband sensors,

developed by Bosch in the mid-1990s, vary a reference

voltage supplied by a controller. This produces a far

more linear output such that, given a low level of back

pressure, a "wideband" is accurate from 0.34 to 1.51 λ.

A wideband is required for calibrating at

wide-open throttle (WOT).

Learning Lambda

The DVD from

Calibrated Success taught us to think in "lambda," a

measure of free oxygen in the exhaust identified by the

greek letter "λ," rather than air:fuel ratio (AFR).

Combustion is

"stoichiometric" when neither unburnt hydrocarbons

(rich) nor excess oxygen (lean) are present in the

exhaust. When combustion is "stoich," lambda=1 and the

engine produces low exhaust emissions, high catalytic

converter effectiveness and good fuel economy.

Stoichiometric is 1.00 λ regardless of fuel type,

whereas AFR varies. For example: stoich for pump gas is

often said to be 14.68:1, but actually varies

14.55-14.8:1 depending on humidity and the gasoline

blend. "Indolene Clear," an emissions test fuel used by

car companies, is stoich at 14.56:1 and that value

sometimes appears in GM calibrations as a reference.

Oxygenated gasolines containing up to 10% ethanol, (aka

"E10"), are 14.08-14.25:1. Another, E85, which is

popular with racers, is 9.87:1. If you think lambda, at

1.0 λ; they're all burning stoichiometrically.

When an engine is

under high load, its air: fuel ratio must be rich to

prevent excessive combustion temperature and detonation.

Calibrators call this "power enrichment," or "PE" and,

on straight gasoline, it's about 12.5:1, air:fuel. With

E10, it's about 12.2:1 and with E85 it's 8.4:1. If

you're using lambda, in PE, those are all 0.84-.0.86 λ.

Thinking in Lambda

makes calibration easier.

Fuel and all the

Trimmings

When engine controls

operate in "closed loop," they “trim” fuel flow by the

amount necessary to have combustion as close to 1.0 λ as

possible. If the base fuel schedule has the engine

running about 1.0 λ, trim values are mid-scale, usually

designated 128 or 0. If lambda is less than 1.0, the

engine is rich, so the system decreases fuel flow to

bring combustion back to stoichiometric and the trim

numbers will be lower. If lambda >1.0, the engine is

lean, so the system increases fuel flow and the trim

numbers are higher.

There are two kinds

of fuel trim, "short term" (STFT) and "long term"

(LTFT). The first changes quickly and is not retained in

memory. If the ECM detects a trend in STFT, it transfers

that to LTFT, which is retained in memory, such that

STFT varies from zero, less often. The total fuel trim,

short-term plus long-term, is added to the base fuel cal

to keep combustion stoichiometric.

Finally

The instructional

material might take a week or so to digest. After that,

with HPTuners' VCM Editor, you can download a

calibration from your Camaro or Firebird and start

practicing the techniques you learned.

In couple of weeks,

you'll be ready to "flash" the car's computer with your

first calibration. Indeed, you'll have more to learn,

but you'll know the basics.

< Return to Part 6

|